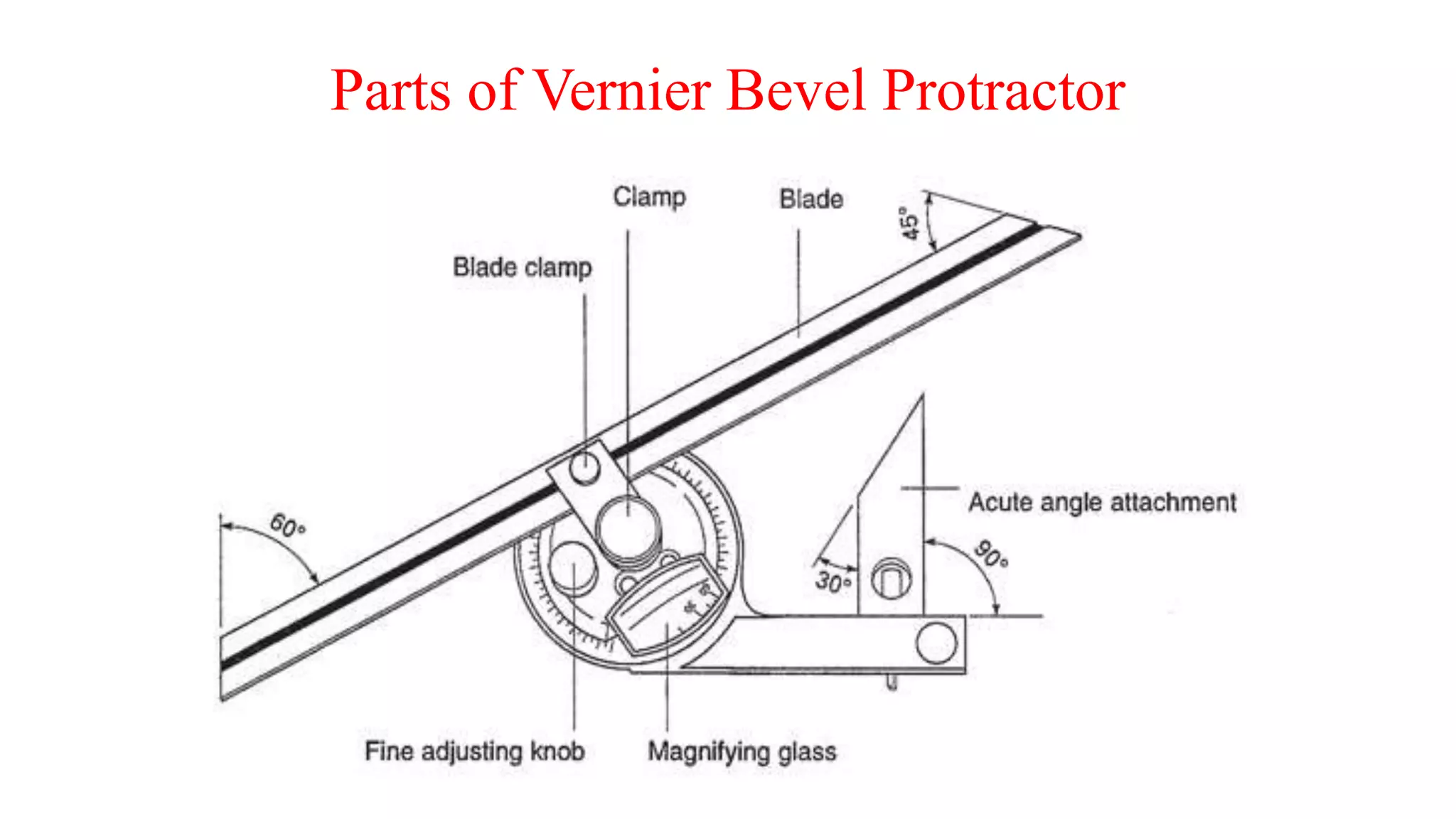

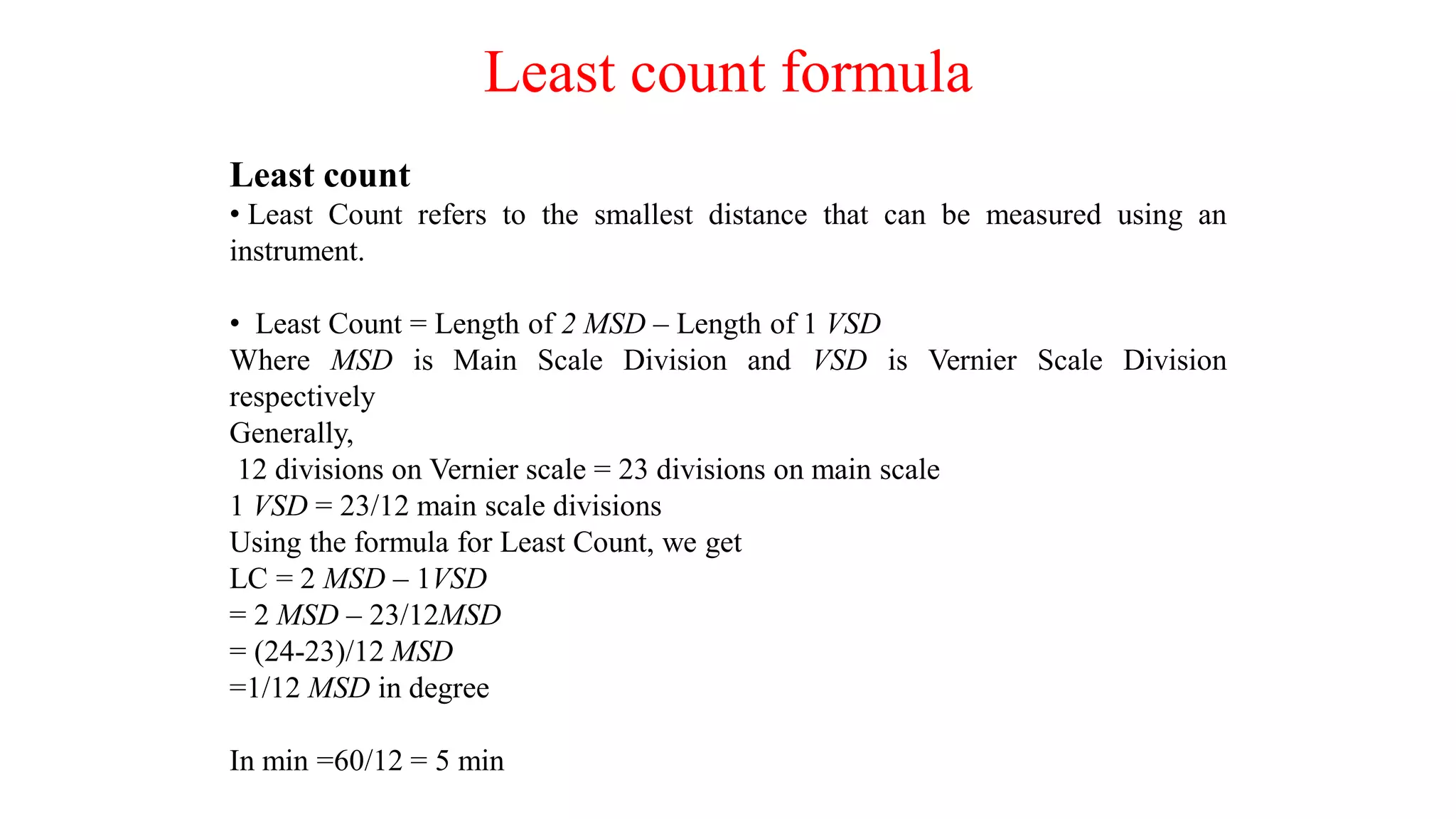

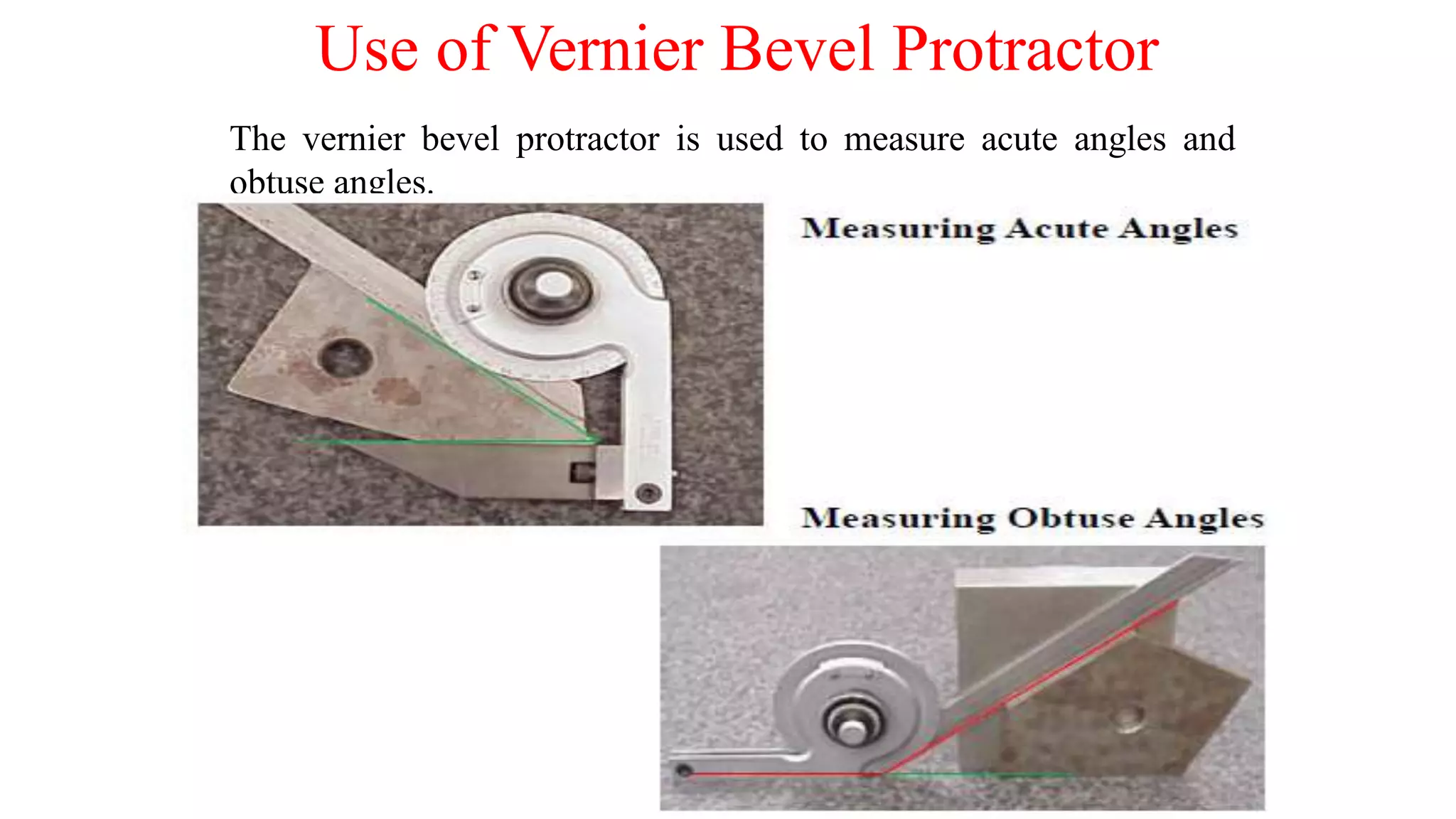

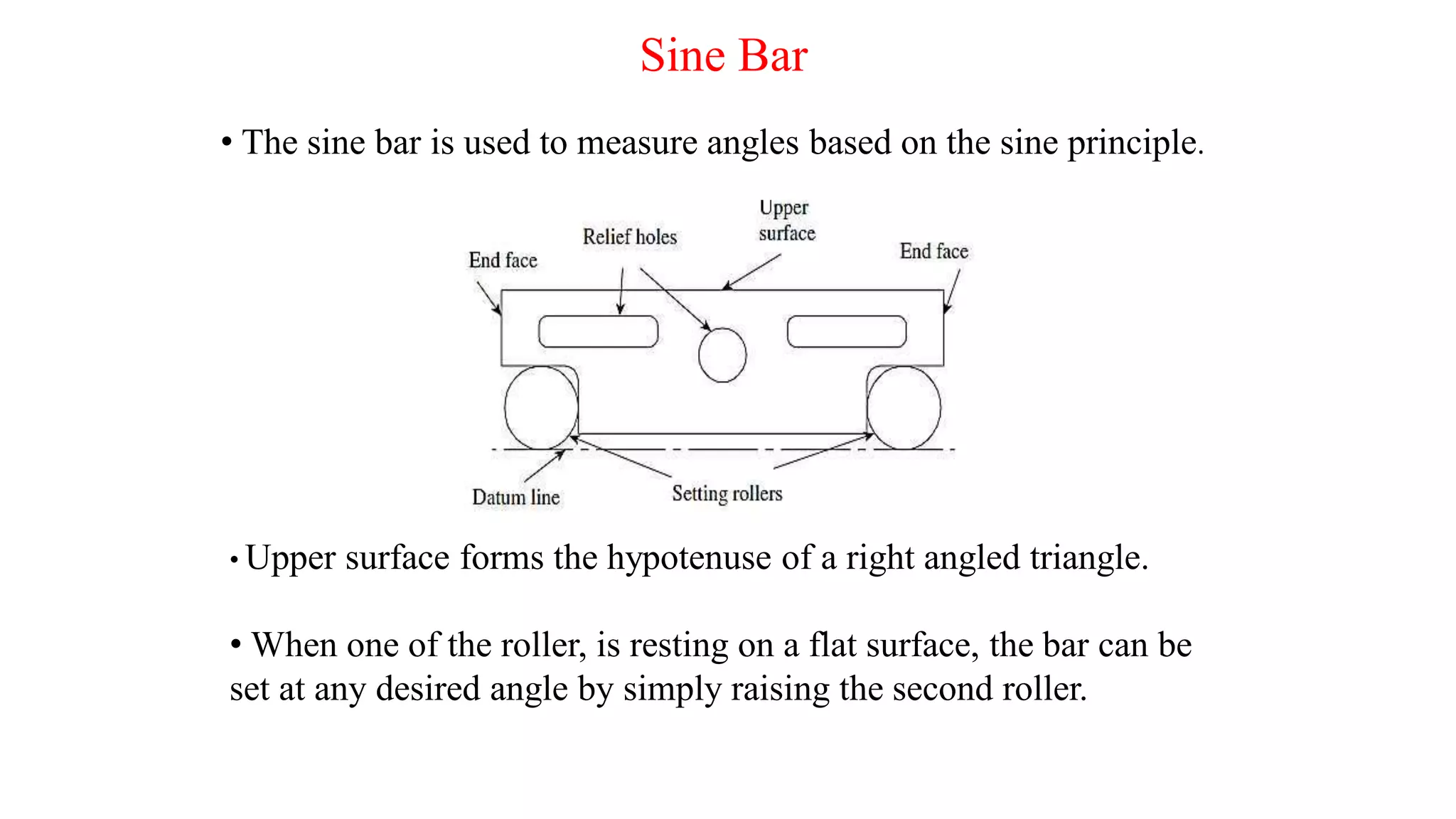

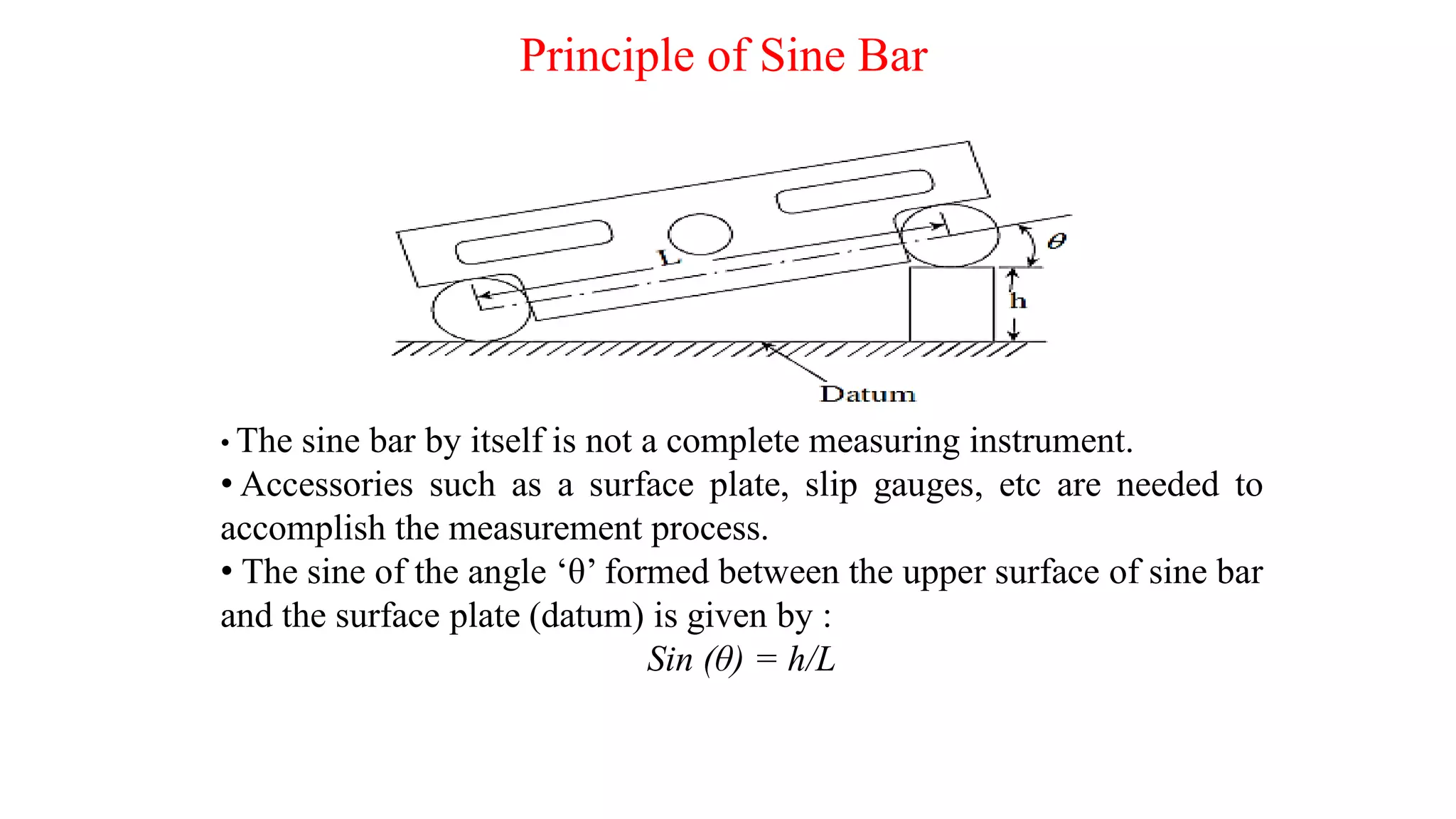

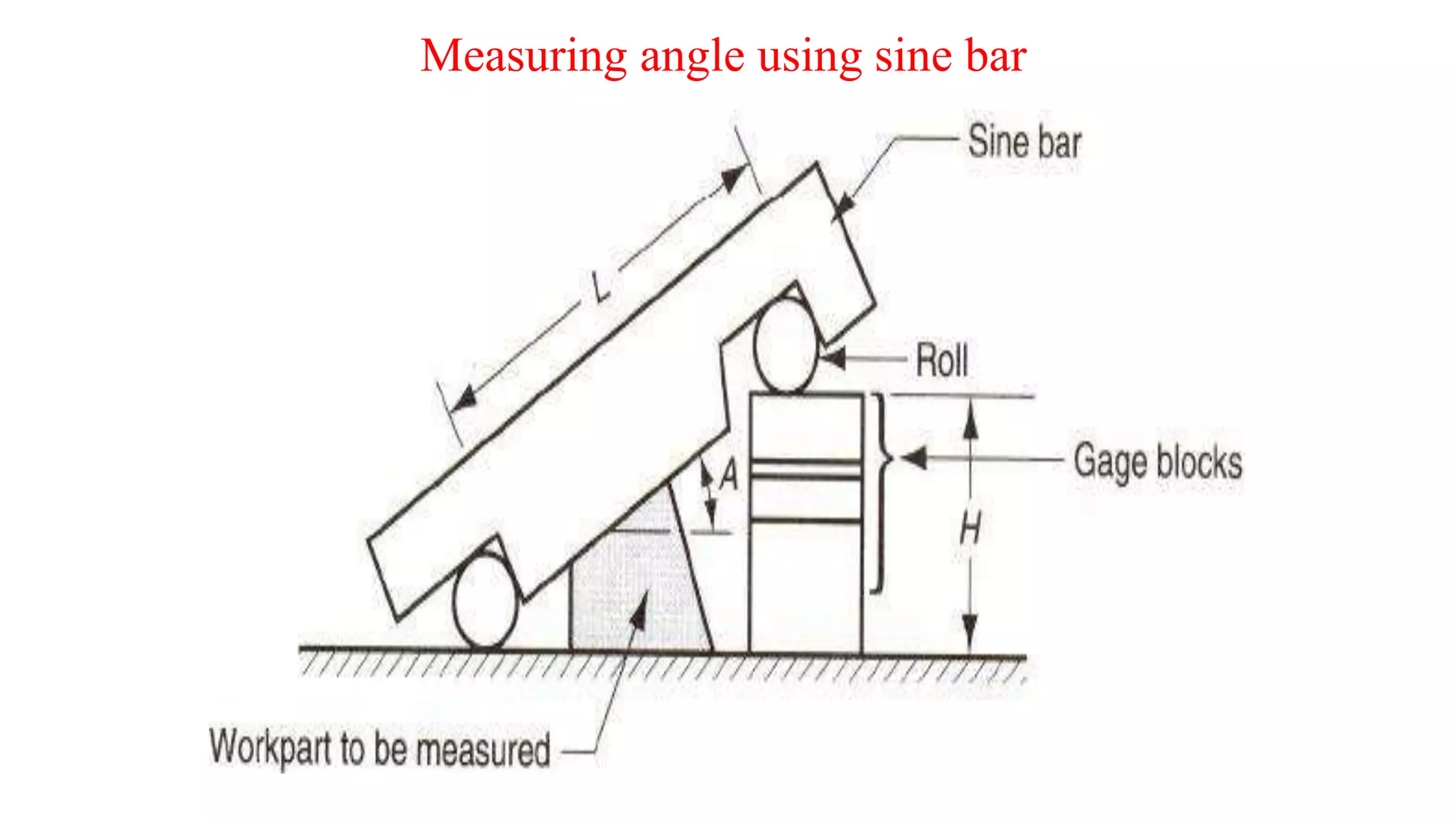

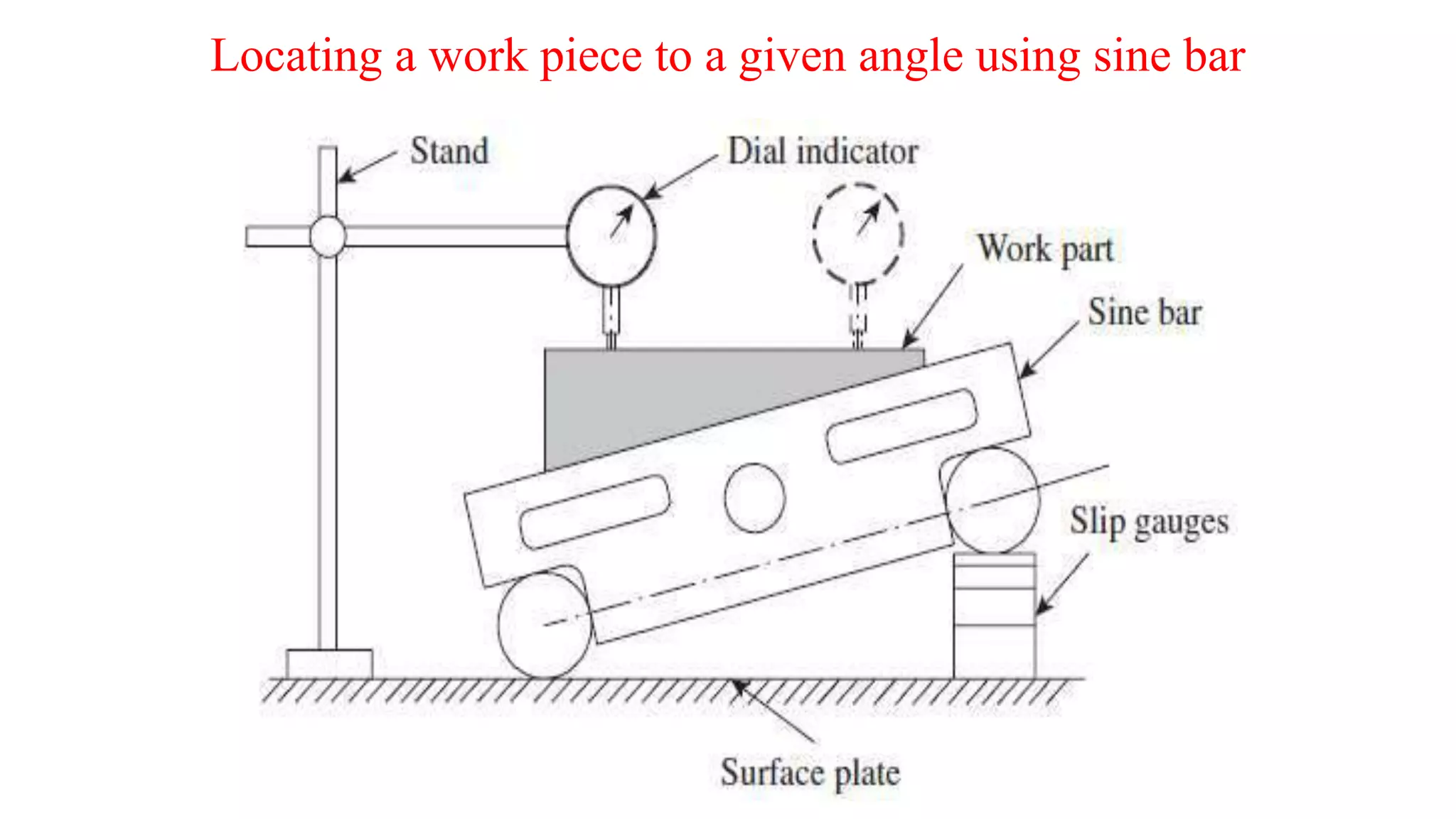

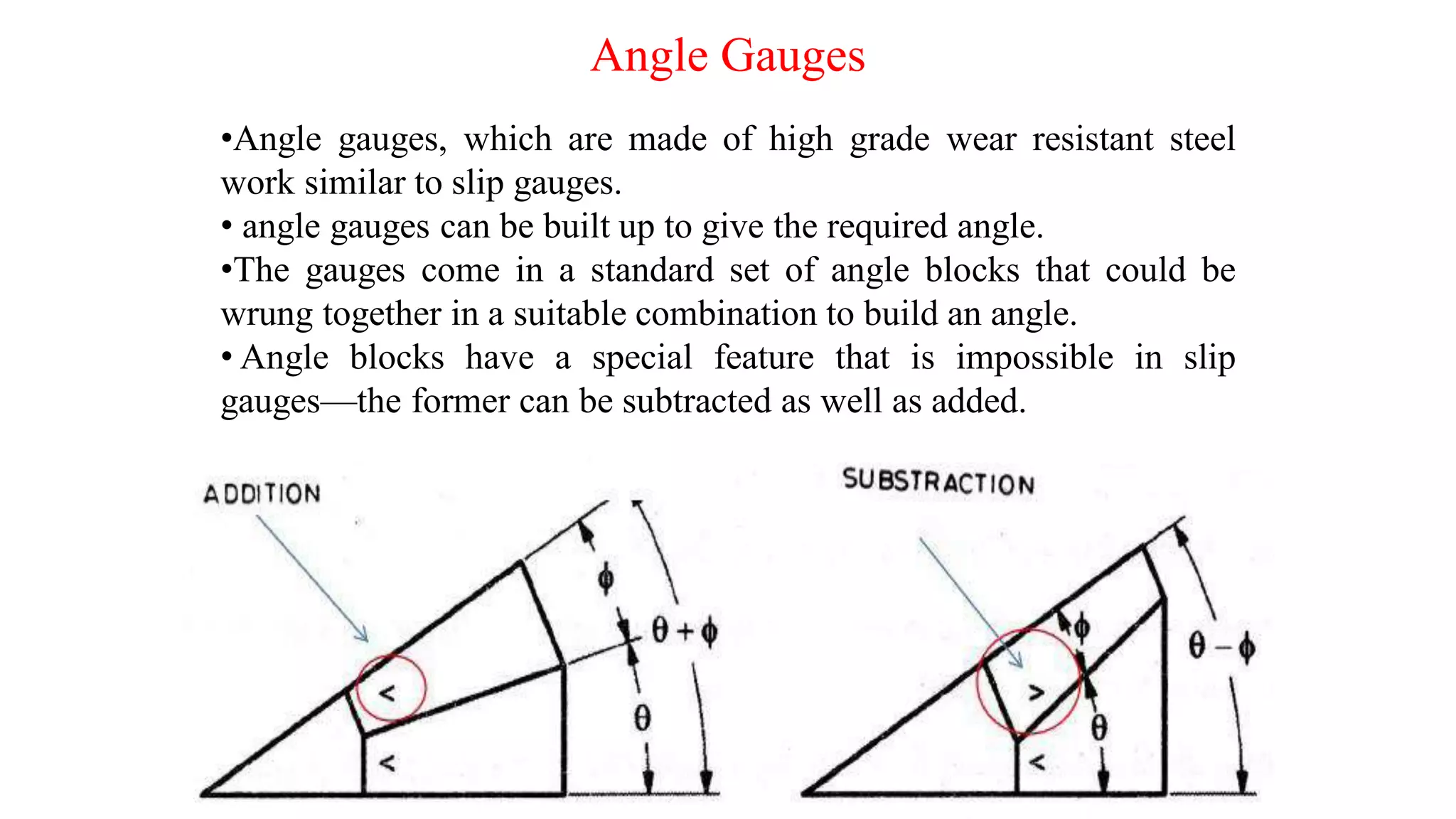

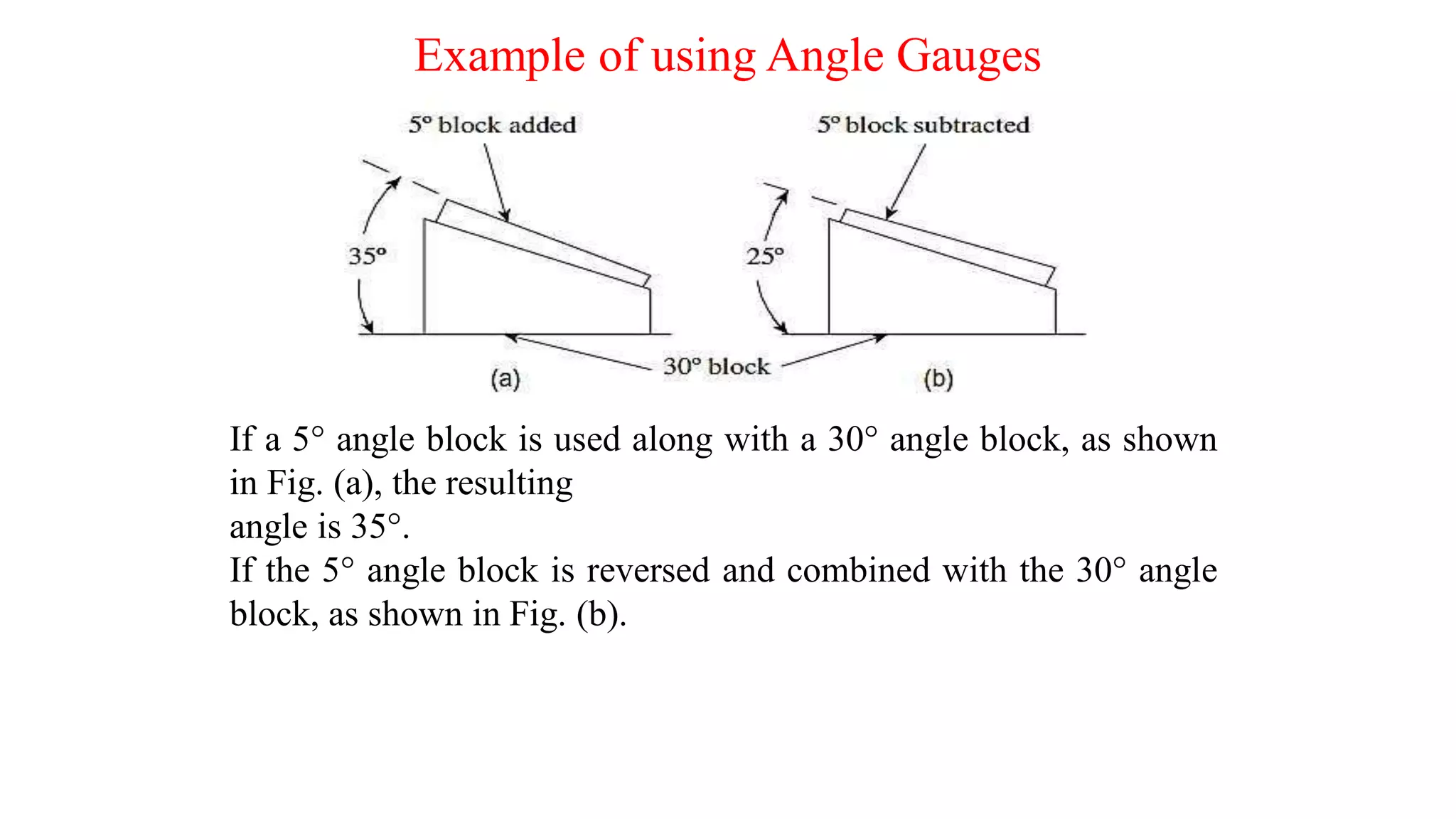

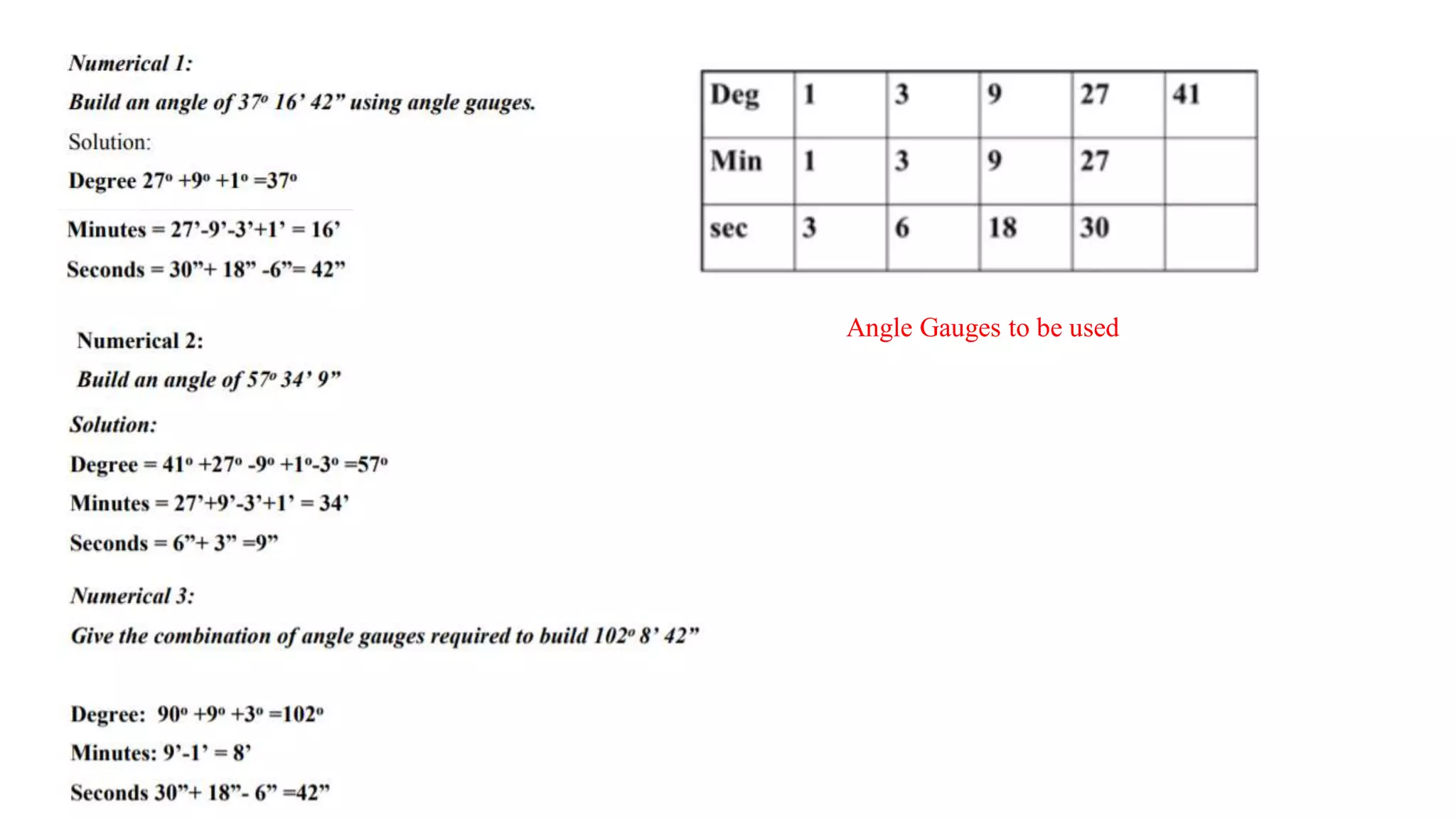

This document provides information on various tools used for angular measurement in engineering. It discusses simple protractors, vernier bevel protractors, sine bars, and angle gauges. The vernier bevel protractor allows measuring angles to the nearest minute using a vernier scale. It has a stock, dial, blade, and locking screws. A sine bar measures angles based on trigonometric relationships between the bar length and height of slip gauges. It requires accessories and is limited to angles above 45 degrees. Angle gauges can be combined in different configurations to measure angles from 0 to 90 degrees and minutes.