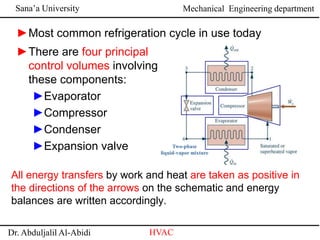

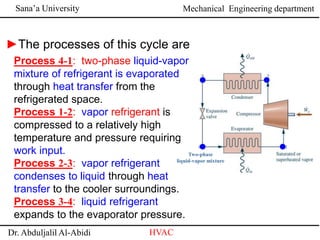

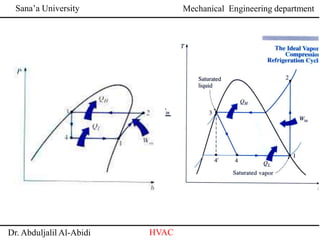

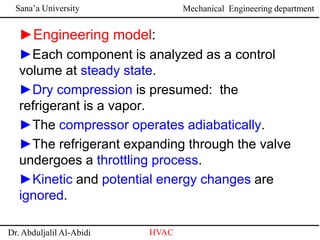

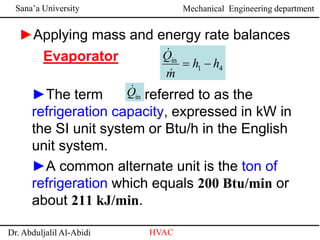

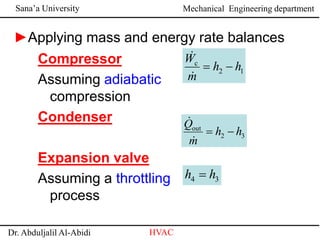

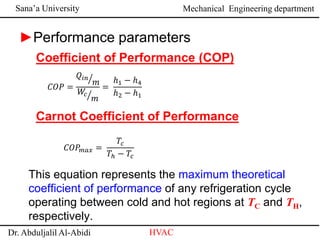

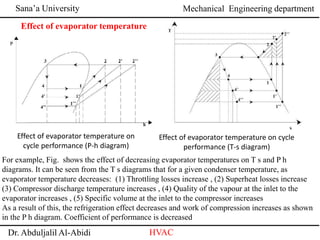

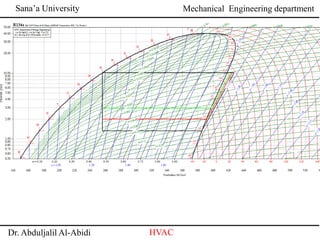

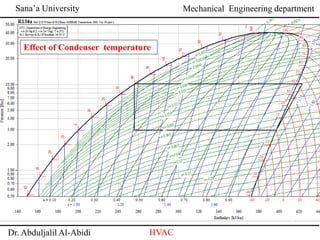

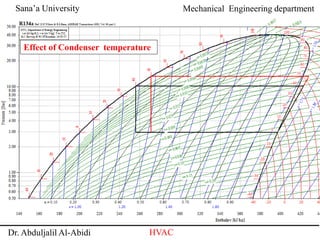

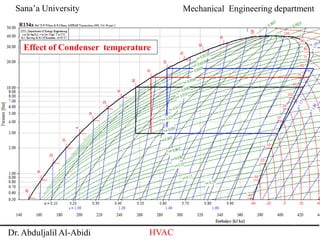

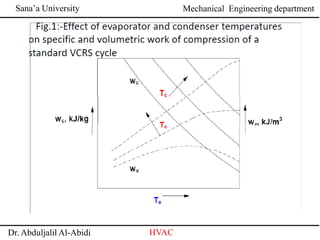

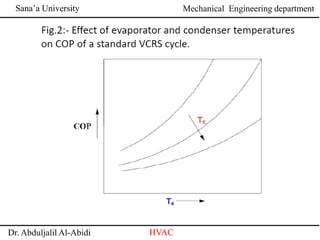

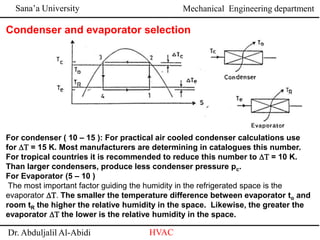

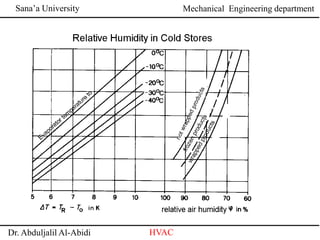

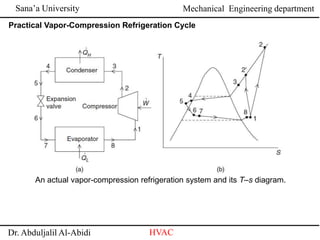

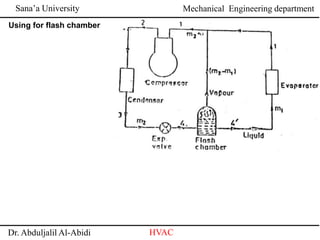

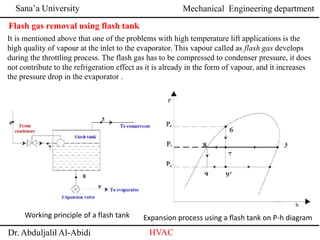

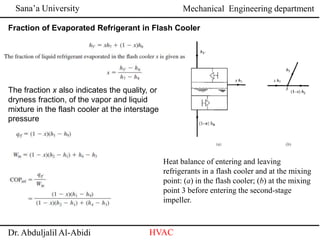

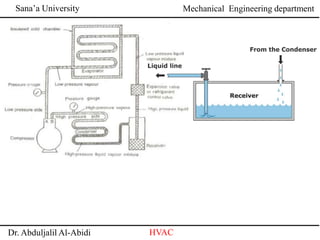

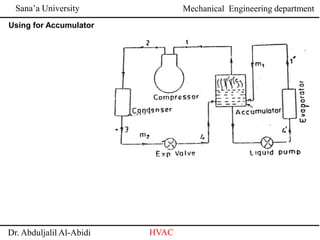

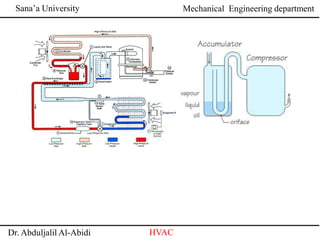

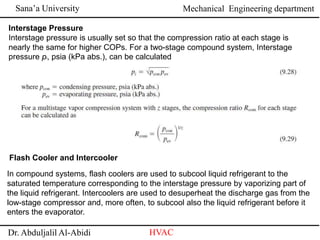

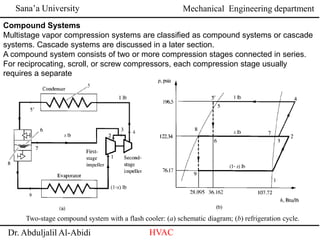

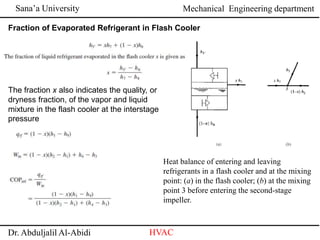

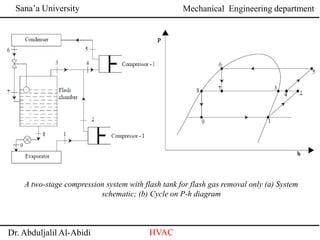

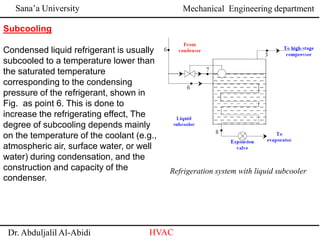

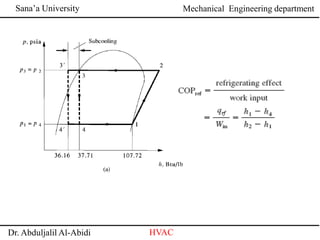

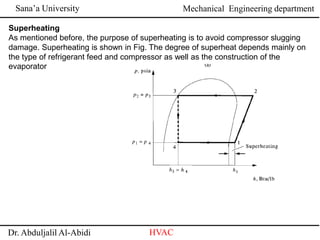

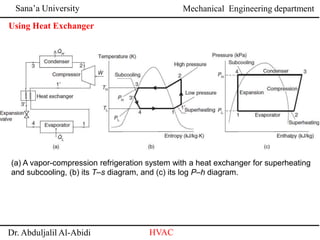

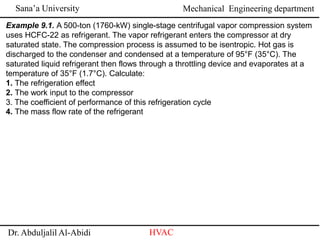

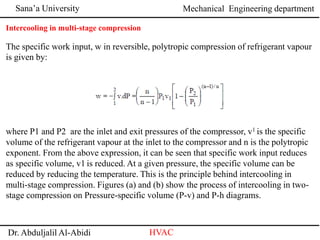

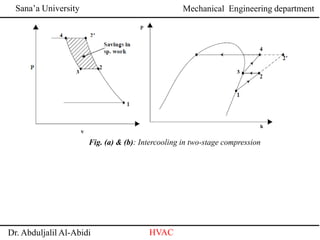

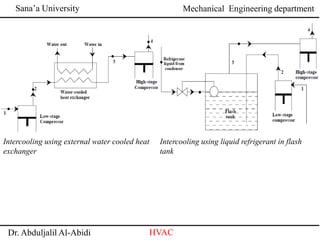

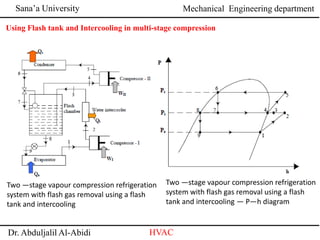

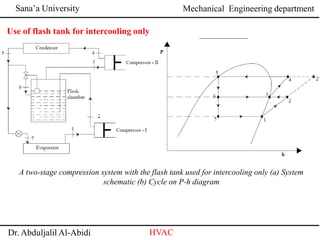

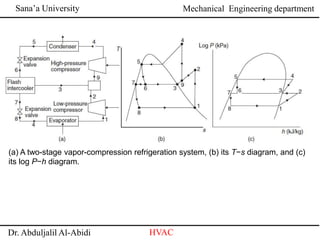

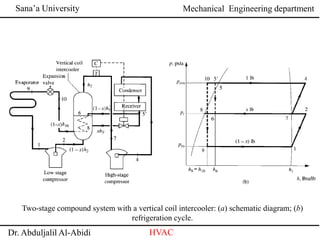

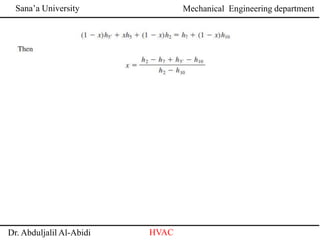

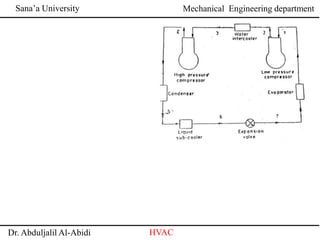

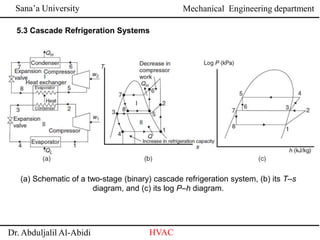

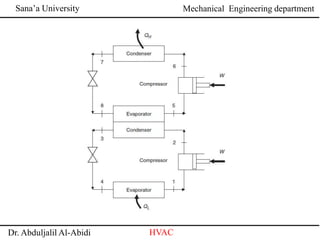

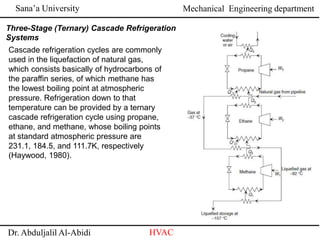

This document discusses vapor compression refrigeration systems from Sana'a University in Yemen. It covers topics like coefficient of performance, the basic refrigeration cycle with four main components (evaporator, compressor, condenser, expansion valve), processes within the cycle, effects of evaporator and condenser temperatures, examples of cycle analysis, use of flash tanks and accumulators, and multistage compression systems. The document is presented by Dr. Abduljalil Al-Abidi from the Mechanical Engineering department and focuses on vapor compression refrigeration taught to students.