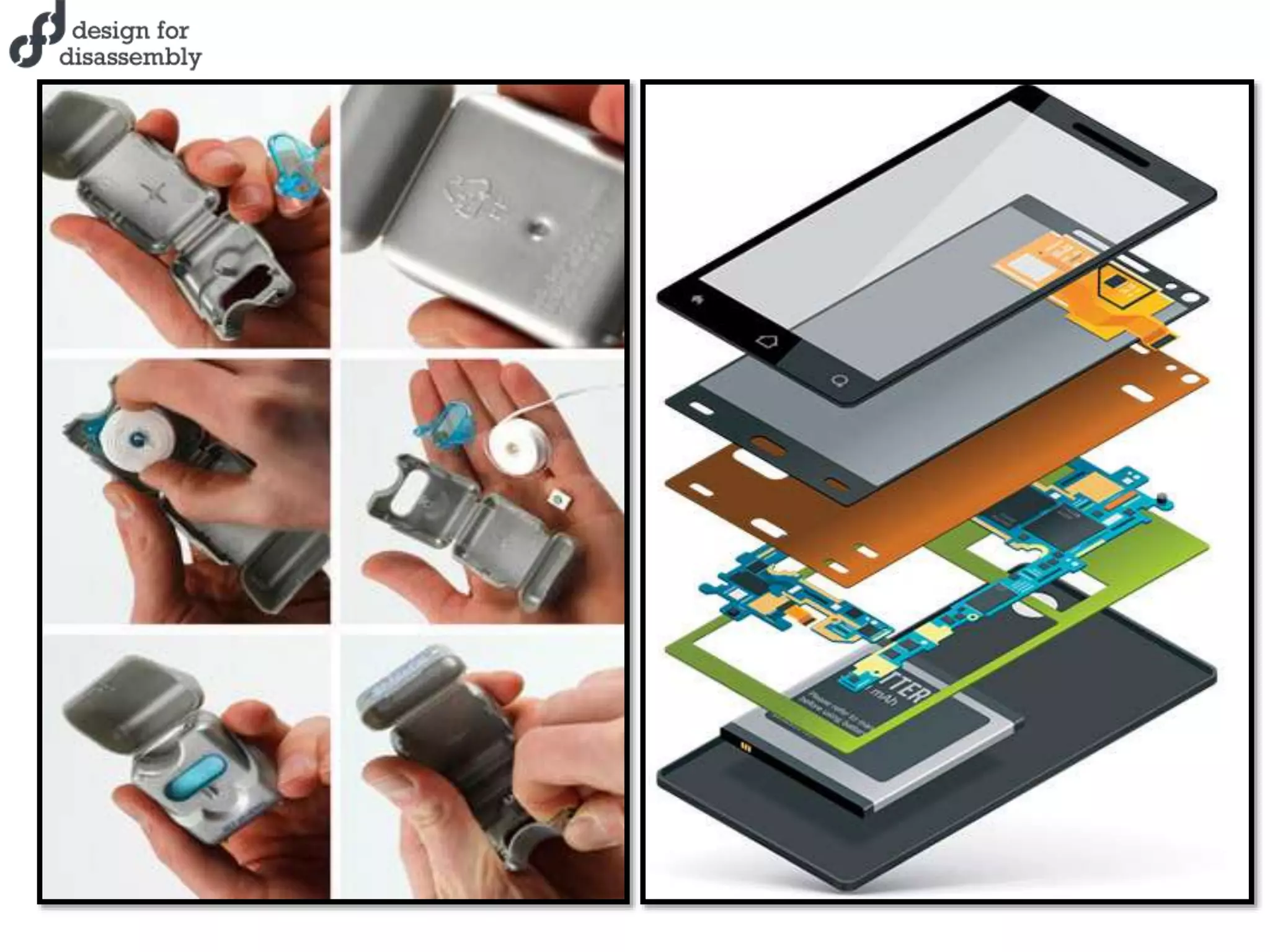

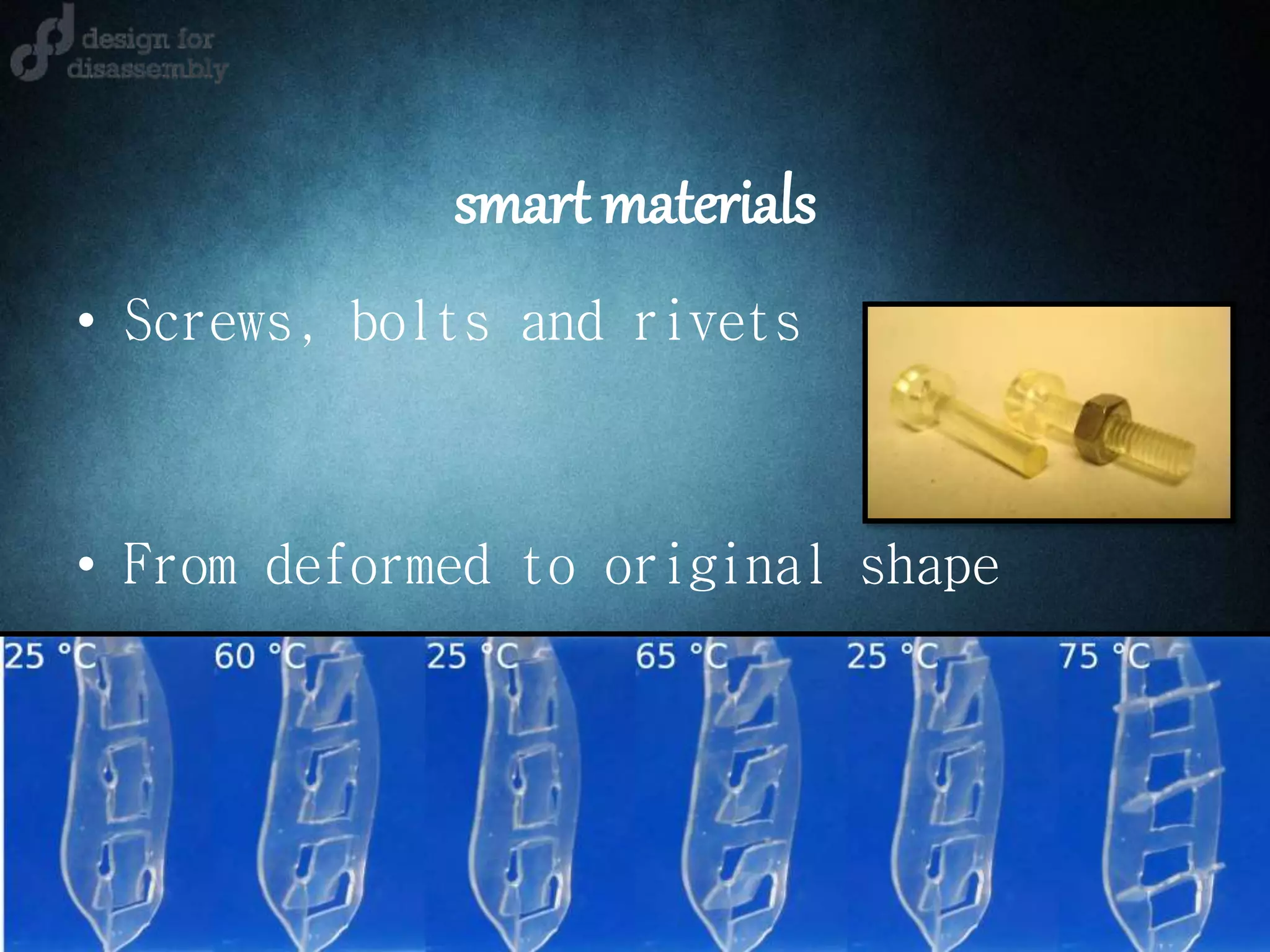

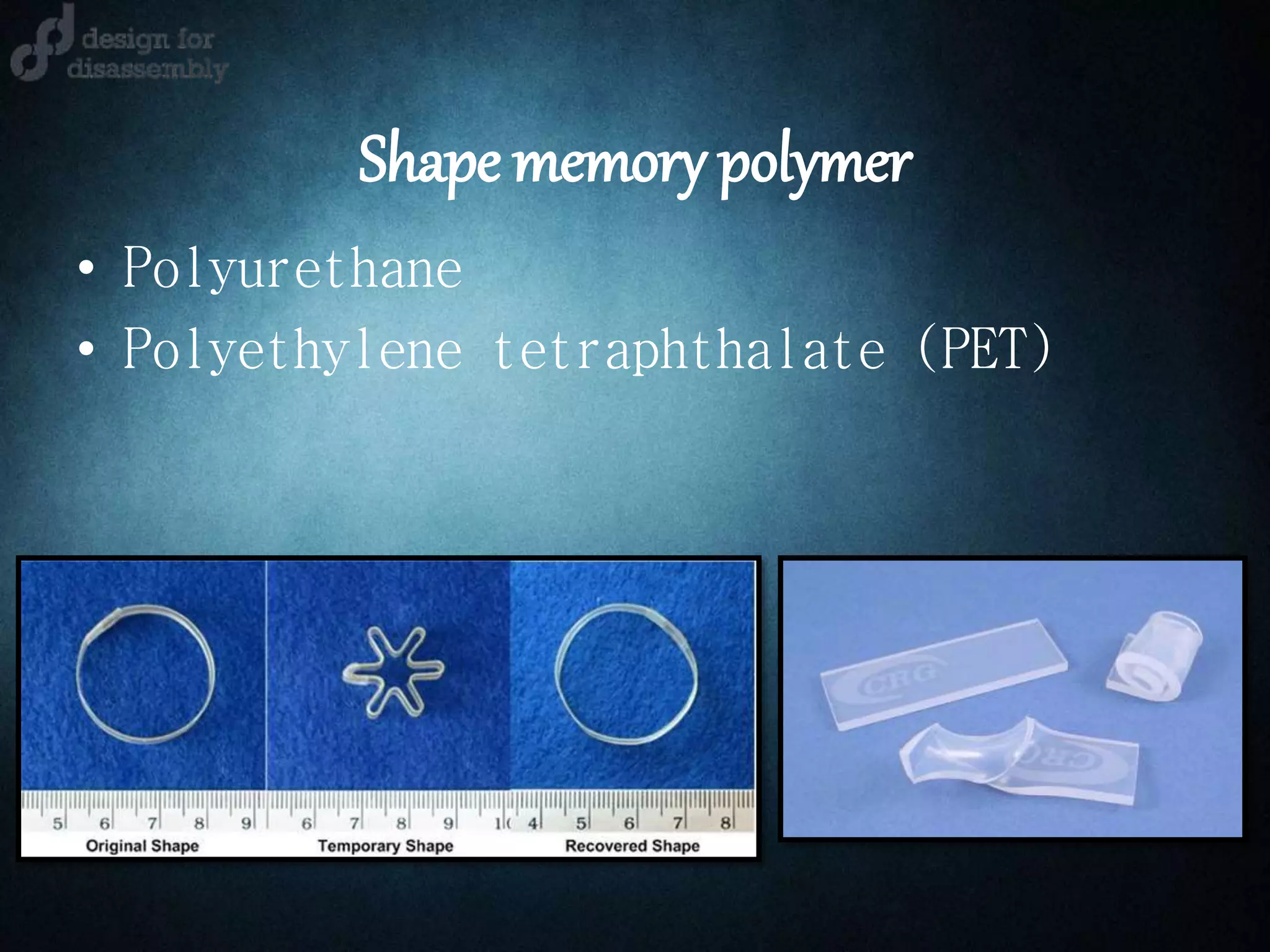

This document discusses design for disassembly (DFD), which involves designing products to be easily taken apart at the end of their life so components can be reused or recycled. DFD is part of design for the environment and sustainable product design. It reduces production costs and increases technical efficiency and flexibility. Active disassembly uses smart materials like shape memory polymers and alloys to allow components to self-disassemble through stimuli like heat. Principles for DFD include selecting recyclable materials, using standardized fasteners, and avoiding permanent fixes. DFD benefits the environment by facilitating recycling and reuse.