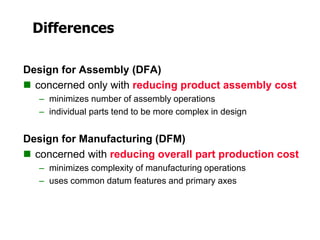

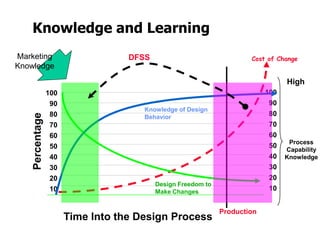

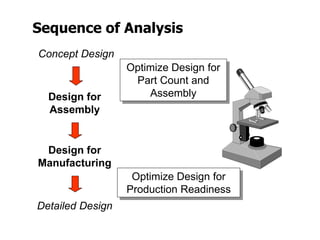

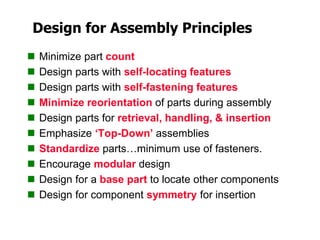

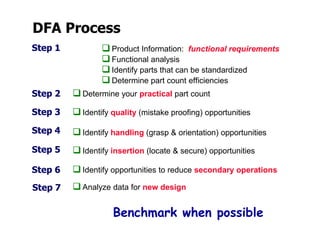

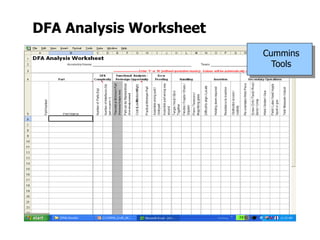

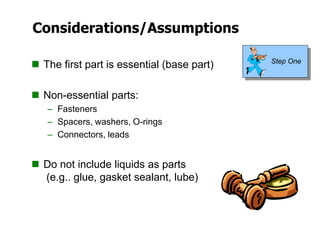

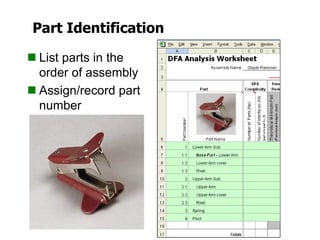

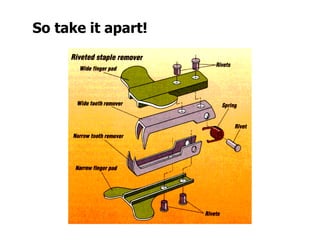

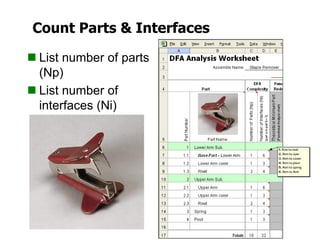

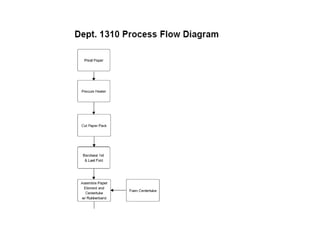

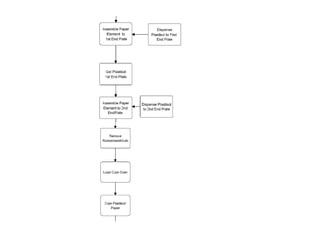

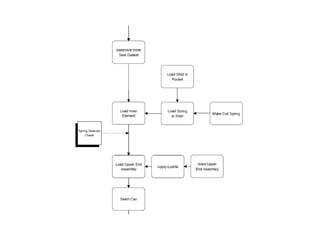

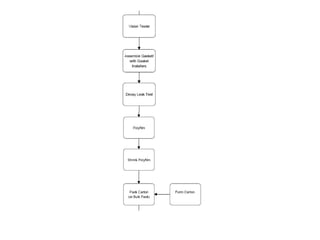

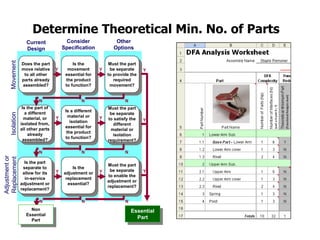

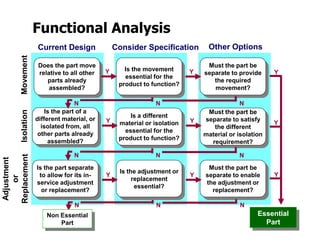

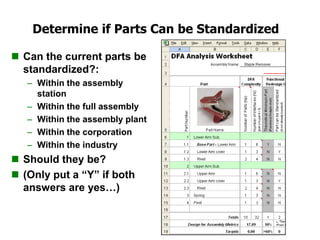

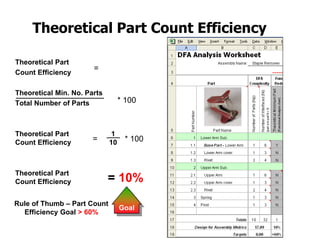

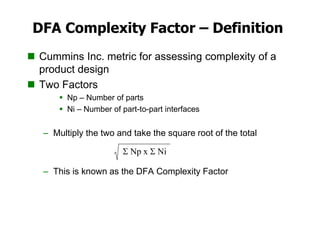

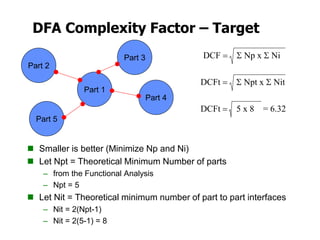

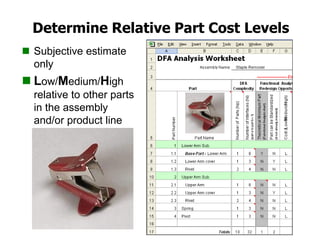

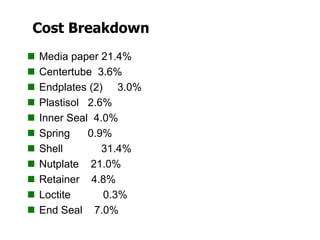

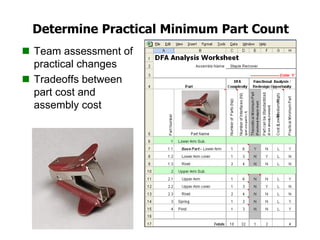

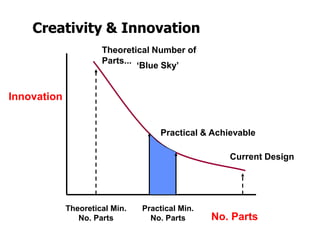

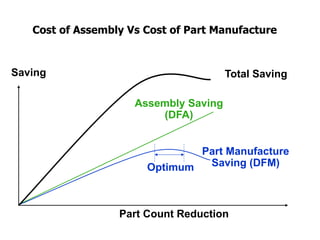

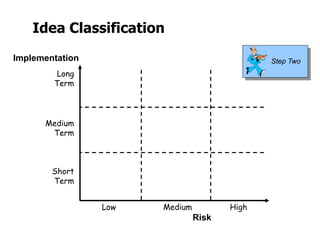

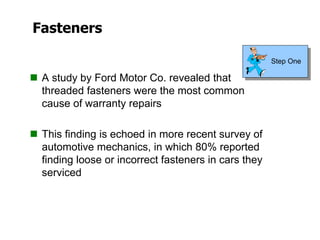

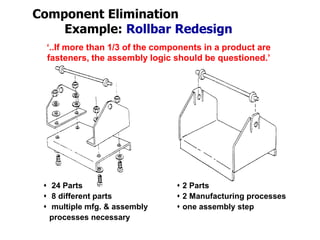

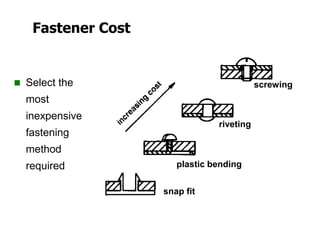

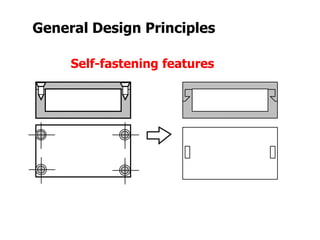

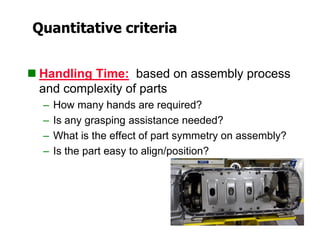

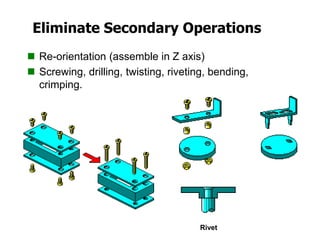

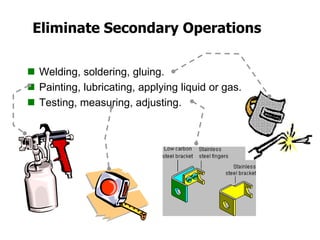

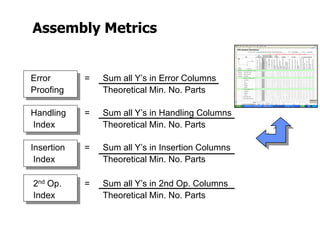

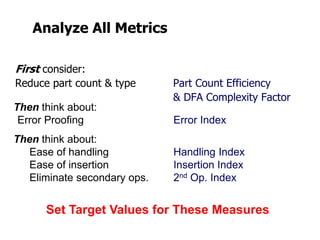

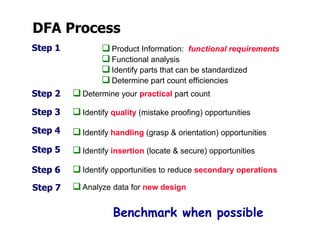

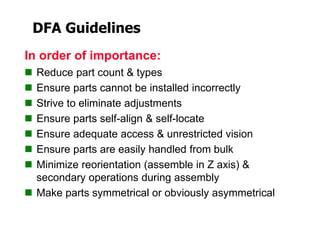

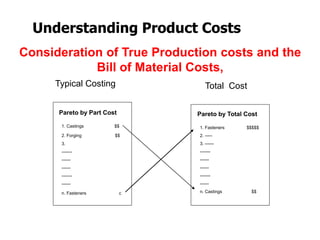

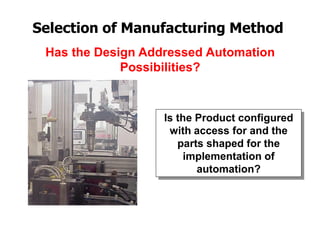

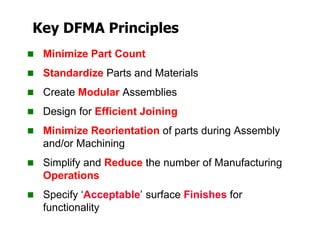

The document provides an overview of Design for Manufacturing and Assembly (DFMA) techniques. It defines DFMA as a methodology used to minimize product cost through design and process improvements. The objectives are to understand how product design influences cost, criteria for part minimization, quantitative analysis of design efficiency, and the importance of involving production engineers. Design for Assembly (DFA) focuses on reducing assembly cost by minimizing parts and operations, while Design for Manufacturing (DFM) aims to reduce part production cost through process optimization. Both seek to lower material, overhead and labor costs. The document outlines DFA and DFM principles and processes to analyze and optimize designs.