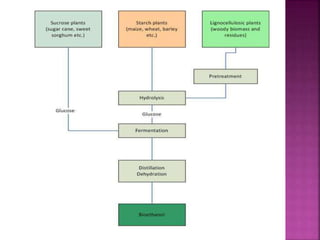

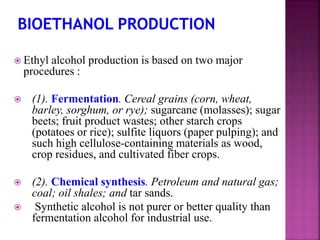

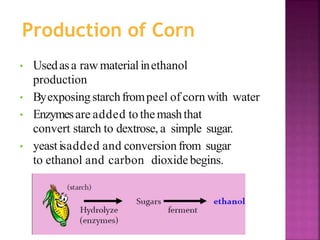

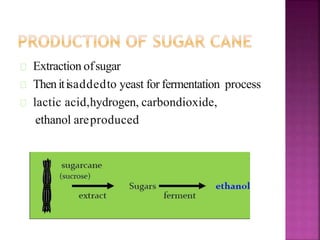

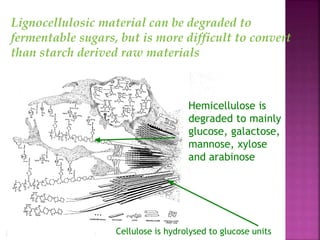

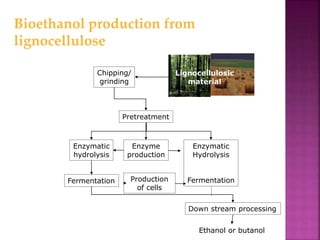

Bioethanol is produced through the fermentation of sugars from various agricultural sources like corn, sugarcane, and cellulosic materials. It has benefits as a renewable fuel that can reduce dependence on crude oil and emissions. There are three main steps in production: fermentation of sugars into ethanol, distillation to separate ethanol from water, and dehydration to purify the ethanol. Lignocellulosic materials like wood and crop residues can also be broken down enzymatically to produce fermentable sugars for ethanol production, but this process is more complex than using easily accessible starch sources. Bioethanol shows potential as a cleaner burning alternative fuel but still faces challenges in efficiency and infrastructure compatibility compared to gasoline.