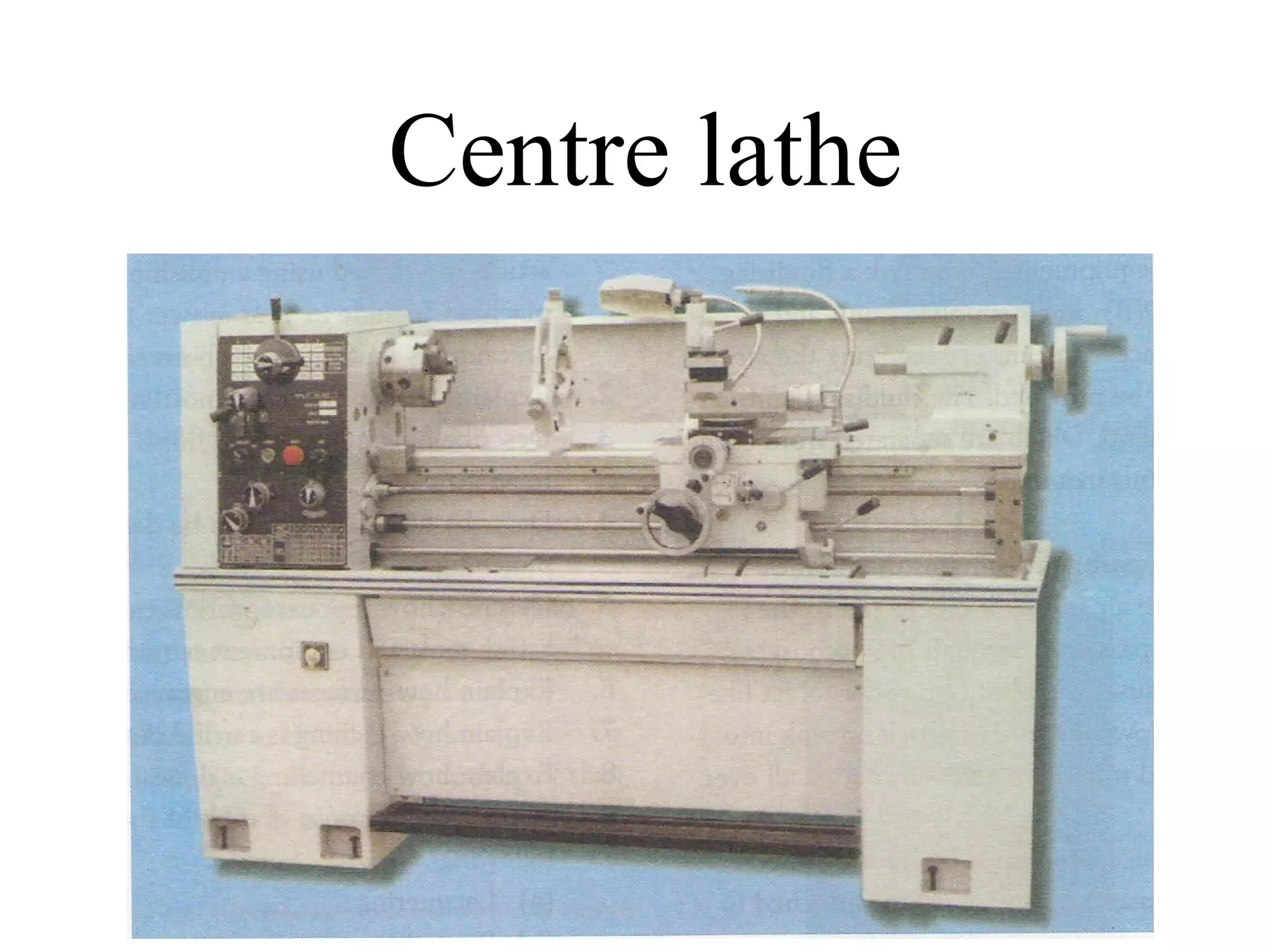

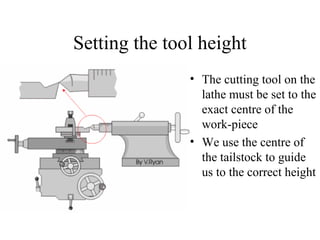

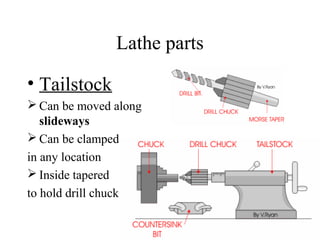

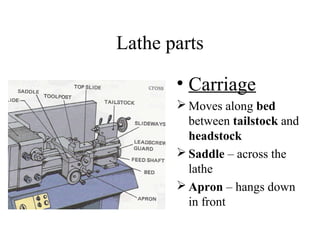

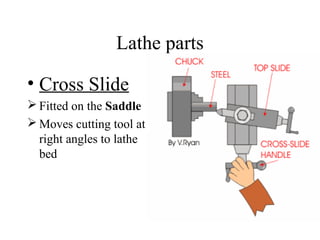

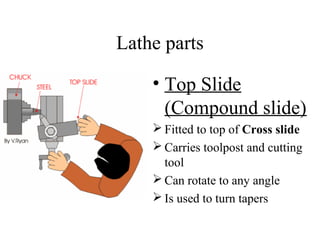

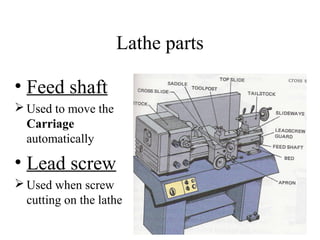

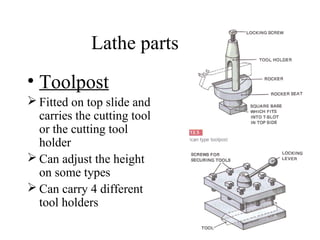

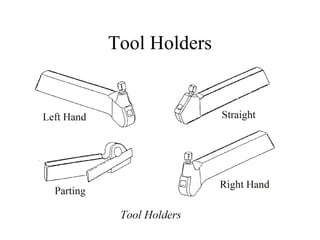

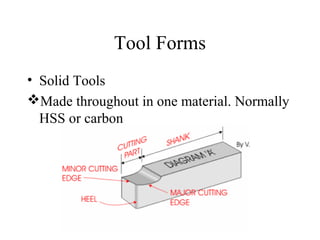

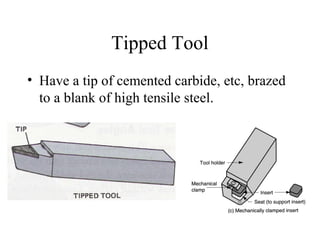

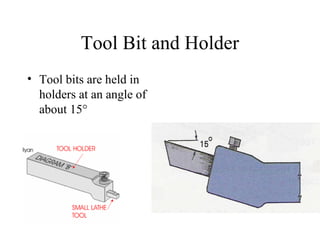

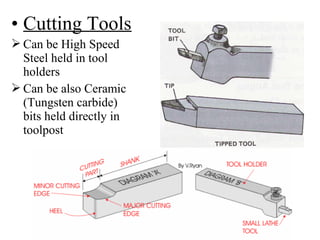

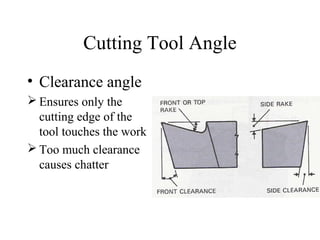

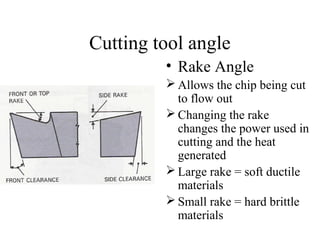

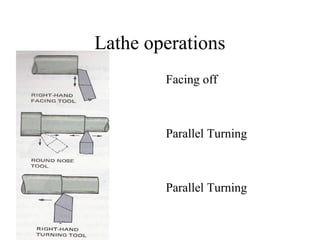

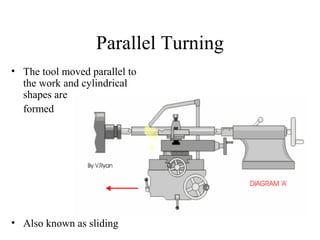

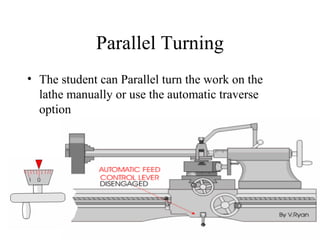

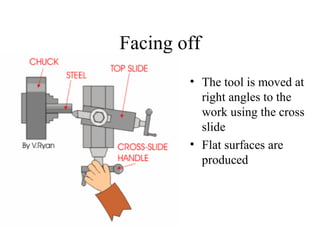

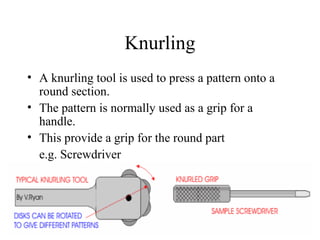

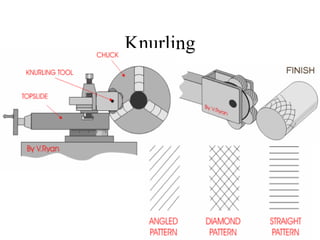

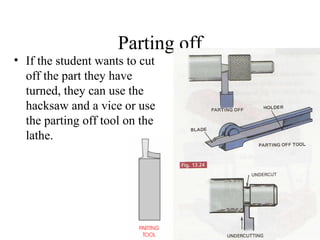

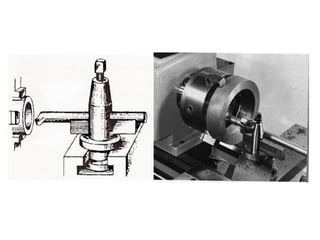

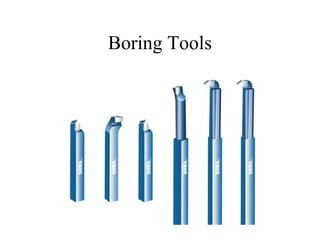

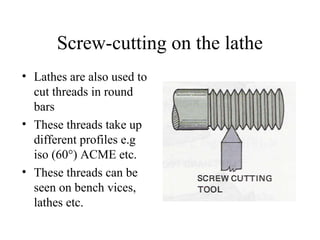

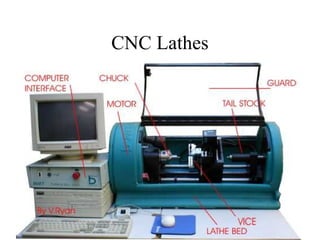

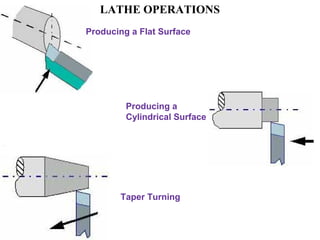

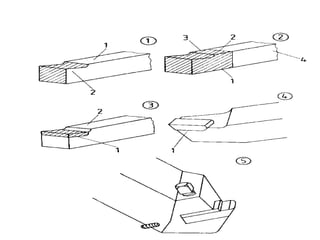

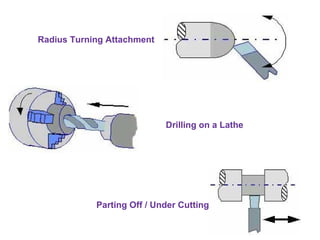

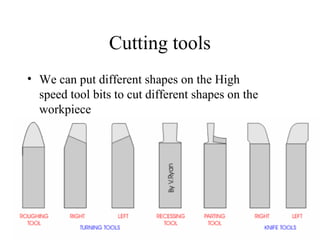

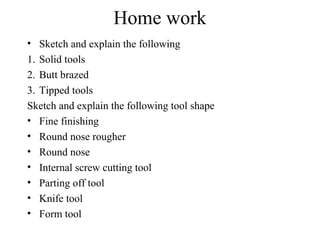

The document describes various parts of a lathe machine and cutting tools used. It explains how to set the tool height and lists main lathe parts like the tailstock, carriage, cross slide, top slide, feed shaft, lead screw, toolpost and tool holders. It discusses different cutting tool materials from carbon steel and high speed steel to carbides and diamond. It also outlines common lathe operations like parallel turning, facing, knurling and parting off. CNC lathes are mentioned as more efficient for mass production. Tool shapes depend on the operation, material and desired finish. Homework involves sketching and explaining solid, butt-brazed and tipped tools as well as specific tool shapes.