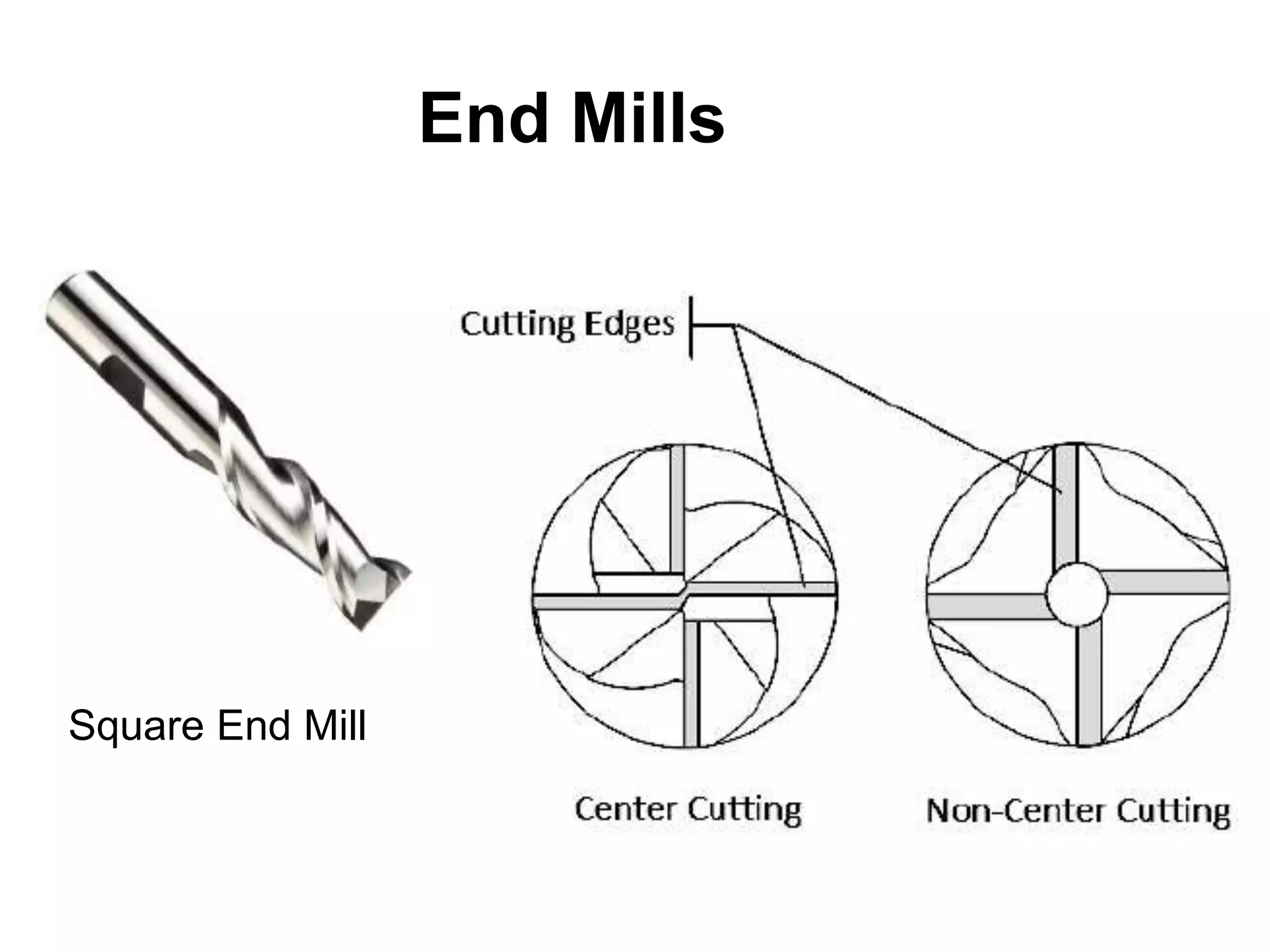

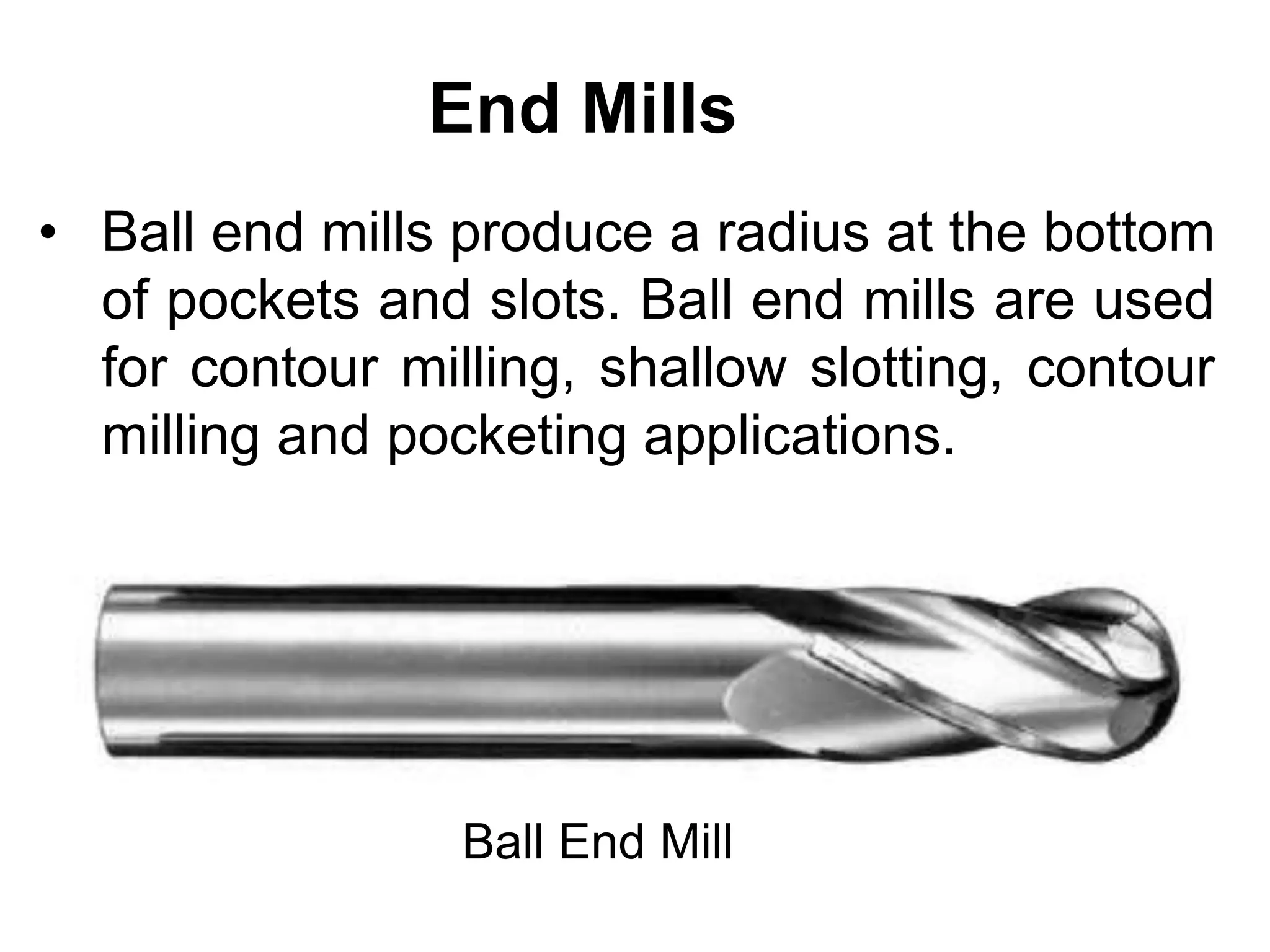

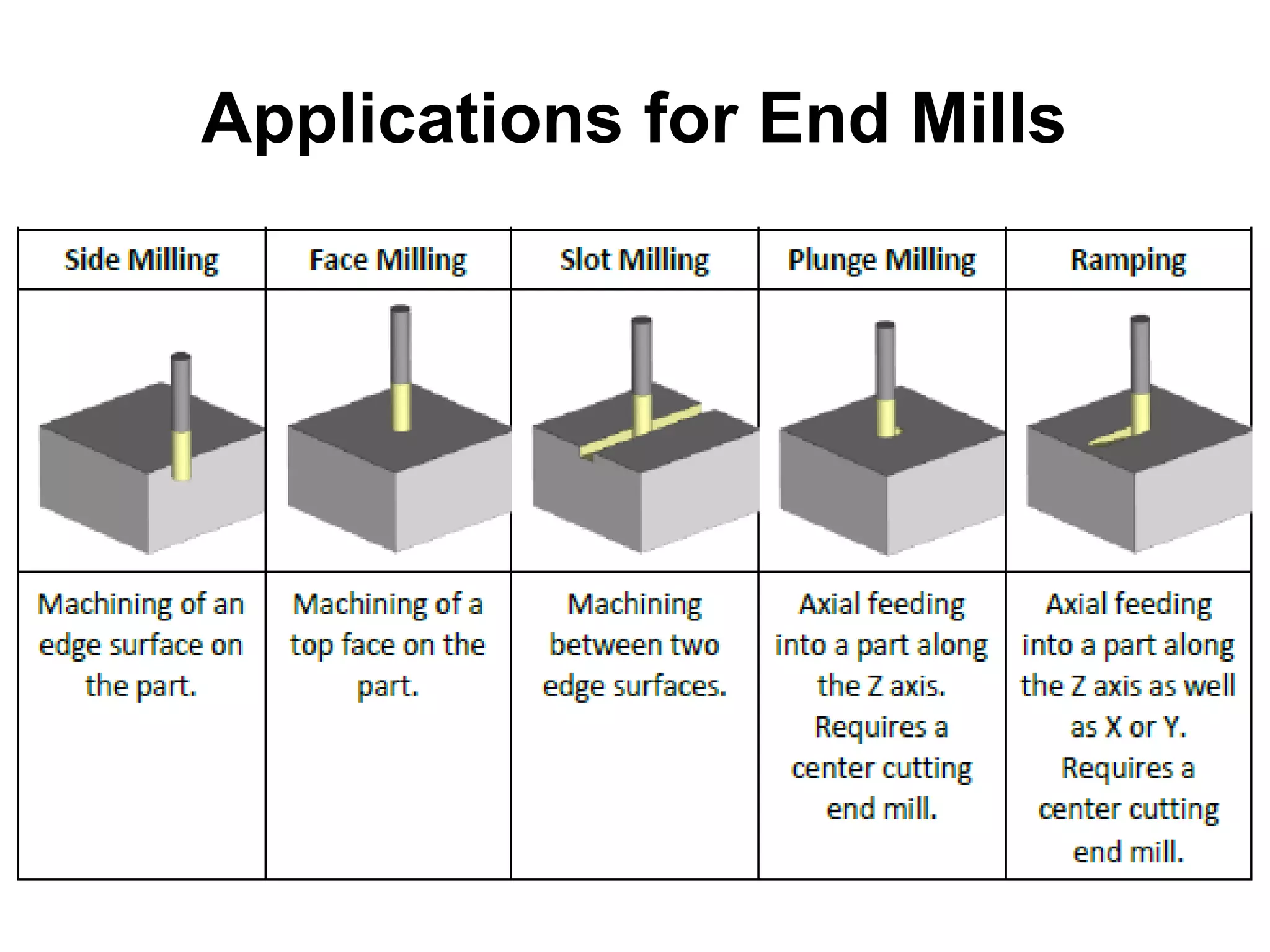

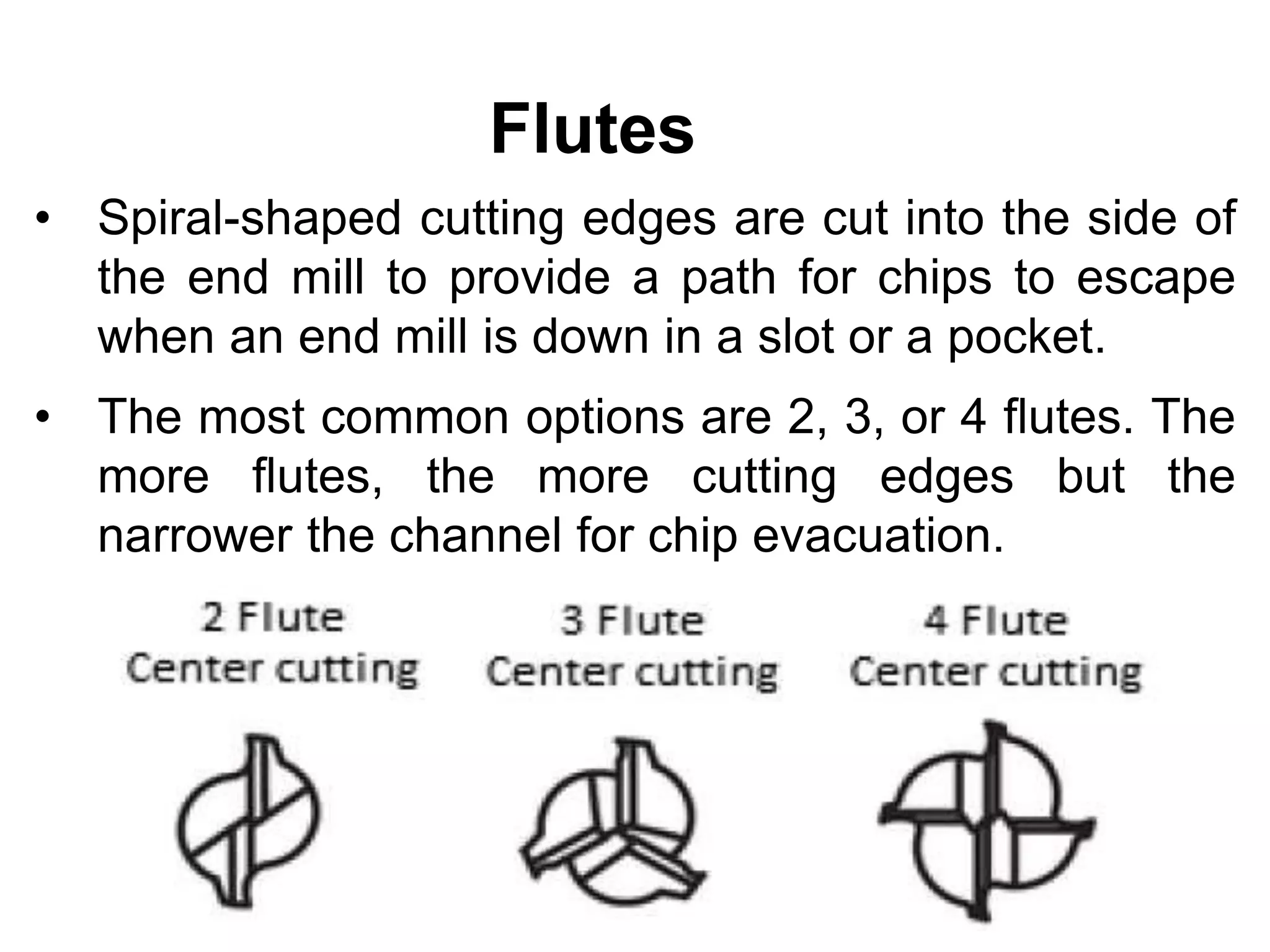

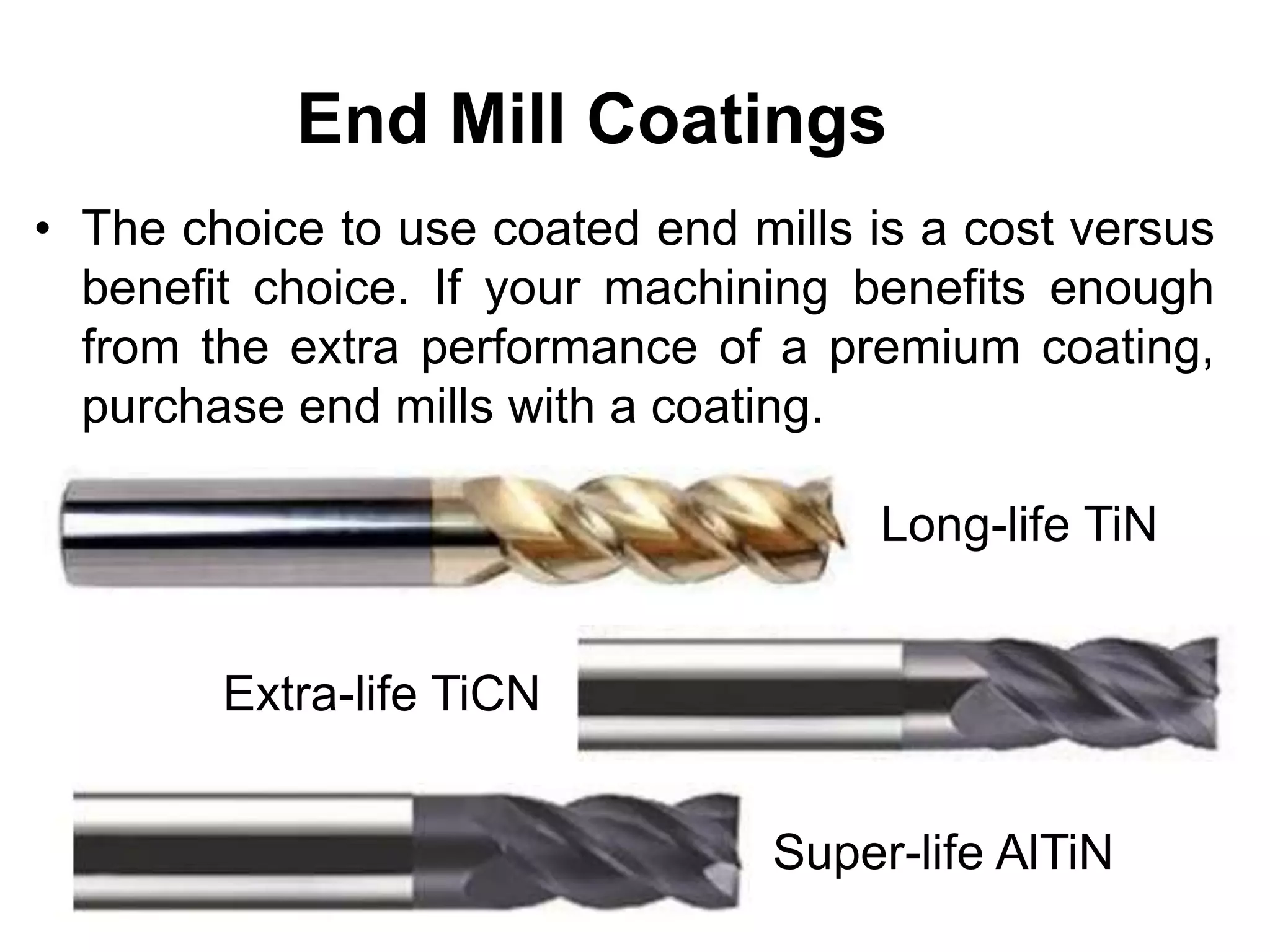

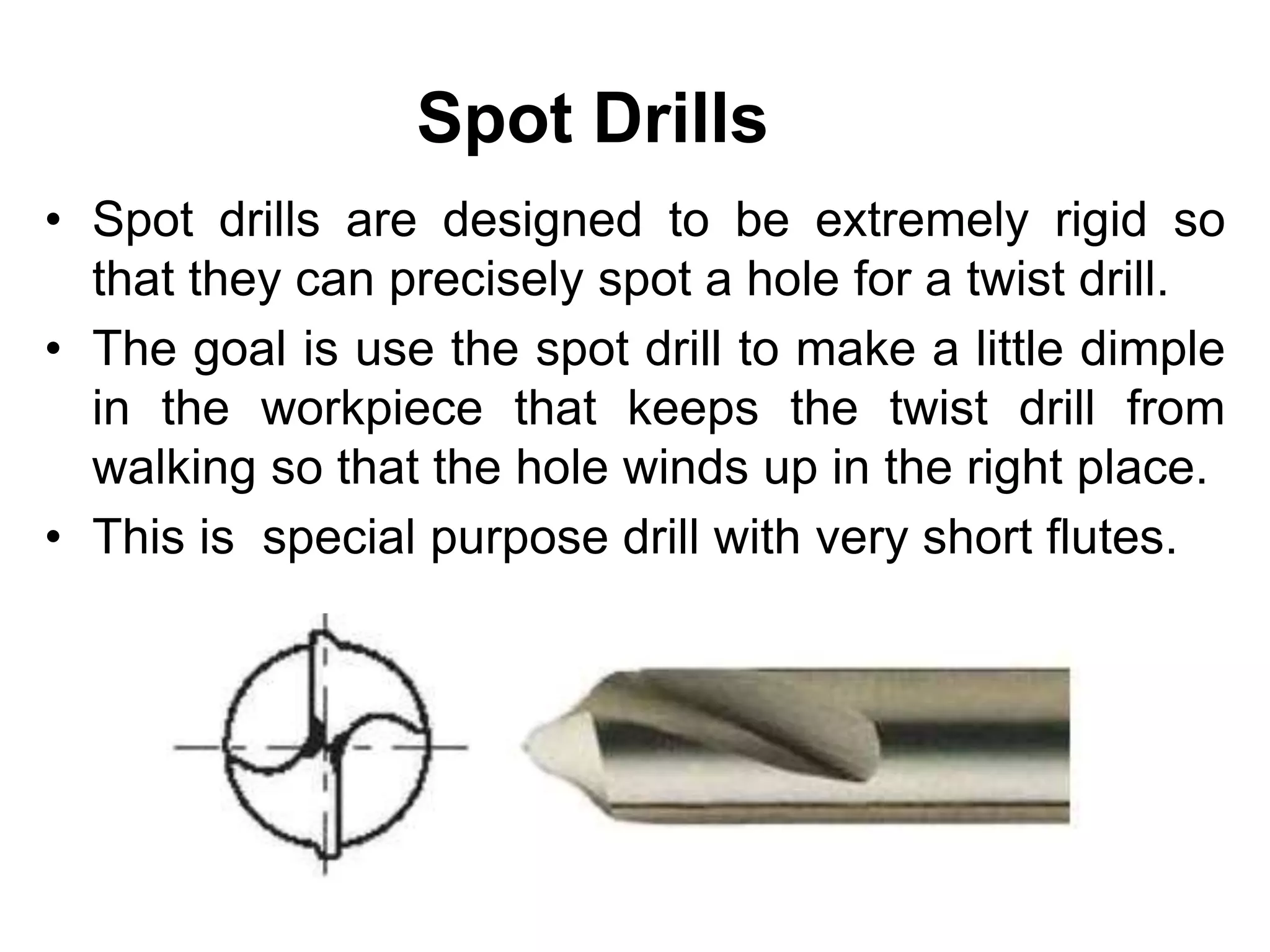

The document discusses common tools used in CNC milling, including end mills, face mills, drills, taps, and reamers. It describes the different types of each tool as well as factors to consider like material, coatings, flutes, and holders. End mills are the most versatile cutting tools and come in various styles for different milling applications. Tool coatings can increase hardness and wear resistance for better performance. Proper tool holders are also important for secure and accurate mounting of cutters.