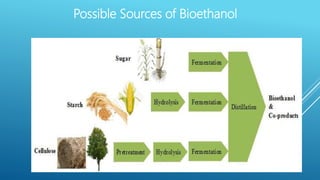

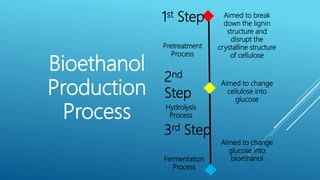

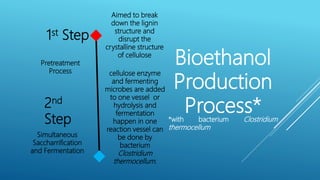

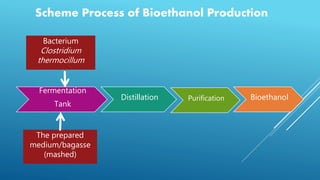

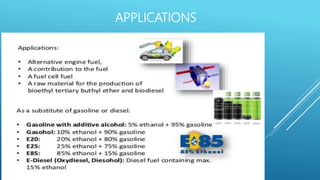

Bagasse, a waste product of sugarcane processing, can be used to produce bioethanol through fermentation. Bagasse contains cellulose that can be broken down through pretreatment and hydrolysis into glucose, then fermented by bacteria like Clostridium thermocellum into bioethanol. Producing bioethanol from bagasse provides an environmentally friendly alternative fuel and makes use of an agricultural waste product.