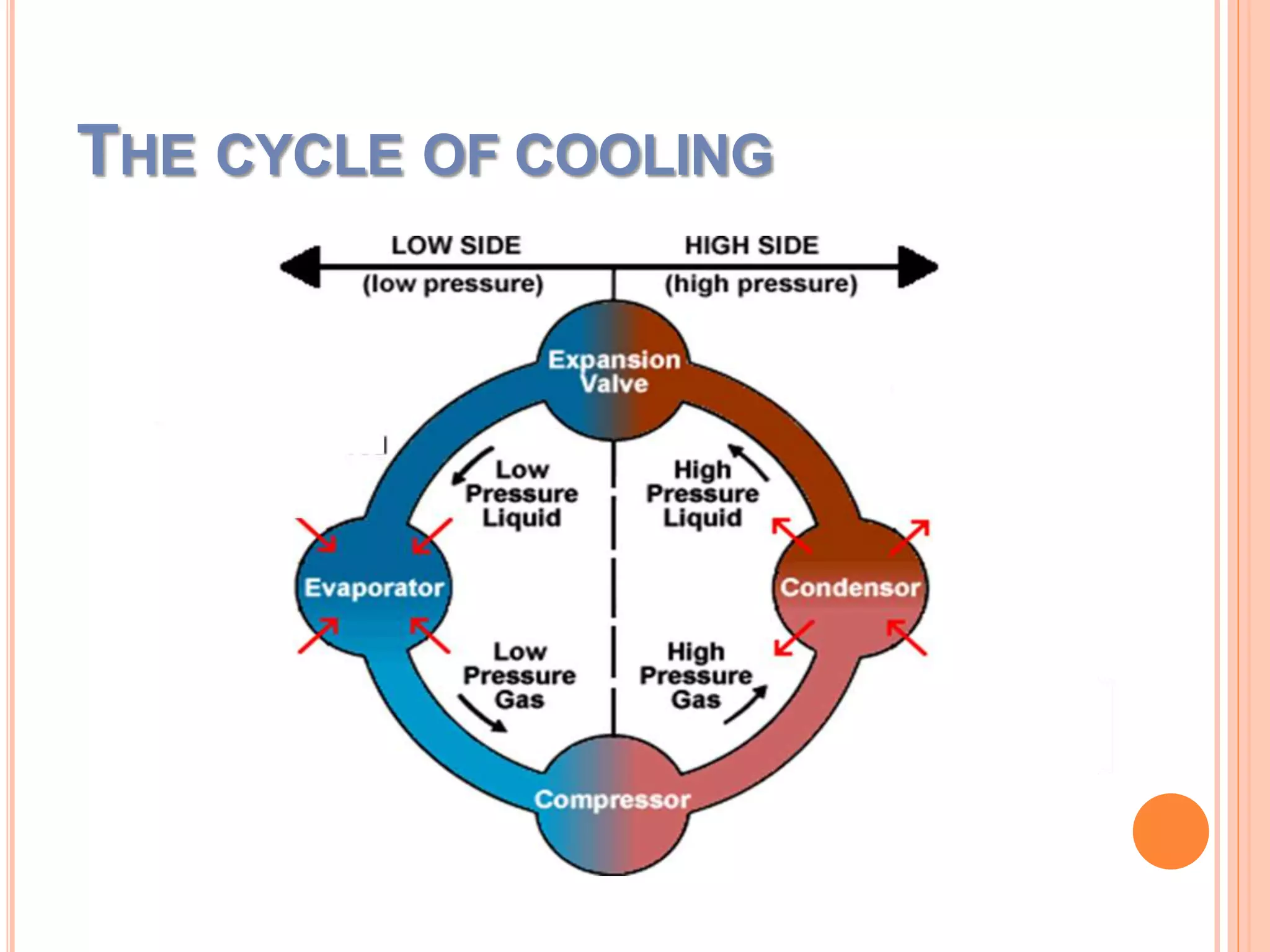

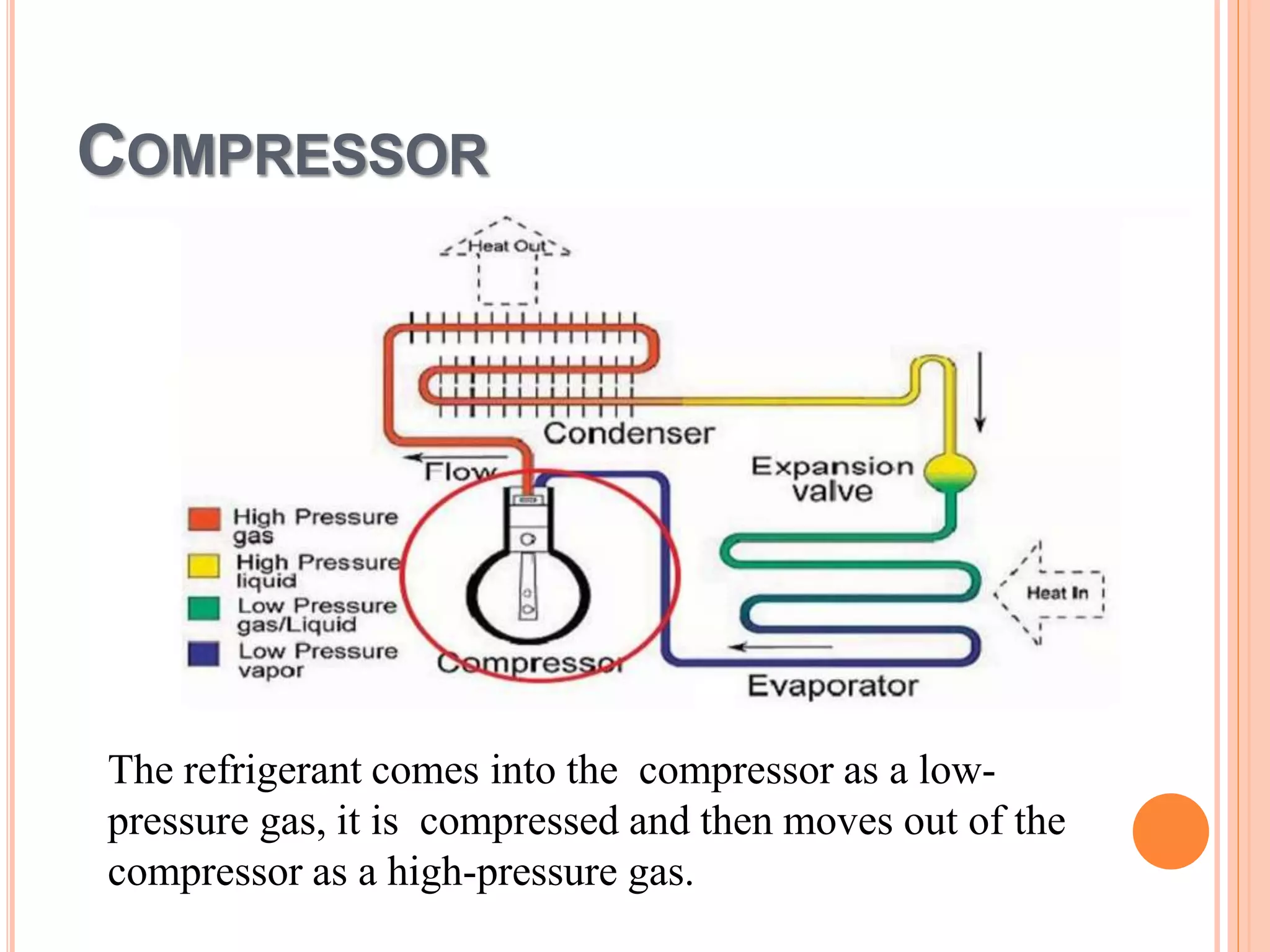

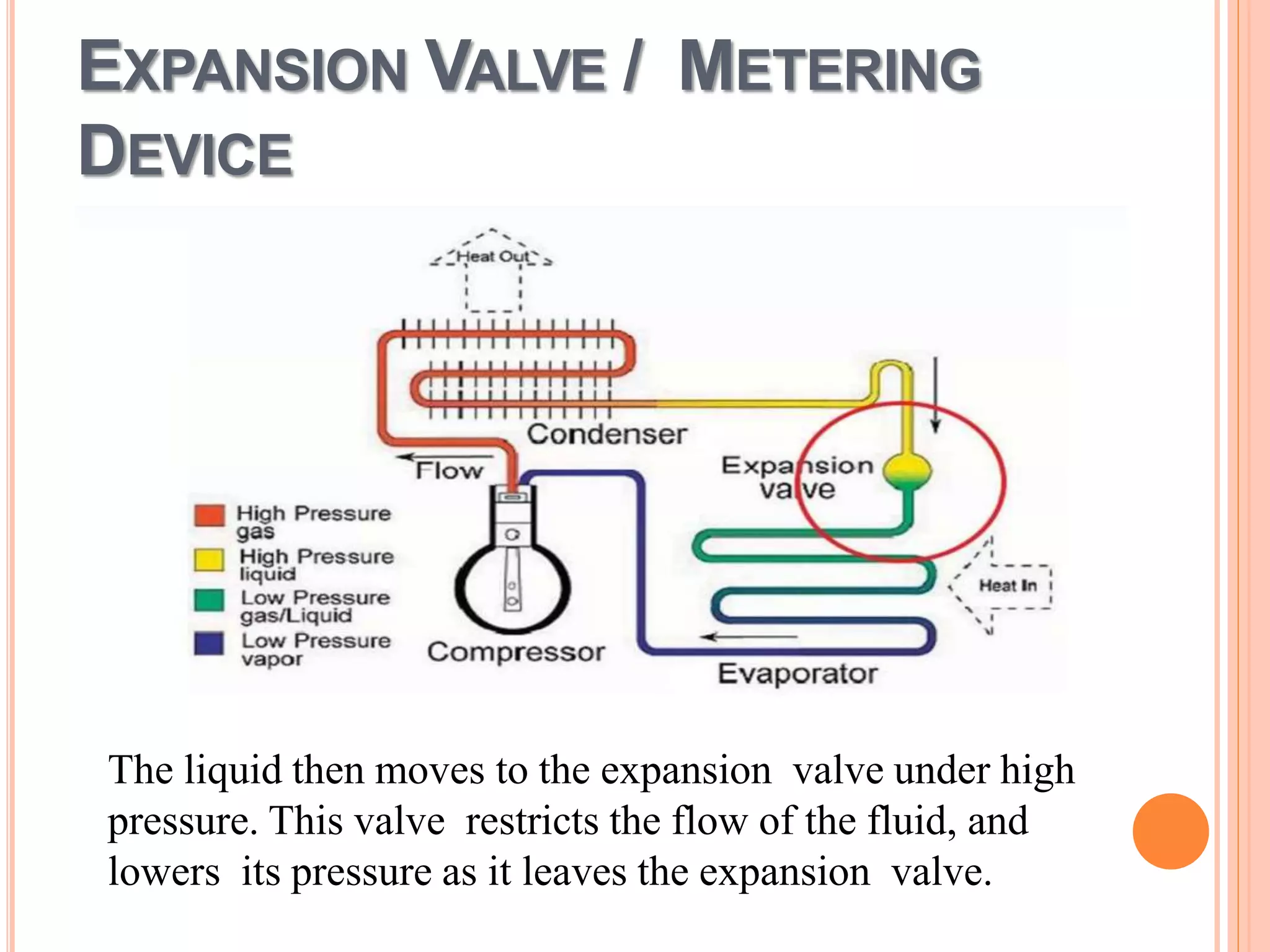

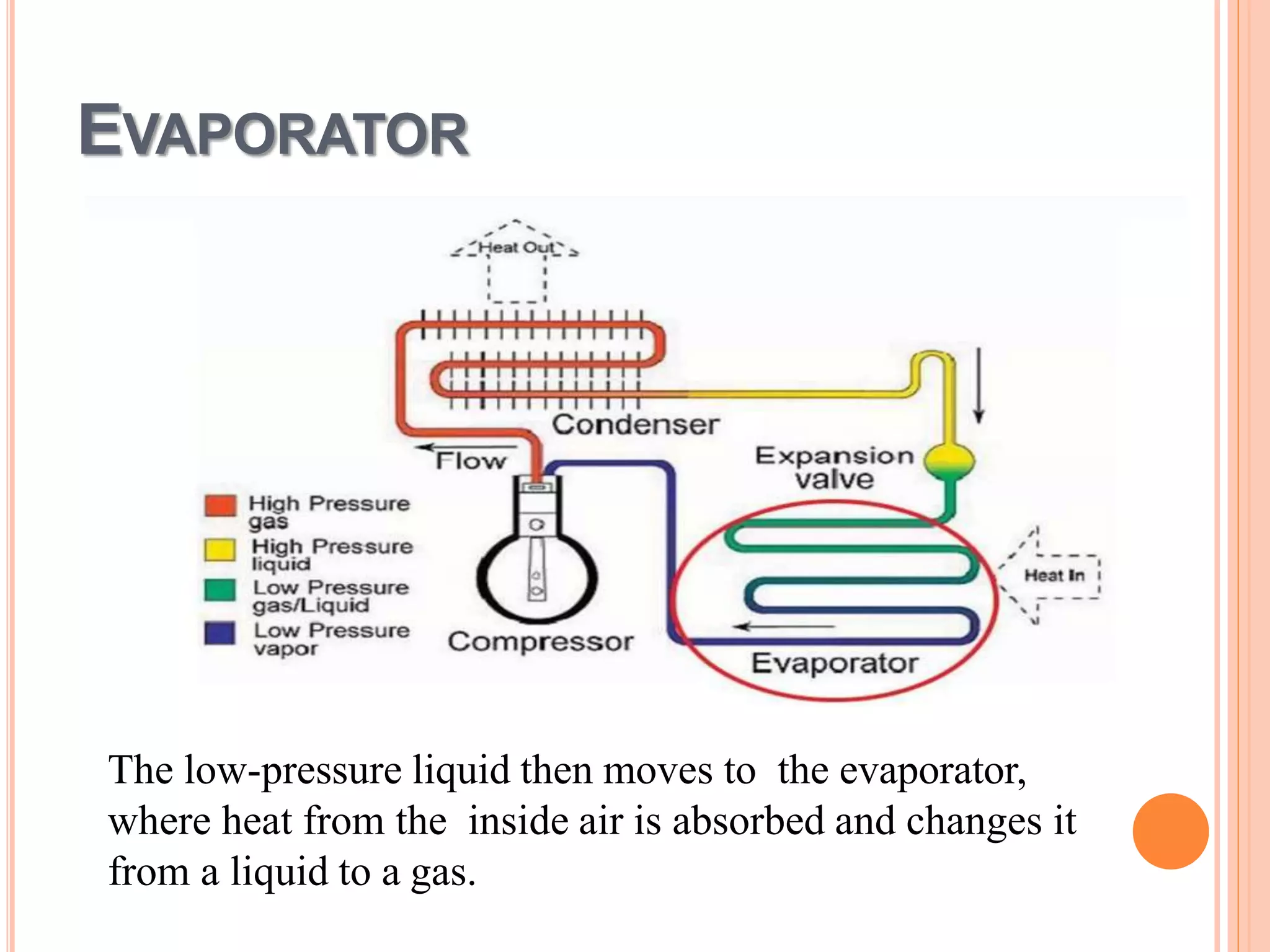

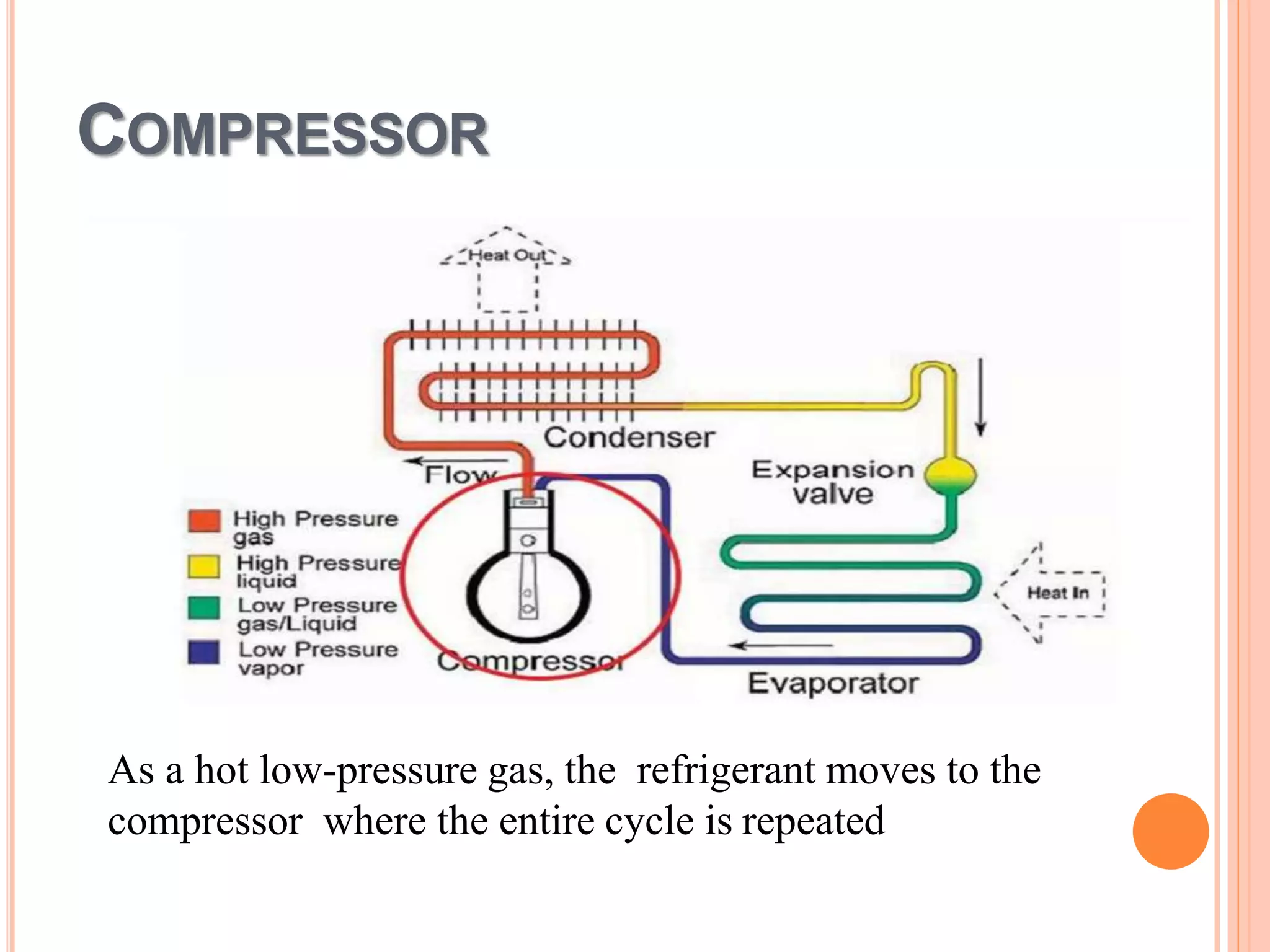

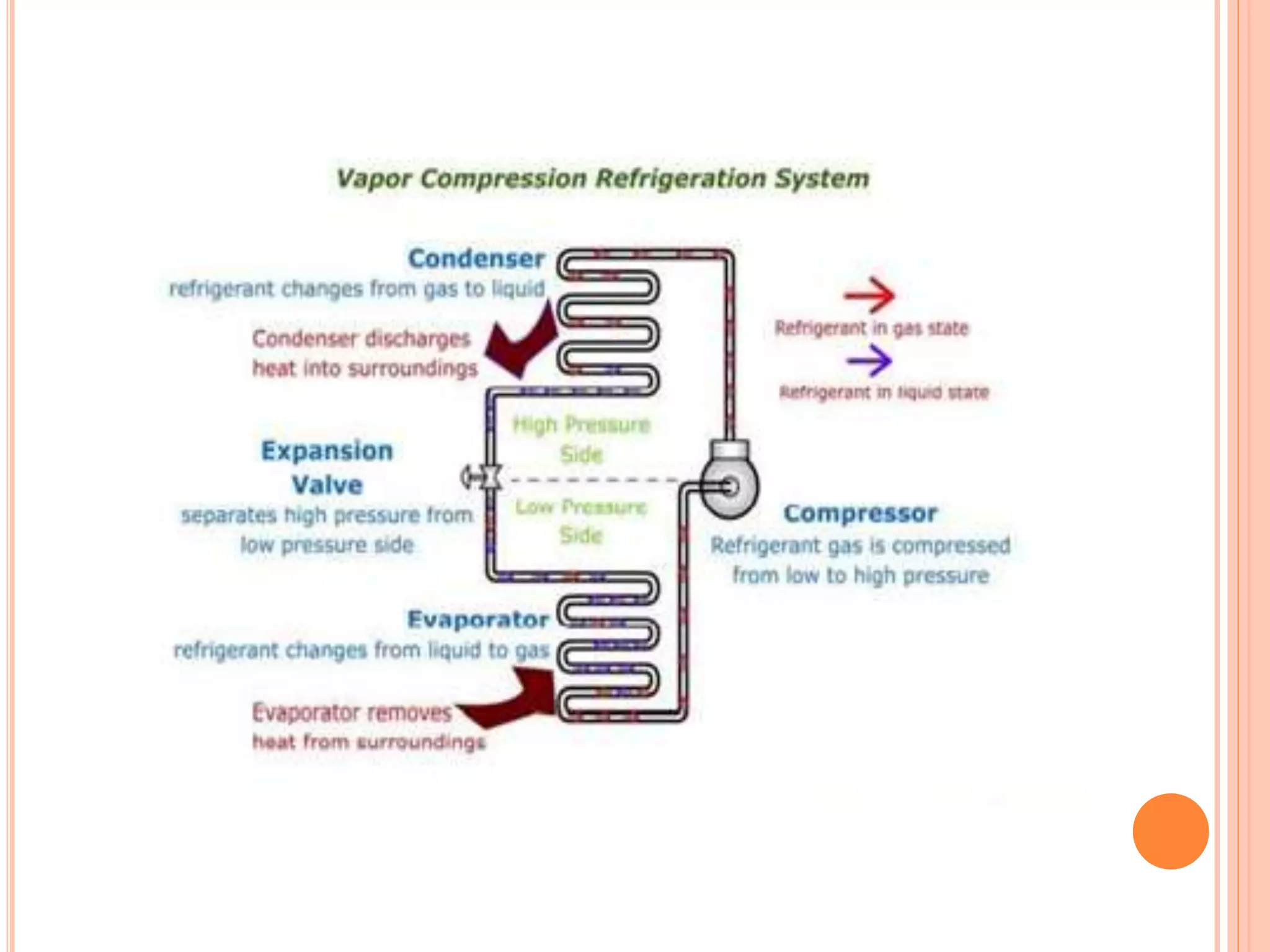

The document discusses the basic refrigeration cycle. It begins by introducing refrigeration as the transfer of heat from a lower to higher temperature region. The most common refrigeration cycle is the vapor compression cycle, where the refrigerant alternates between vaporization and condensation states and is compressed as a vapor. The basic processes of the refrigeration cycle are: (1) compression, (2) heat rejection during condensation, (3) expansion, and (4) heat absorption during evaporation. The cycle is repeated through the compressor. The coefficient of performance is used to measure efficiency. Selection of the right refrigerant depends on the specific application.