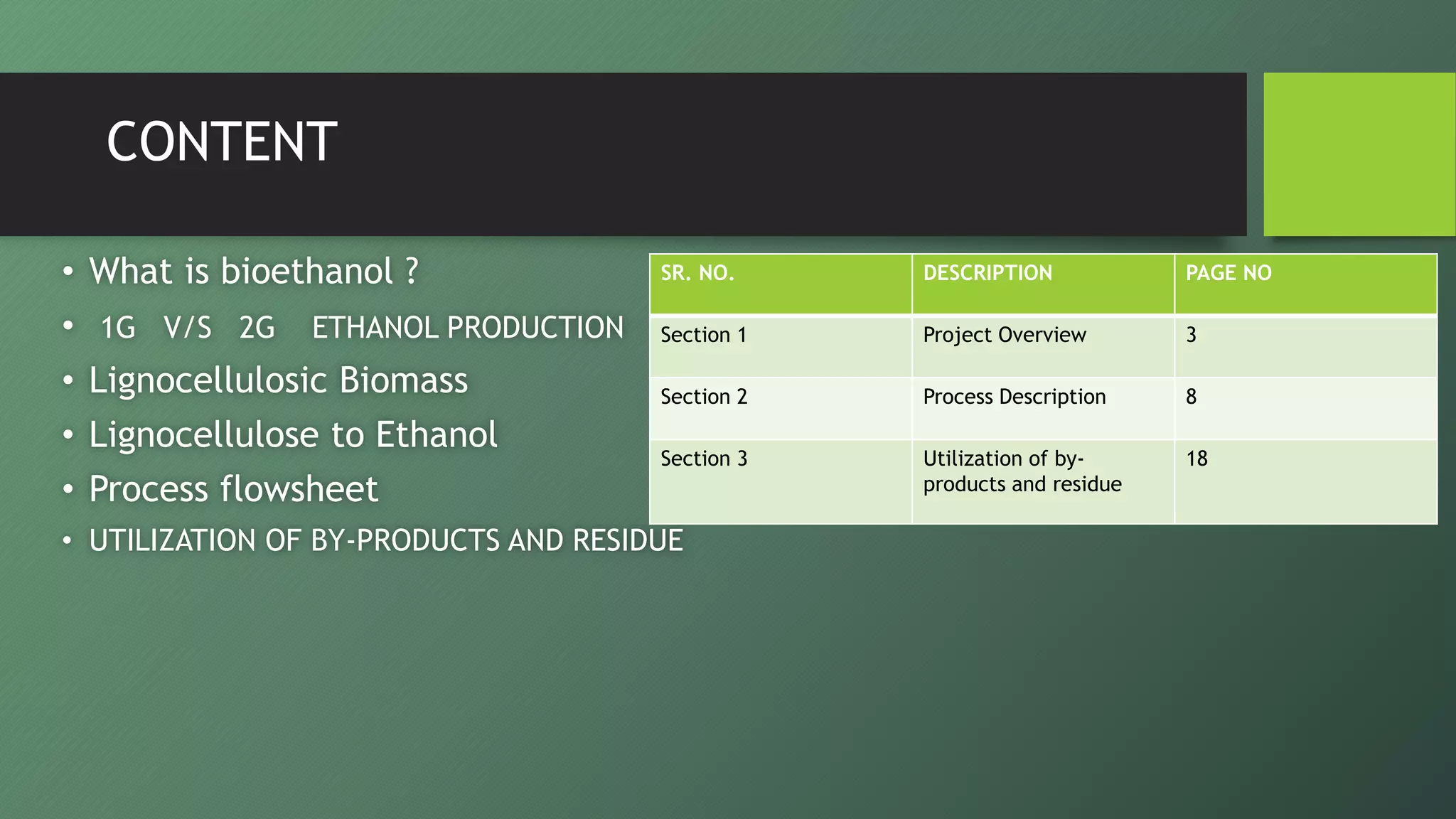

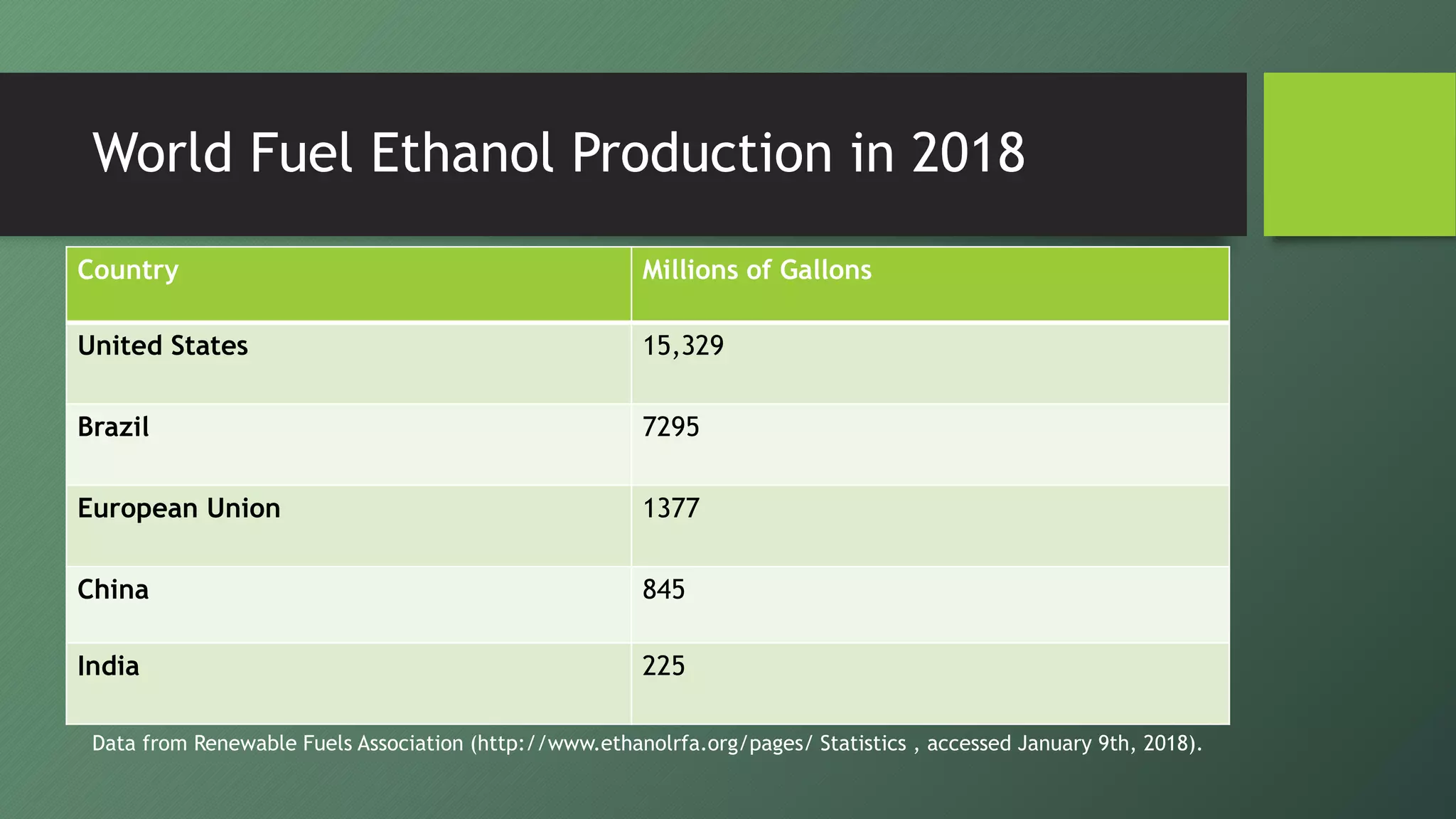

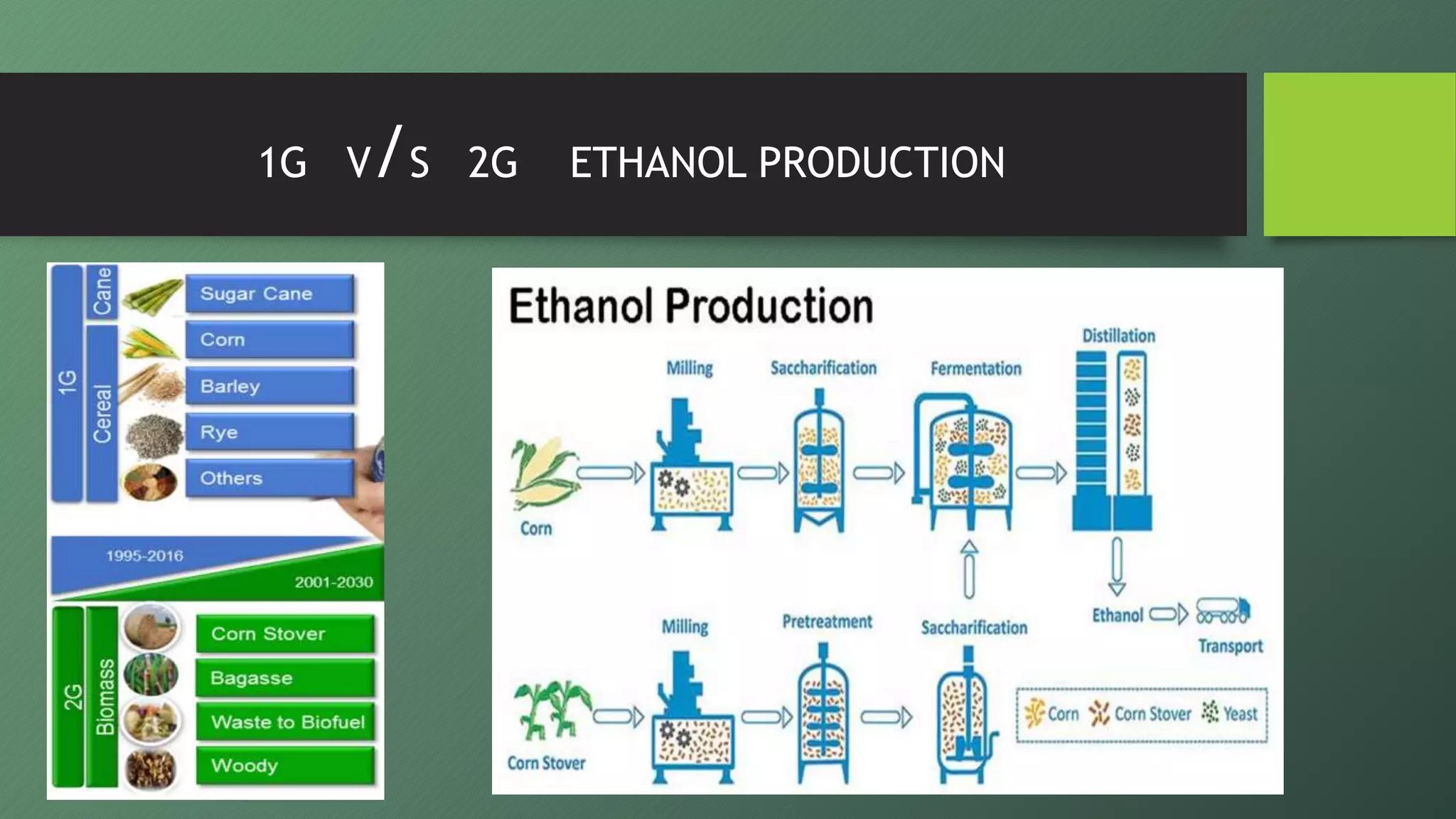

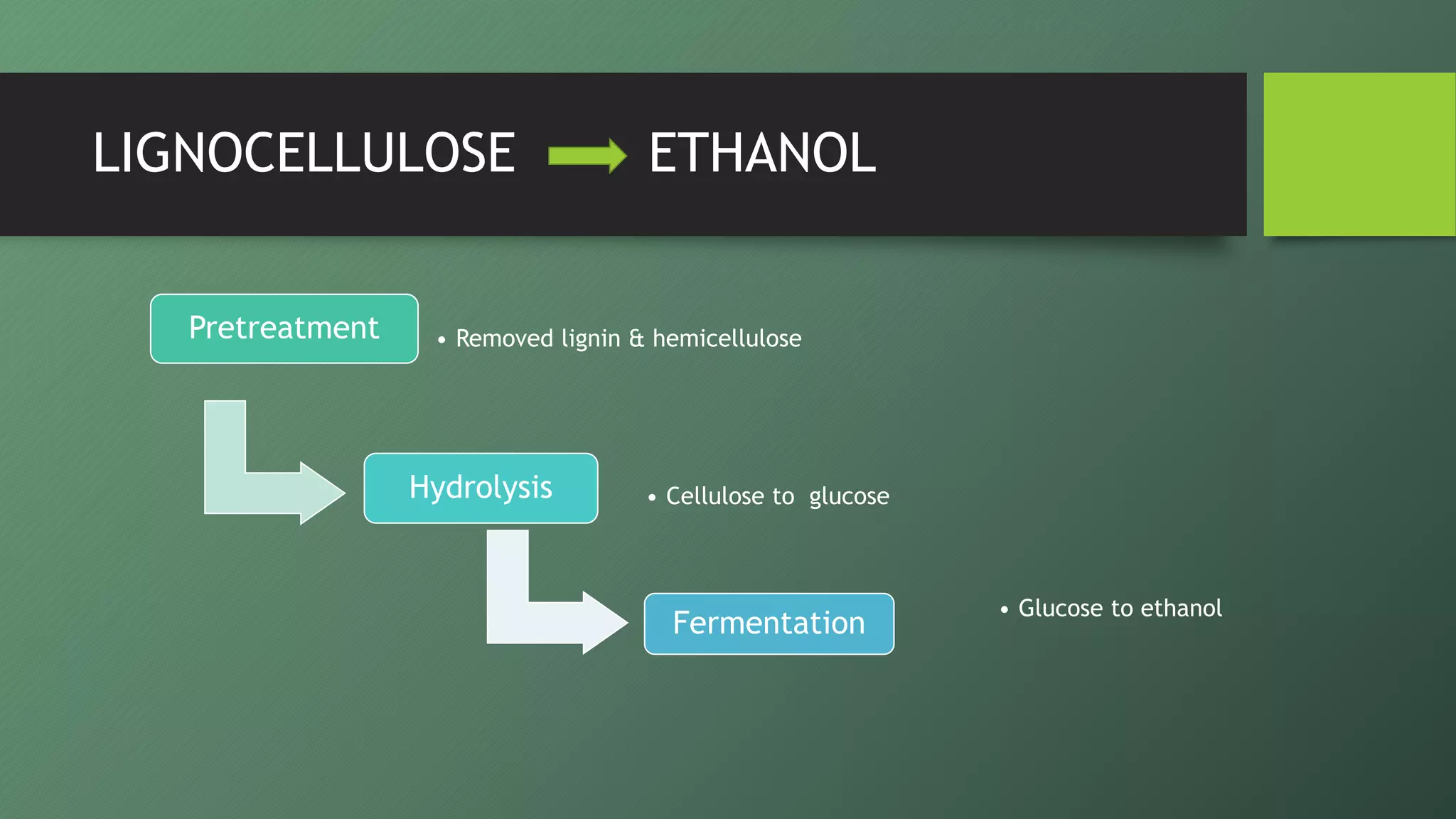

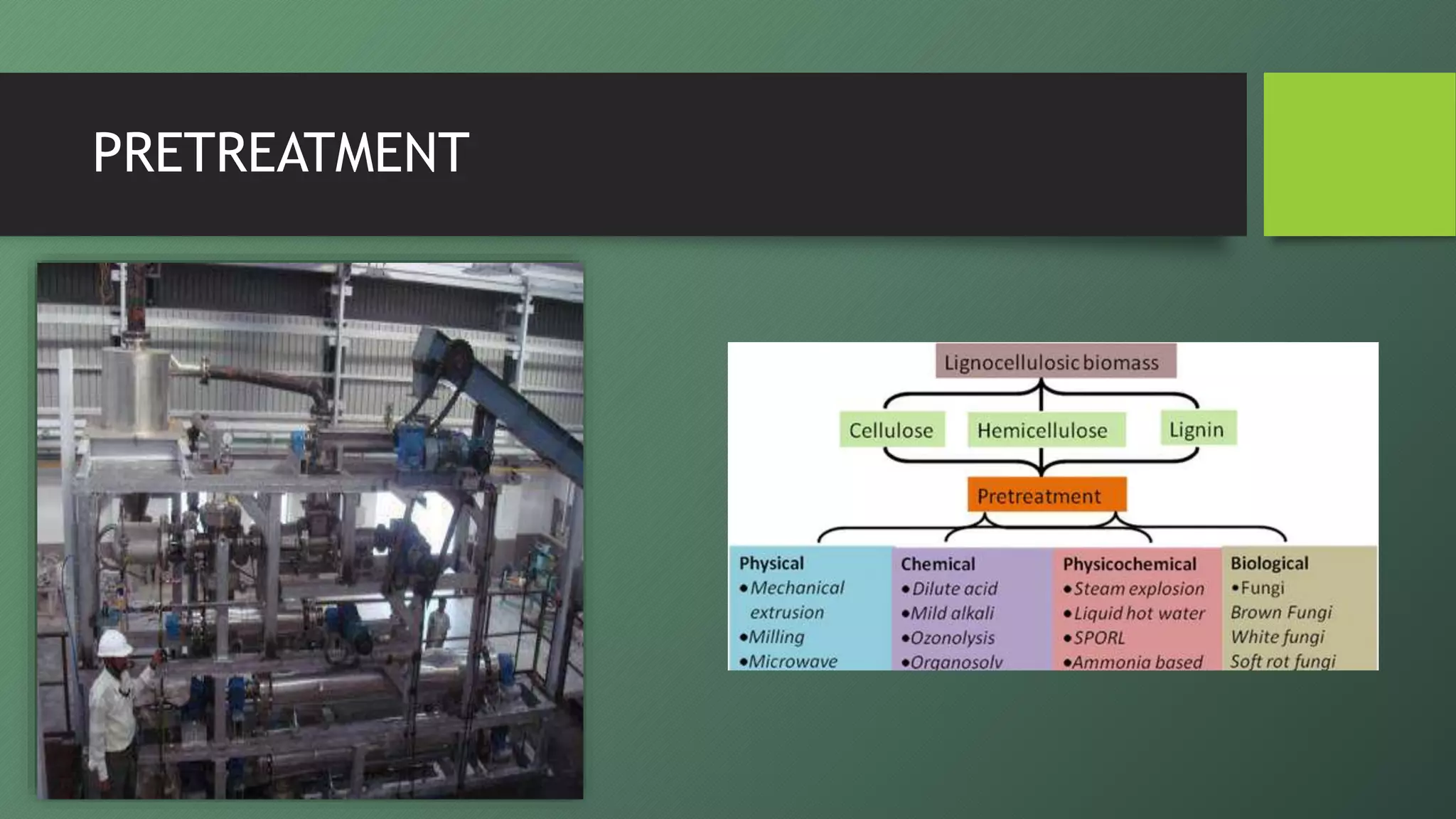

This document provides an overview of Nitinjay Singh's bioethanol plant design project. It first defines bioethanol and compares first and second generation ethanol production. It then outlines the process, which involves pretreating lignocellulosic biomass to remove lignin and hemicellulose, hydrolyzing the cellulose to glucose, and fermenting the glucose to ethanol. The document provides process flowsheets and describes several steps in detail, including material handling, pretreatment, enzymatic hydrolysis, fermentation, distillation, and dehydration. Finally, it discusses the utilization of byproducts and residues from the process.