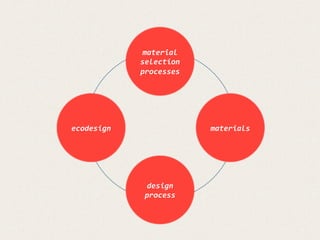

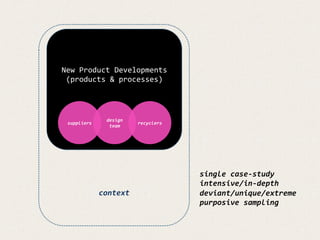

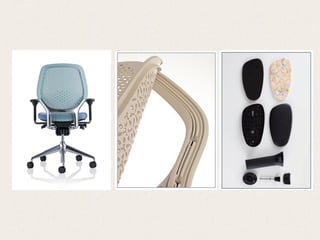

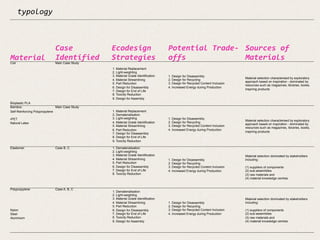

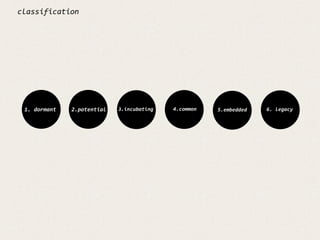

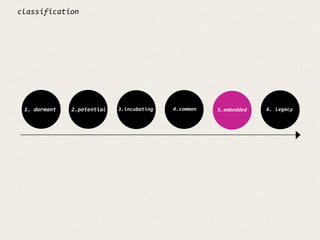

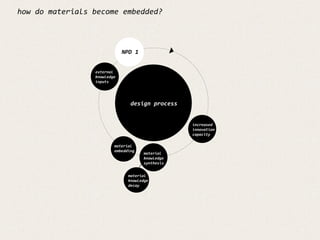

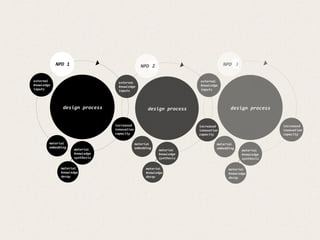

This document discusses material selection and design for sustainable innovation. It describes a case study of an SME manufacturing company in Wales that takes a design-led approach to innovation and has a mature sustainability profile. The case study examines the company's ecodesign processes for new product developments, with a focus on material selection and how materials become embedded in its design culture. The next stages of research involve integrating a developed typology with environmental assessment results and exploring how embedded material knowledge is developed.