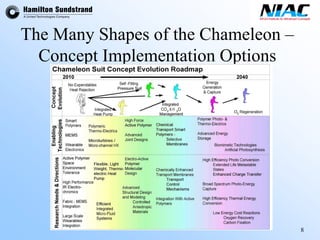

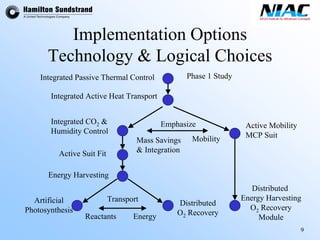

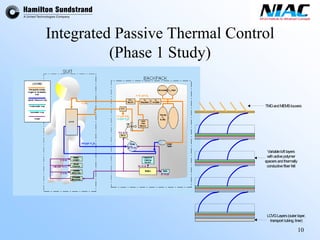

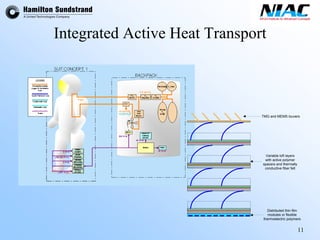

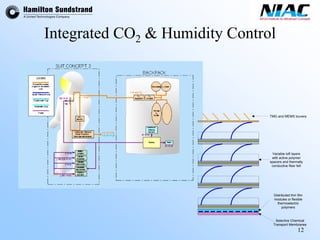

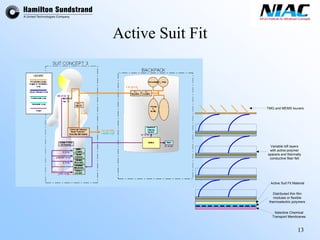

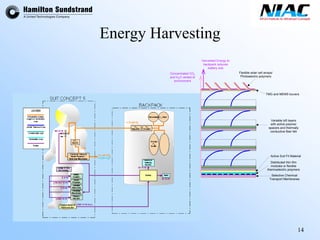

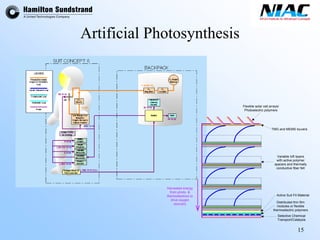

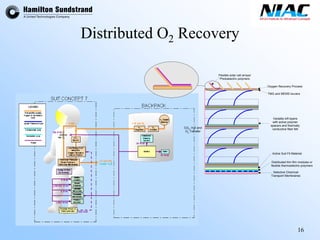

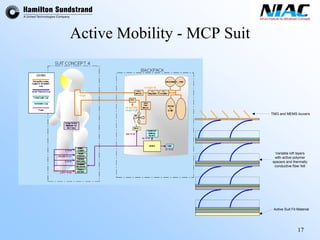

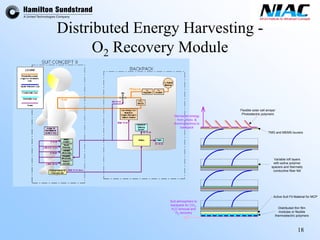

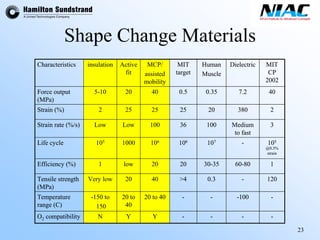

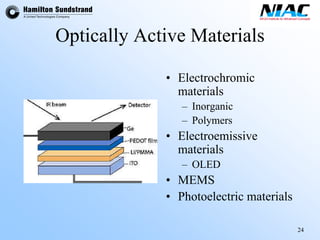

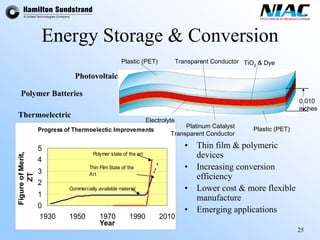

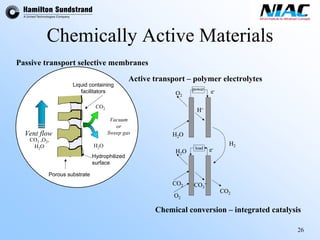

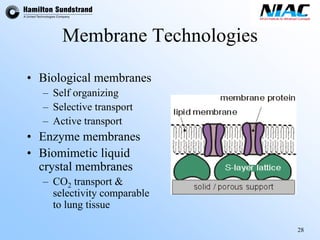

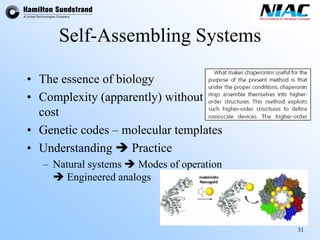

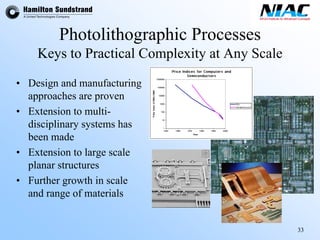

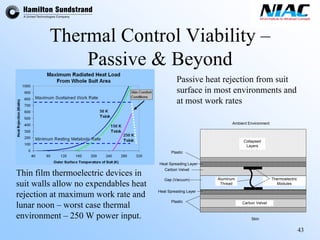

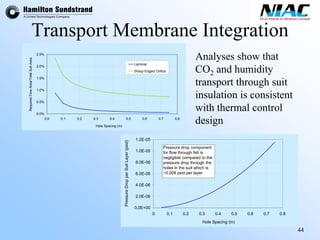

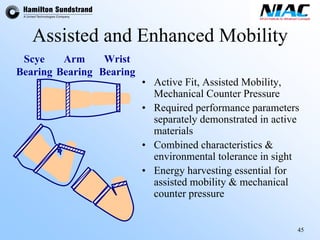

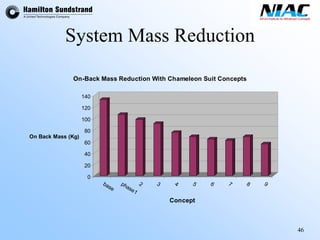

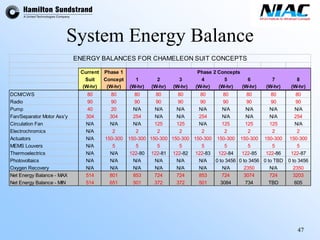

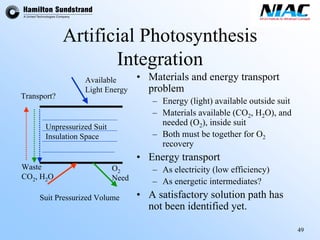

The document discusses the concept of a "Chameleon Suit" that aims to revolutionize extra-vehicular activity (EVA) systems through an integrated, multi-functional design approach. It outlines some of the key challenges with current EVA systems and opportunities emerging technologies provide to address issues like mobility, thermal control, life support and energy needs. The concept integrates functions like thermal regulation, gas transport and power generation directly into the suit material through the use of advanced materials like conductive polymers, shape memory alloys and thin film devices. While challenges remain around issues like artificial photosynthesis integration, the document argues the required technologies are advancing and a fully-integrated, lightweight suit that improves upon current systems is achievable.