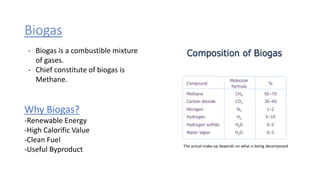

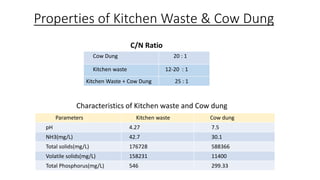

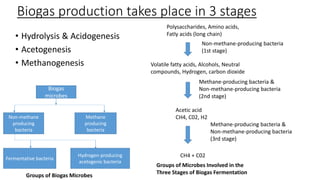

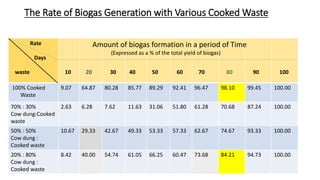

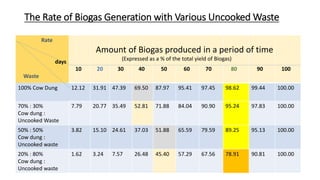

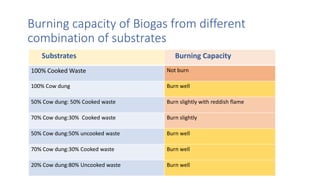

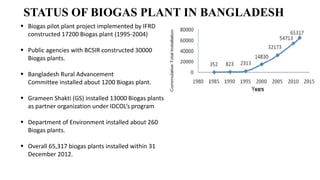

Biogas can be produced from the anaerobic digestion of kitchen waste and cow dung. The optimal carbon to nitrogen ratio for biogas production is around 25:1, which can be achieved by mixing kitchen waste and cow dung. Biogas production occurs in three stages through the action of various microorganisms and produces a gas that is around 60% methane. Studies found that mixing cow dung with kitchen waste produced more biogas than using either substrate alone. Approximately 65,000 biogas plants have been installed in Bangladesh so far but more are needed to utilize available waste resources and provide renewable energy.