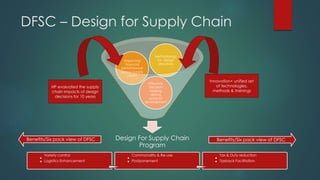

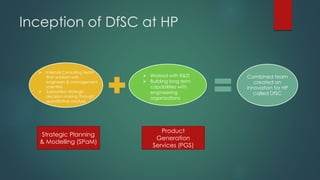

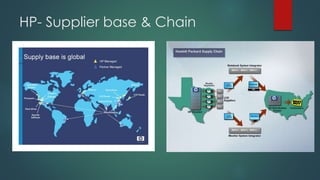

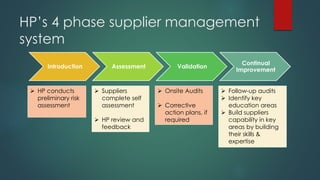

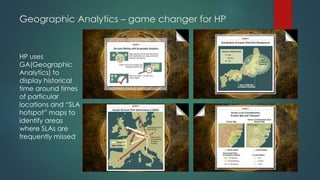

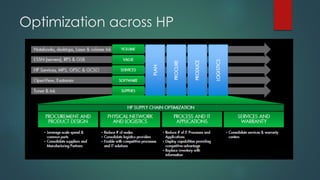

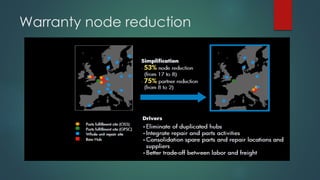

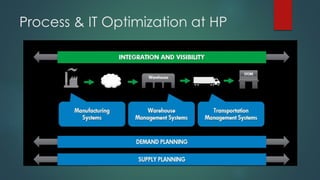

The document discusses supply chain initiatives at Hewlett-Packard. It describes HP's Design for Supply Chain program which aims to improve decision making and financial performance through evaluating supply chain impacts of design decisions. It also discusses HP's supplier management system, use of geographic analytics to improve service level agreements, efforts to standardize processes across regions through nearshoring and postponement strategies, optimization of warranty processing and business processes through technology and IT systems, and e-commerce initiatives to integrate ordering and inventory management with partners like FedEx.