The document provides a detailed overview of ethanol, including its production process through fermentation, the types of microorganisms involved, and the various substrates used for its production. It explains the biochemistry of ethanol fermentation, the advantages of cell immobilization, and outlines the steps in the ethanol production process, along with its applications as a biofuel. Additionally, it highlights ethanol's role in reducing reliance on fossil fuels and its environmental benefits.

![Process contd…

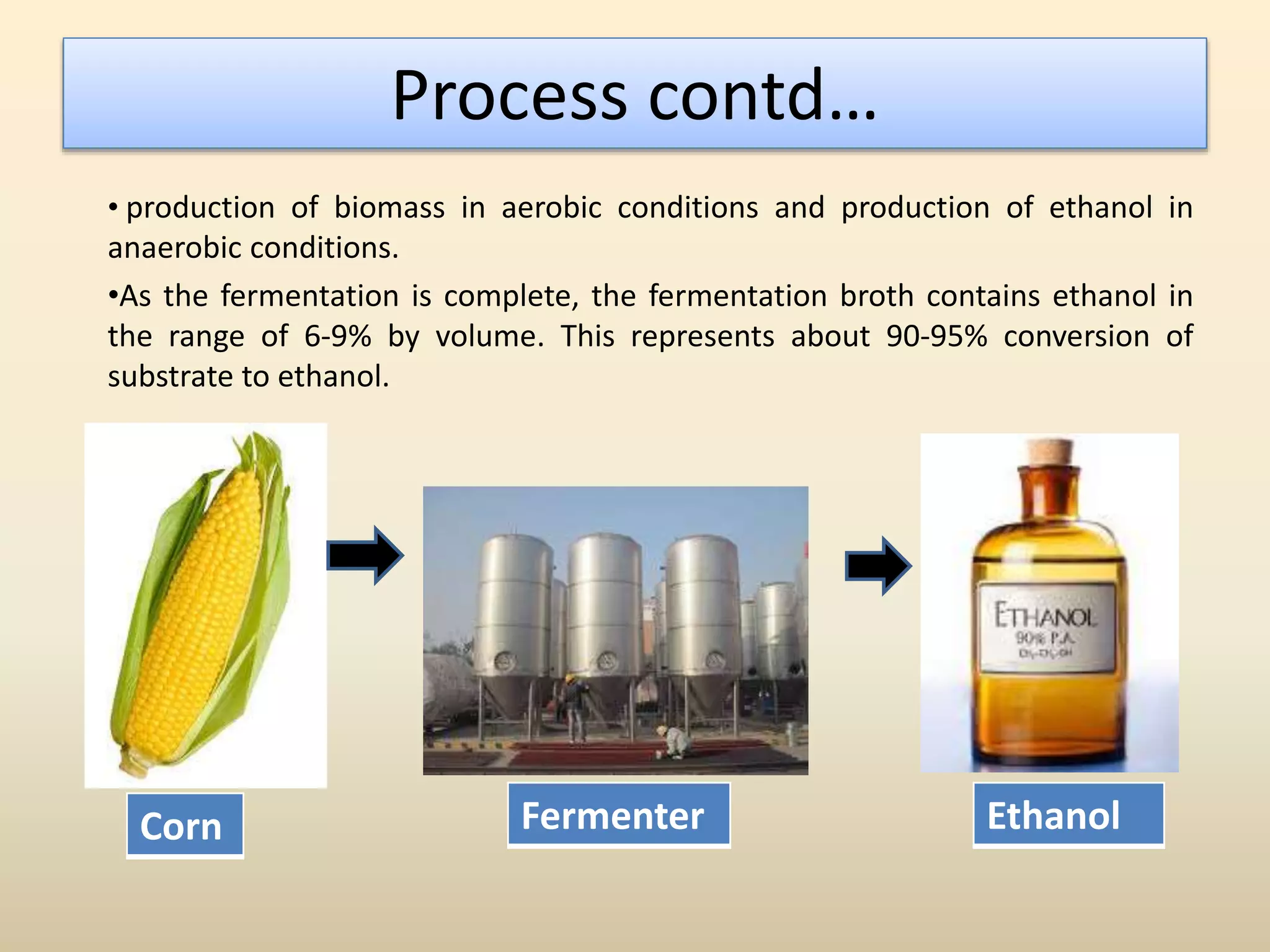

4. Fermentation process

•For the production of ethanol to occur properly, following conditions

should be maintained-

1.Fermentation conditions-

Temperature : a moderate temperature of 25ᵒC to 50ᵒC [ if the

temperature is too low, the yeast will be inactive and if it is too high,

the enzymes in the yeast will be denatured and will stop working]

pH : 4.0-4.5

Sugar concentration : higher glucose concentration rate does not

enhance the production of ethanol due to substrate inhibition at a

higher glucose concentration in the system.

2.Intrinsic Factors-

Culture medium

Dissolved Oxygen : Aeration is initially required for good growth of

the organisms. Later, anaerobic conditions are created by withdrawal

of oxygen coupled with production of CO2.

Immobilization

Other micronutrients.](https://image.slidesharecdn.com/ethanolproduction-180520064322/75/Ethanol-production-18-2048.jpg)