Risk Assessments 96 pages

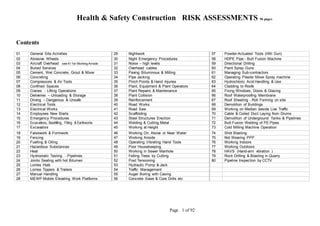

- 1. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 1 of 92 Contents 01 General Site Activities 29 Nightwork 57 Powder-Actuated Tools (Hilti Gun) 02 Abrasive Wheels 30 Night Emergency Procedures 58 HDPE Pipe - Butt Fusion Machine 03 Aircraft Overhead see 41 for Working Airside 31 Noise – high levels 59 Directional Drilling 04 Buried Services 32 Overhead cables 60 Paint Spray Guns 05 Cement, Wet Concrete, Grout & Mixer 33 Paving Bituminous & Milling 61 Managing Sub-contractors 06 Concreting 34 Pipe Jacking 62 Operating Plaster Mixer Spray machine 07 Compressors & Air Tools 35 Pinch Points & Hand Injuries 63 Hydrochloric Acid Handling & Use 08 Confined Spaces 36 Plant, Equipment & Plant Operators 64 Cladding to Roofs 09 Cranes - Lifting Operations 37 Plant Repairs & Maintenance 65 Fixing Windows, Doors & Glazing 10 Deliveries – Unloading & Storage 38 Plant Collision 66 Roof Waterproofing Membrane 11 Driving – Dangerous & Unsafe 39 Reinforcement 67 Roof Sheeting - Roll Forming on site 12 Electrical Tools 40 Road Works 68 Demolition of Buildings 13 Electrical Works 41 Road Saw 69 Working on Median beside Live Traffic 14 Employees New Starts 42 Scaffolding 70 Cable & Coiled Duct Laying from Drums 15 Emergency Procedures 43 Steel Structures Erection 71 Demolition of Underground Tanks & Pipelines 16 Excavations, Backfilling, Filling & Earthworks 44 Welding & Cutting Metal 72 Butt Fusion Welding of PE Pipes 17 Excavators 45 Working at Height 73 Cold Milling Machine Operation 18 Falsework & Formwork 46 Working On, Above or Near Water 74 Shot Blasting 19 Fencing 47 Working Airside 75 Not Wearing PPP 20 Fuelling & Oiling 48 Operating Vibrating Hand Tools 76 Working Indoors 21 Hazardous Substances 49 Poor Housekeeping 77 Working Outdoors 22 Heat 50 Working in Sewer Manhole 78 HAVS (Hand-arm vibration ) 23 Hydrostatic Testing - Pipelines 51 Felling Trees by Cutting 79 Rock Drilling & Blasting in Quarry 24 Joints Sealing with hot Bitumen 52 Post Tensioning 80 Pipeline Inspection by CCTV 25 Lorries Hiab 53 Hydraulic Pump & Jack 26 Lorries Tippers & Trailers 54 Traffic Management 27 Manual Handling 55 Auger Boring with Casing 28 MEWP Mobile Elevating Work Platforms 56 Concrete Saws & Core Drills etc

- 2. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 2 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk O1 Site Activities General 01 Construction activities Injuries Property Damage 6 6 36 Site HSE Project Procedures Work Permit Systems Method Statement for Risk Activities Risk Assessments On Site Safety Training HSE Supervision Issue of PPE COSHH Assessments On site Medical Clinic Site Emergency Response Plan Site Health, Safety & Environmental Plan First Aid Kits available First Aiders Site Inductions for Employees Welfare Facilities Waste bins Managers must take responsibility and accountability for HSE Management Training and implement above. 6 2 12 Adequately Controlled Risk 02 Abrasive Wheels

- 3. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 3 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 02 Disc Disintegration Electricity Entrapment / Entanglement Spoil Ejection Fire Noise Dust Lacerations [may be severe, even fatal. Contact burns / electric shocks Penetrating injuries Property damage Tinnitus / Threshold shift / Noise induced Hearing loss Respiratory problems Eye Injury 6 6 36 Use of approved suppliers Use of appropriate speed rated discs Use of task specific discs Use of correctly adjusted guards Use of suitable PPE ( body / hands / face / eyes /ears ) Trained and competent persons only to use abrasive wheels / change discs All electrical equipment to be 110V with industrial sockets Routine inspection / testing All electrical equipment colour coded Damaged equipment tagged and taken out of service All cutters and grinders regularly maintained No loose clothing worn Adequate training & supervision Use of Hot work permit system Fire points available Trained fire extinguisher operatives Removal of combustible materials Sound screens / isolation of high noise activities Abrasive wheel signs. Eye protection – high impact glasses at all times. Eye wash station on site 6 2 12 Adequately Controlled Risk 03 Aircraft Overhead

- 4. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 4 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 03a Collision with aircraft in flight Severe physical damage Fatalities Public outcry 10 6 60 Fan corridor height restrictions briefed to all site teams Works in the fan corridor will be controlled by Restricted Area Access Work Permits Heightmarkers ( such as goal posts ) shall be constructed as applicable to advise of heightlimits All plantequipmentshall be selected on basis of maximum operating heights so as to notinterfere with airportoperations Authorisation from 3rd party. Supervision atall times. MS/ RA briefed to all affected workers 10 2 20 Adequately Controlled Risk 03b Lighting Distraction to Pilots on Finals to landing Severe physical damage Fatalities 10 4 40 Tower lights to be setup so the light beam shines across the runway (North to South) so as not to be a distraction to pilots on finals to landing. The heightof tower lights to be limited to 13m. Lighttowers established on raised bridge decks to be approved by OAMC Lights to have welded restrictors to ensure the light beam is downwards facing. Lighting control will be via liaison with the OAMC MS/ RA briefed to all affected workers A lighting plan will be prepared and submitted prior to any nightwork, showing location and direction and illuminated area oflightbeams. 10 2 20 Adequately Controlled Risk 04 Buried Services 04 Underground services ;- gas, electricity or water Personal Injury – electrocution / drowning / 8 6 48 Area to be visually checked for markers or physical signs of services, i.e. manholes. Up to date drawings detailing existing services 6 2 12 Adequately Controlled Risk

- 5. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 5 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk asphyxiation Property Damage Fire Disruption of utility services shall be obtained and checked thoroughly. Service providers shall be contacted to assess if there are services in the area and also to let them know work is going to be carried out. Obtain permit from Utility Company if required. Use of trial holes and hand excavation around known services Hand tools that are non conductive shall be used when excavating around existing services. Prior to excavation the affected area shall be surveyed with a CAT and competent person. Records of all CAT surveyed areas to be kept on file and briefed to excavation team Surveyed area clearly demarked on site NOC from municipality to be obtained before excavation Emergency contact numbers displayed on site Where required use Permit to Dig. Obtain NOC where applicable Protect existing services by either, marking the ground surface, providing protection slabs, tiles or timbers or exposing & encasing in concrete. 05 Cement, Wet Concrete, Grout & Mixer a. Handling Cement Contact dermatitis / skin irritation Cement dust 6 6 36 Wear suitable protective eye wear Compliance with COSHH assessment Have eye station on hand 6 2 12 Adequately Controlled Risk

- 6. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 6 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk inhalation Eye Injury Wash hands after each exposure Use of gloves Use of full length uniforms First Aiders available b Handling wet concrete & grout Contact dermatitis / skin irritation Eye Injury 6 6 36 Wear suitable protective eye wear Compliance with COSHH assessment Have eye station on hand Wash hands after each exposure Use of gloves Use of full length uniforms First Aiders available 6 2 12 Adequately Controlled Risk c Using Mixers Personal Injuries to include cuts and crush injuries Electrocution Contact dermatitis / skin irritation Electric shocks / contact burns Tinnitus / Noise induced hearing loss Cement dust inhalation 6 6 36 All necessary guards are to be in place on the mixer. All equipment is to be inspected by a competent person prior to use. Only trained operatives to use mixer Planned preventative maintenance programs No persons are to put tools or limbs in to mixer while drum is rotating. Mixer is to be set up on firm level ground and should never be over loaded. All mixers should be 110 volt to prevent electrocution. All temporary plant to be suitably earthed Use of suitable PPE ( body / face / eyes/ hands /ears ) Adequate training & supervision Tool box talks ref manual handling Noise levels assessed and sound screens provided as required 6 2 12 Adequately Controlled Risk

- 7. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 7 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Availability of first aid / eye wash station Compliance with COSHH assessment Use protective mask. 06 Concreting 06a Hazardous chemicals Burns, Contact Dermatitis Eye irritations 6 4 24 Selection and use of Appropriate PPE ( body / hands /face /eyes / ears) Wear eye protection Eye wash station nearby. First Aid nearby Trained first aider Completion of COSHH Assessment Use friendly chemicals Washing facilities will be provided with hot water, showers, soap & paper towels First Aid & First Aid Equipment provided 6 2 12 Adequately Controlled Risk 06b Vibration. Vibration-induced white finger 6 4 24 Limit exposure time / regular breaks Job rotation Selection and use of appropriate PPE Operatives will be briefed on dangers 6 2 12 Adequately Controlled Risk

- 8. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 8 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 06c Falls on working levels or from height Personal Injury Deaths Serious injury 6 4 24 Provide leading edge protection and safe access. Good housekeeping disciplines Adequate training & supervision Training and supervision 6 2 12 Adequately Controlled Risk 06d Prolonged exposure to noisy plant Tinnitus, threshold shift , Noise induced hearing loss 4 4 16 Ear Protection if you have to shout to be heard. Monitor noise levels and enforce PPE use above 85dB Place warning signage for noise If you have to shout to be heard wear ear protection 4 2 8 Trivial Risk 06e Failure of support system or platform Personal Injury Property damage 6 4 24 Structural sign off for all falsework and formwork before any concrete placement 6 2 12 Adequately Controlled Risk 06f Concrete Pumps Property damage Personal Injury 6 6 36 All equipment is to be inspected by a competent person prior to use. Whip checks fitted on pressure hoses Operator has Valid license / certification Exclusion zone created around working concrete pump Noise levels assessed and PPE provided as required No manual clearance of pump hopper while 6 2 12 Adequately Controlled Risk

- 9. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 9 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk pump is in operation Adequate training & Supervision Pump is to be set up on firm level ground with outriggers fully deployed using load pads. Wash-out facility will be provided and for night work will be illuminated. Clean out in an area set aside for this particular activity. Exclude people not involved in the clean out procedure from the work zone. Do not “Shoot” the clean out plug from the end of the concrete line. 06g Wastage Environmental damage 6 4 24 Use Wash-out facility provided around the site and in the concrete batching yard 6 2 12 Adequately Controlled Risk 07 Compressors & Air Tools 07 Airlines Whipping Noise Injury 6 2 12 Use whip wire on airlines Visual inspection of air hoses prior to starting work, any damaged hoses to be replaced No horseplay with airlines or misuse Ear & Dust protection Exhaust fumes not to cause hazard 6 2 12 Adequately Controlled Risk Jackhammer Vibration white finger Eye injuries Hearing loss HAND ARM VIBRATIONS (HAV) 6 4 24 Anti-vibration tools used if possible Eye protection to grade one impact when using metal cutting or stone cutting tools Heavy leather gloves when using tools causing hand-arm vibration Suitable protective gloves when handling parts contaminated with hydraulic fluid 6 2 12 Adequately Controlled Risk

- 10. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 10 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Hearing protection Respiratory protection against dust where assessed as necessary Safety boots with Airlines Air hoses should be laid out properly without kinks and not in the way of machinery movement Rotate workers when using tools that produce HAV and record time on tools per shift. 08 Confined Space Note difference between Permit and Non-Permit confined spaces Refer to HSE Project Procedure for Confined Spaces Entry Doc # PP710-CSE-1008 08a Increased or decreased oxygen levels Asphyxiation 6 6 36 Use of confined space permit system Atmospheric testing. Suitable means of communication No lone working permitted Emergency plan in place ( rescue from Confined Space etc ) Adequate ventilation / lighting Suitable access points ( preferably 2 points where poss. ) Hourly records of Gas levels Signage /exclusion zone to prevent unauthorized access Training & Supervision Good housekeeping 6 2 12 Adequately Managed

- 11. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 11 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 08b Hazardous gases Poisonings 4 6 24 Atmospheric testing. Use of confined space permit system Adequate ventilation / lighting Hourly records of Gas levels 4 2 12 Adequately Managed 08c Fire Burns 4 6 24 Fire points available No Smoking Exclude inflammable materials & liquids Intrinsically safe lighting, emergency lighting and torches. 4 2 8 Negligible Risk Non Permit Confined Space 08d Fumes Injury 6 4 24 Good access & egress routes Smoking Prohibited No Working Alone No petrol or diesel engines No combustible material stored Natural Ventilation 6 2 12 Adequately Controlled Risk Permit Confined Space 08e Hazardous Gases Injury 6 4 24 Note - Depending on circumstances select from following Good access & egress routes Smoking Prohibited No Working Alone 6 2 12 Adequately Controlled Risk

- 12. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 12 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk No petrol or diesel engines No combustible material stored Natural Ventilation Permit to Work System Personnel Training in Confined Spaces Lights Instrinically Safe Gas Dectors Entry Log System Force Ventilation Rescue Harness ( connected to Lifeline leading to outside) Rescue Equipment Self Rescuers carried 09 Cranes – Lifting Operations General Comply with Project Procedure for Lifting Operations PP 738-LOP-1008 Wind Speed Limit on Site is 9m/sec or 32.5Km/hr Notes Slinger = Rigger Signaller = Banksman 09a Crane overturning Personal injury Property damage 6 4 24 Crane set up on firm and level ground Outriggers to be fully extended Load pads under all outriggers 6 2 12 Adequately Controlled Risk

- 13. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 13 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Crane set up controlled by competent lifting supervisor Crane has PMV inspection prior to mobilisation Crane has valid 3rd party inspection certification. Licensed crane operator Selection of correct crane for task ( SWL etc ). Weights of loads known before lifting Exclusion zones created around lifting operations Daily checks by operator recorded No work in strong winds Certified slings, shackles and other lifting appliances to be used & be in period colour code. Do not exceed SWL Check area under outriggers for drains etc 09b Crane failure Personal Injury Property damage 6 4 24 Crane set up on firm and level ground Outriggers fully deployed Load pads under all outriggers Crane set up controlled by competent lifting supervisor Crane has PMV inspection prior to mobilisation + daily pre use inspection Crane has valid 3rd party inspection certification. 6 2 12 Adequately Controlled Risk

- 14. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 14 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Licensed crane operator Selection of correct crane for task (SWL etc ). Weights of loads known before lifting Exclusion zones created around lifting operations Daily checks by operator prior to starting Do not exceed SWL 09c Failure of lifting equipment Personal Injury Property damage 6 4 24 All lifting equipment shall be 3rd party inspected and certified as fit for purpose, All areas of lifting operations shall be adequately lit Crane operators to have valid licenses All lift accessories shall be inspected, certified and comply with CCC /TAV JV colour coding scheme for the period Specific lift paths will be created to avoid any overhead lifting All cranes or lifting operations shall be controlled by competent signal man All rigging activities shall be conducted by trained and competent rigger. Exclusion zones with fixed barriers will be established around lifting operations / zone All operations supervised Equipment to comply with colour code for period Select correct lifting accessories for planned load. All lifting accessories to be checked daily by 6 2 12 Adequately Controlled Risk

- 15. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 15 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk crane driver and riggers before use. 09d Rigging Personal Injury Property damage 6 4 24 All lifting tackle shall be 3rd party inspected, certified and CCCTAVJV colour coded Rigging operations shall only be performed by trained & competent riggers. All lifts will be controlled and supervised by a rigging supervisor. Lifting plans will be used for all abnormal loads Exclusion zones created around lifting operations Personnel will be advised of risks through tool box talks prior to commencement of work. All riggers shall wear appropriate PPE Riggers shall be identifiable via helmet colour Tag lines used for all lifts Helmets colour coded All lifting accessories to be checked daily by crane driver and riggers before use. 6 2 12 Adequately Controlled Risk

- 16. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 16 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 09e Equipment & Material Handling Personal Injury Property damage 6 4 24 All equipment will be stored, handled in a safe and proper manner & managed by trained staff. Offloading and storage will be properly controlled / supervised at all times by trained staff at all times. Tag lines will be used to control equipment during loading and offloading. Personnel will be properly trained in safe methods of Equipment handling including the danger of pinch points – fenced off. Erection areas will be identified and unauthorized entry will be controlled by use of barriers, warning signs and close supervision. Appropriate personnel protective equipment will be worn at all times. Personnel will be reminded of risks through tool box talks. Period colour coded equipment. Beware of trapping while moving loads 6 2 12 Adequately Controlled Risk 09f Adverse weather Property damage Personal injury Crane failure 6 6 36 Install anemometers on cranes / site Safe operating limits for wind speed set for all lifting operations Liaison with OAMC meteorology dept. Protocols for all adverse weather situations such as sand storms established Training and competent supervision Crane supervisor with authority to suspend all lift operations project wide 6 2 12 Adequately Controlled Risk

- 17. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 17 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Crane driver and riggers authorised to stop lifts if deemed unsafe or high winds 09g Multiple Cranes & suspended loads Collision Personal injury Property damage 6 6 36 Crane & suspended loads, Anti Collision Measures Banksman to guide and coordinate the movements of cranes working in close proximity. Vehicles not to be parked in swing area of cranes No person to stand sit or walk near working cranes No unauthorised access Exclusion zones created around working plant 6 2 12 Adequately Controlled Risk 09h Working in crane suspended man baskets Personal injury 6 6 36 Basket will be certified by 3rd Party Personnel will wear harnesses Adequate signage and exclusion zones around temporary structures. 6 2 12 Adequately Controlled Risk 10 Deliveries Unloading & Storage 10 Moving Delivery Vehicles Entering/Leaving site Traffic accidents Property damage Personal injury 6 6 36 Good visibility of oncoming vehicles. Traffic calming measures such as speed bumps Pedestrian routing. High visibility clothing. 6 2 12 Adequately Controlled Risk

- 18. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 18 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Reversing alarms. All vehicle reversing controlled by trained banksman. Banksmen not to get between moving vehicles and fixed objects Adequate signage Adequate lighting at site entrances Site driving rules posted Security marshalling traffic All CCCTAVJV / Subcontractors drivers HSE inducted All drivers to hold valid Omani license Authorised vehicles only on site Security identify drop zones & advise delivery drivers on site traffic rules. Unloading Injury Material damage 6 6 36 Comply with Lifting Operations project Procedure PP 738 6 2 12 Adequately Controlled Risk Storage Injury Material damage 6 6 36 Stack materials in designated areas Cordon off area Keep storage area tidy 6 2 12 Adequately Controlled Risk 11 Driving – Dangerous or Unsafe 11 Dangerous or unsafe driving Road traffic accident Personal Injury Property damage 8 6 48 Designated and signposted access routes required. All drivers must have an appropriate license 8 2 16 Adequately Controlled Risk

- 19. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 19 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk for the particular piece of plant they are using. All personnel involved in the work shall be inducted, instructed on the site driving rules and have their license checked and recorded. Regular tool box talks and Night Activity Briefings (NAB) shall be given to reiterate driving standards. Supervisors and H&S shall monitor driving and take appropriate action if necessary. All reversing vehicles to be controlled by a trained banksman All mobile plant to have audible reversing alarm Blind spots to be mitigated by appropriate mirrors. . All necessary lights should be in place on vehicles including orange flashing beckons and should be used at all times as well as being regularly inspected. Vehicle Lights, windows and mirrors shall be cleaned regularly to ensure a clear view. 12 Electrical Tools 12 Electricity Moving parts Noise Vibration Dusts Personal Injuries: Cuts and lacerations. Potential amputations Penetrating Injuries. Respiratory problems Upper limb work disorders Vibration white finger. Electrocution. 4 6 24 110Volt tools only permitted on project Use of approved industrial sockets Inspected and CCCTAVJV colour coded HSE Induction for all workers. Toolbox talks. Selection and use of suitable PPE. Adequate training and supervision. Tool maintenance and record keeping. Damaged tools tagged, isolated and removed from service 4 2 8 Trivial Risk

- 20. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 20 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk All tools fitted with appropriately adjusted guards. Pre use daily inspections PAT test to all Electric equipment. Job rotation as required & recorded. Equipment to comply with the site colour code for period 13 Electrical Work 13 Using Electrical Equipment. Electrical installation works Electrocution. Fire. Property damage 4 4 16 All Electrical Distribution boards shall be fitted with suitable circuit breakers All hand tools on site shall be 110V Use of approved industrial sockets Only authorized and trained personnel to carry out work with electrical equipment. Only trained and authorised personnel to complete electrical installations ( DB’s etc ) Portable equipment to be checked by authorized electrician or independent assessor. All electrical equipment shall be colour coded Suitable fire extinguishers stored at strategic locations. Training in use of extinguishers Any damaged equipment to be removed from use, isolated and tagged to prevent accidental re-use No ‘hot wiring / splicing of cables ‘ on site Lock out tag out system ( for DB boxes etc ) Suitable earthing for all temporary plant Suitable training and supervision 4 2 8 Trivial Risk 14 Employees New Starts 14 Inexperience of Increased risk of 4 4 16 Induction training. 4 2 8 Trivial Risk

- 21. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 21 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk New Employees unsafe activities Potential poor quality works Personal Injury Property damage Training in site rules and procedures. HSE training programs Close supervision / use buddy system Pre planning of tasks assigned based on experience required Issued with PPE Issued with Identification Card 15 Emergency Procedures 15 Emergency situations / poor emergency procedures. Disruption to project Personal injuries Property damage Worsening of an incident if dealt with incorrectly 6 6 36 Project specific emergency plan created Emergency procedure included in induction and reiterated in briefings and Tool box talks. Emergency contact details posted on site notice boards and office bulletin boards Emergency contact detail cards distributed to all supervisory staff Emergency facilities on standby ( ambulance / fire engine / clinic ) Trained First Aiders available throughout the site Trained fire wardens available throughout the site Fire points / first aid boxes available throughout the site Incident control room established at MC 1 offices Duty Incident Controller Rota established Scheduled emergency drills Liaison with civilian emergency services. All personnel to have Emergency # Security at gates. Emergency drills. 6 2 12 Adequately Controlled Risk

- 22. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 22 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 16 Excavations, Backfilling, Filling & Earthworks General Comply with Project Procedure PP712-EXE- 1008 Any excavation left open for 7days or more to have a weekly inspection carried out and recorded within 24 hours. Provide safe access & egress 16a Trench Collapse Entrapment Death Injury 6 6 36 Slope or step faces Daily excavation inspections Permit to Dig in place. Keep spoil and plant 2 metres away from edge of excavation Keep excavations dry, water at safe level. 6 2 12 Adequately Controlled Risk 16b Persons falling into excavations Personal Injury Property damage 6 6 36 All excavations will have suitable fixed barriers at least 1.5m from leading edges Provision of adequate signage Creation of safe pedestrian access routes away from excavations Safe access and egress shall be provided for all excavations and access bridges over the trenches should be provided if required. Excavation daily inspection checklist to be completed by competent person 6 2 12 Adequately Controlled Risk

- 23. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 23 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Training & Supervision Regular TB Talks ref: excavation safety 16c Material or plant falling into excavations including trench collapse Personal Injury Property damage 6 6 36 All excavations will have suitable fixed barriers at least 1.5m from leading edges All excavated spoil to be placed at least 2m from leading edges Provision of adequate signage Creation of vehicle access routes away from excavations Safe access and egress shall be provided for all excavations and access bridges over the trenches should be provided. No lone working in excavations Excavation daily inspection checklist to be completed by competent person Training & Supervision Regular TB Talks ref: excavation safety Stop blocks shall be used where plant is working near the trench. The stop blocks must of sufficient height and strength to stop the vehicle and of sufficient distance from the trench so as to stop collapse. All excavations of greater depth than 1.2 shall have a suitable means of ground support such as. battering, benching, trench sheets, trench boxes, sheet piling, etc. In solid and non fractured rock the above requirement may be relaxed Adequate angle of repose shall be in place for 6 2 12 Adequately Controlled Risk

- 24. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 24 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk all excavations where above ground support measures are not possible Lighting as required 16d Weakening of adjacent structures by excavation Collapse of structure Property damage Personal Injury 6 4 24 Suitable prior planning of shoring requirements before works commence. Structural engineer to advise on any additional shoring / support required. Daily check inspections 6 2 12 Adequately Controlled Risk 16e Buried Services gas, electricity water Personal Injury – electrocution / drowning / asphyxiation Property Damage Fire Disruption of utility services 8 6 48 Area to be visually checked for markers or physical signs of services, i.e. manholes. Up to date Drawings detailing existing services shall be obtained and checked thoroughly. Liaison with concerned authority Use of trial holes and hand excavation around known services Hand tools that are non conductive shall be used when excavating around existing services. Prior to excavation the affected area shall be surveyed with a CAT by a competent person. Records of all CAT surveyed areas to be kept on file and briefed to excavation team Surveyed area clearly demarked on site NOC from municipality to be obtained before excavation 6 2 12 Adequately Controlled Risk 16f Overhead Power Lines Personal Injury – electrocution / burns Property Damage 6 6 36 Selection of appropriate plant in respect of max operating heights 6 2 12 Adequately Controlled

- 25. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 25 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Fire Disruption of utility services Erect barriers with warning signs parallel Erect goal posts with cross bars for passing under All plant movement under overhead power lines controlled by trained banksman All plant and temporary scaffolds to be suitably earthed to safeguard against arcing All drivers and plant operators to receive Tool box talks Security to stop all vehicles and warn drivers of any overhead power line hazards Exclusion zones created to prevent encroachment of plant & vehicles near overhead lines Competent supervision Reroute service where possible Follow CCCTAVJV procedure Operate Permit to Work Safe System of Work in place Working under or around Power Lines Procedure in place. Re route power lines where possible. Overhead power line procedure in place. Notify service company Obtain NOC 16g Access & Egress Falling, Injuries 6 6 36 Ensure that all access ladders are in good condition and are inspected 6 2 12 Adequately Controlled

- 26. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 26 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Ensure that all access Ladders are tied on top Ensure that the ladders are standing on stable ground Areas at top and bottom to be free from materials and debris. Ladders to be industrial type not home made Ensure that the ladders are supported on bottom in case tying the top is not possible Ensure that no rebar or other objects are protruding into the ladders Operators shall remove lumps of material from footwear prior using ladders 16h Working in vicinity of moving plant Injury Property Damage 6 4 24 All plant to be operated by suitably licensed and competent operators. All reversing vehicles to be controlled by a trained banksman All mobile plant to have audible reversing alarm Blind spots to be mitigated by appropriate mirrors. Site driving rules enforced. All necessary lights should be in place on vehicles including orange flashing beckons and should be used at all times as well as being regularly inspected. Vehicle Lights, windows and mirrors shall be cleaned regularly to ensure a clear view. Exclusion zones created around working plant Emergency procedures in place 6 2 12 Adequately Controlled Risk

- 27. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 27 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 17 Excavators 17a Working excavator Excavator failure Personal Injury [may be severe, even fatal] Property damage. Traffic accidents 6 6 36 All excavator operators to hold valid license / certification All operators familiarised with the SAFE WORKING PROCEDURE FOR EXCAVATORS. Prior to mobilising all excavators to be inspected by PMV Operator to carry out visual inspection of machine prior to start up. All excavators shall deploy outriggers if fitted Visibility blind spots to be minimised by mirrors. Flashing beacon fitted. Windows, lights, Mirrors to be cleaned regularly. The cab floor to be kept clean and free from any obstacles which may affect the safe operation of the Machine. Ground workers to wear Hi Visibility Vests, safety boots and helmets at all times. Exclusion zone to be created around working excavators All excavators to be included in Planned Preventative Maintenance schedule All excavators to have Fire extinguisher in cab 6 2 12 Adequately Controlled Risk

- 28. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 28 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Spill kits available on site Banksman to supervise & direct driver. No persons to be in any trench or excavation during machine excavation work. With quick hitches – locking bars or self locking pins to be fully inserted and visually checked by driver. . 17b Lifting operations Property damage Personal injury Machine overturn 6 6 36 Fully deployed outriggers Posted SWL on machine Selection of appropriate plant for task ( SWL etc ) Competent rigging Suitable lifting attachments / eyes on machine – certified Exclusion zone In date equipment colour code. Only lift using the lifting eye and not the teeth of the bucket. 6 2 12 Adequately Controlled Risk 17c Rockbreakers Hearing Injury 6 6 36 Wear ear muffs Wear Goggles 6 2 12 Adequately Controlled Risk

- 29. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 29 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 18 Falsework / Formwork 18 Structural collapse Personal Injury Property damage 6 4 24 Falsework designed by structural engineer Separate MS / RA for each bridge MS/ RA briefed to all affected workers Structural engineer inspection, approval & sign off prior to any loading of falsework Formwork inspected / signed off prior to any concrete placement Provide proper access and egress routes Erect and strip falsework & formwork as per design drawings 6 2 12 Adequately Controlled Risk 19 Fencing

- 30. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 30 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 19a Sharp wire to be fitted to fence by hand Cuts to hands, face and body. 6 6 36 All personnel using and fitting the barbed wire should be trained, experienced and competent in the use of the material Coveralls, appropriate gloves and face shield to be worn by personnel fitting and handling barbed wire material. None essential personnel to be kept away from area barbed wire is being used by barriers with signs erected to high light the issue. 6 2 12 Adequately Controlled Risk 19b Falls from ladders Falling materials Broken bones Cuts and bruises 6 6 36 Ladders will be inspected and tagged by a competent person. Ladders shall be footed at all times. Coils of wire shall be left at ground level and a section of uncoiled wire shall be passed up to person securing the wire to the post. Ladders shall be locked securely or removed from site when not in use. Ensure three points of contact when climbing ladders. 6 2 12 Adequately Controlled Risk 20 Fuelling & Oiling Plant 20 Hazardous chemicals Spillage Flammable chemicals Damage to Environment Fire Personal Injury / Illness Property damage Explosion 6 4 24 Selection and use of appropriate PPE Use fuel nozzles that automaticallyshut-offthe flow of fuel when tank is full. Keep a spill kit near fuel and oil storage areas and refuelling areas. Turn off machines during refuelling Drip trays in place for all static plant to catch any nuisance leaks and drips thatmay occur. 6 2 12 Adequately Controlled Risk

- 31. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 31 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Routine servicing only permitted in PMV Environmental protective measures such as plastic sheeting in place for any mobile plantfuelling / servicing Store oil away from watercourses or surface water drains. No mixed storage Use funnels when fuelling from containers Fire extinguishers at fuel stations and on any mobile refuelling /service vehicles,AFFF foam Trained fire marshals / fire extinguisher operatives available Complete COSHH assessmentfor all fuels and oils Complywith COSHH assessment MSDS with stores /PMV / HSE / Env team / clinic Training & Supervision Eye wash stations First Aid Emergencyphone numbers at hand. Safe disposal ofany contaminated ground Fuel tanks to be double skinned or bunded 21 Hazardous Substances 21 Hazardous substances Flammable chemicals Spillages . Damage to Environment Fire Personal Injury / Illness Property damage 6 6 36 MSDS reviewed for all substances and COSHH assessments produced for any with adverse health affects Spill kits and eye wash kits to be available with personnel trained in their use Adequate fire precautions available Trained fire marshals / fire extinguisher operatives available Selection and use of appropriate PPE, as per COSHH assessment 6 2 12 Adequately Controlled Risk

- 32. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 32 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk MSDS’s available at work locations, to include HSE / Env. / Clinic / PMV / Stores Suitable bunded storage facilities or drip trays available for all hazardous chemicals All workers fully briefed as to requirements of COSHH assessments Use, storage & disposal in line with COSHH assessment No mixed storage of hazardous chemicals First aid & Eye wash nearby All container to have labels identifying substance Store personnel will know the hazards associated with items they dispense No decanting of hazardous and flammable substances into plastic bottles or containers Store person will be responsible to issue the necessary PPE with any hazardous substances. 22 Heat What Is Heat Stress? It's a signal that says the body is having difficulty maintaining its narrow temperature range. The heart pumps faster, blood is diverted from internal organs to the skin, breathing rate increases, sweating increases, all in an attempt to transfer more heat to the outside air and cool the skin by evaporation of sweat. If the body can't keep up then the person suffers effects ranging from heat cramps to heat exhaustion, and finally to heat stroke. 22a Thermal Heat Stress 4 4 16 Provision of drinking water for all work 4 2 8 Trivial risk

- 33. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 33 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Radiation Heat Stroke Fatigue Dehydration Collapse locations Provision of electrolyte replacement additives for drinking water supplies Provide shaded rest areas for all work locations ( with fans / AC’s where poss. ) HSE training department - Heat stress awareness campaign Poster campaigns Regular Tool box talks ref: heat stress Toilets to have urine colour charts posted to aid self assessment of dehydration levels Monitoring of operatives by supervisors for signs of heat stress and sweat rash. Adherence to Summer working hours regulations Planning of critical tasks in cooler conditions Provision of fans / AC’s in work areas as appropriate Job rotation Provision of canopy’s for exposed work areas Provision of suitable PPE Availability and awareness of First Aiders 22b UV Radiation Sunburn Skin ageing Premature cancer Eye strain Arc eye ( welders) 6 4 24 Selection and use of appropriate PPE ( welding masks etc ) Training & Supervision Full length overalls 6 2 12 Adequately Controlled

- 34. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 34 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 23 Hydrostatic Testing of Pressure Mains 23 Pipe Testing High pressure water that may cause pipe bursting and cause injuries to persons 4 6 24 Arrange exclusion zones around the areas of testing Insure only authorized persons are in the exclusion zone PPE Only qualified and competent persons conducting the tests Pressure testing permit system in place. Erect warning signage. 4 2 8 Trivial Risk 24 Joint Sealing with Hot Bitumen 24 Hot Material & Equipment Burns to skin & eyes 6 6 36 Use Bitumen Boiler – trained operatives only Use Bitumen Bucket –trained operatives only Wear heat resistant Gauntlets Wear heat resistant Boots Wear protective eye wear Job rotation to prevent heat related disorders Exclusion zone around the hot bitumen work Availability of first aiders and cool water to flush affected area in the event of burn injury Comply with COSHH assessment requirements Tool box talks Cotton coveralls to be used with hot bitumen not nylon. 6 2 12 Adequately Controlled Risk 25 Lorry Hiab 25a Hiab Lorry overturning Personal injury Property damage 6 4 24 Lorry set up on firm and level ground Outriggers fully deployed Load pads under all outriggers 6 2 12 Adequately Controlled Risk

- 35. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 35 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Hiab has valid 3rd party inspection certification. PMV inspection prior to mobilisation Licensed operator Selection of correct crane for task ( SWL etc ). Weights of loads known before lifting Exclusion zones created around lifting operations Training Check for drains etc before placing out- riggers. 25b Failure of lifting equipment Personal Injury Property damage 6 4 24 All lifting equipment shall be 3rd party inspected and certified as fit for purpose, All areas of lifting operations shall be adequately lit Operators to have valid licenses All lift accessories shall be 3rd party inspected, certified and comply with CCC /TAV JV colour coding scheme for the period 6 2 12 Adequately Controlled Risk 25c Equipment & Material Handling Personal Injury Property damage 6 4 24 All equipment will be stored, handled in a safe and proper manner. Offloading and storage will be properly controlled / supervised at all times. Tag lines will be used to control equipment during loading and offloading. Personnel will be properly trained in safe methods of Equipment handling including the danger of pinch points Erection areas will be identified and 6 2 12 Adequately Controlled Risk

- 36. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 36 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk unauthorized entry will be controlled by use of barriers, warning signs and close supervision. Appropriate personnel protective equipment will be worn at all times. Personnel will be reminded of risks through tool box talks. Period colour coded equipment. 26 Lorries Tippers & Trailers 26a Working at height whilst Sheeting and unsheeting of lorries Falls, injuries 8 6 48 Lorries with powered sheeting/ unsheeting are preferred Lorries shall park in a safe place and on even flat ground before sheeting/unsheeting Proper access ladders shall be provided for manual sheeting Sheeting & unsheeting will be done by 2 persons, one on each side of the lorry Banksman shall be available during the sheeting/ unsheeting 8 2 12 Adequately controlled 26b Mobile phones Reduced attention whilst driving leading to accidents 8 6 48 No Mobile Phone shall be used whilst driving Site induction to cover use of mobile phones Ban from site for persistent offenders 8 2 12 Adequately controlled 26c Speeding Accidents 8 6 48 Speed limits on site. Adequate signage. Speed humps Speed monitoring Ban from site for persistent offenders Site induction to be delivered to all personnel entering site. 8 2 12 Adequately controlled

- 37. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 37 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 26d Overhead Electrical Cables Elocution 8 6 48 Don’t tip under overhead cables Look up for overhead cables before tipping 8 2 12 Adequately controlled 27 Manual Handling 27 Heavy loads Uneven loads Poor techniques Back strains Personal Injury Property damage 6 6 36 All staff HSE inducted Regular Tool Box Talks ref: manual handling. Mechanical aids to be used where possible. Appropriate selection of materials by procurement Dept i.e. 25kg bags of cement. Blocks to be stacked on level ground close to the work site by mechanical means. Job rotation for lifting tasks Regular breaks Consider 2 person lift No stacking above shoulder level. Carry out manual handling assessments for large loads or repetitive work Suitable clear flat area to be used for loading / unloading with restricted access. 6 4 12 Adequately Controlled Risk

- 38. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 38 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 28 MEWP ( Mobile Elevating Work Platform) 28a General hazards Injury 6 6 36 Do not exceed lifting capacity of MEWP Only carry materials thatfit inside the basket Trained and competentoperators 6 2 12 Adequately Controlled Risk 28b Persons Falling from height Personal Injury 6 6 36 All operators to have valid 3rd party certification All operators to wear full body harnesses with double lanyards Equipment to have secure working platform / man basket with appropriate guard rails & toe boards where applicable. All works shall be conducted from inside platform / basket. List of authorised operators posted on machines 6 2 12 Adequately Controlled Risk 28c Falling objects. Personal Injury Property damage 6 6 36 Exclusion zones created around working MEWP’s. Only essential tools to be taken in MEWP basket, Tools should be tethered where possible or should be stored in appropriate holders 6 2 12 Adequately Controlled Risk

- 39. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 39 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 28d Mechanical Failure Personal Injury Property damage 6 4 24 All equipment to have valid 3rd party inspection certificate All equipment to have PMV inspection before mobilisation Pre use daily inspection Planned preventative maintenance schedules Selection of appropriate MEWP as per task requirements Drivers to carry out daily / weekly inspection of MEWP, 6 2 12 Adequately Controlled Risk 28e Overturning MEWP Personal Injury Property damage 6 6 36 If fitted, out riggers fully deployed with use of load pads SWL posted on machine On unpaved areas ensure ground is compacted and stable. The correct type of MEWP to be used for the area. 6 2 12 Adequately Controlled Risk

- 40. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 40 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 29 Night-work 29a Insufficient Lighting Traffic collisions Property damage Personal Injury 8 6 48 Appropriate lighting as per Procedure for Night Works: PP727-NWP-1008. Lighting plans and night works permits to be provided by CCC /TAV JV HS&E department. Nominated person responsible per shift to ensure that all lighting is compliant with OAMC requirements Tower lights to be setup so the light beam shines across the runway (North to South) so as not to be a distraction to pilots on finals to landing. The max heightof ground based tower lightmasts to be limited to 13m. Lighting established on raised bridge decks to be approved by OAMC Lights to have welded restrictors to ensure the light beam is downwards facing. Lighting control will be via liaison with the OAMC Light Towers erected on firm / level ground A PMV mechanic will be available for maintenance work. Safety cover Emergency contact #’s posted. Inspection by supervisor Vehicular access route to be adequately signposted and illuminated. 8 2 16 Adequately Controlled Risk 29b Lighting Nuisance to public roads Risk of traffic collisions Complaints from public 8 6 48 All lighting beams shall be suitable shaded to prevent unwanted distraction to public roads Lightbeams shall be directed down wards to flood requisite task only 8 2 16 Adequately Controlled Risk 30 Night Emergency Procedures

- 41. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 41 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 30 Emergency situations Property damage Personal injuries Disruption to project 6 4 24 Project specific emergency plan created Emergency procedure included in induction and reiterated in briefings and Tool box talks. Emergency contact details posted on site notice boards and office bulletin boards Emergency contact detail cards distributed to all supervisory staff Emergency facilities on standby ( ambulance / fire engine / clinic ) Trained First Aiders available throughout the site Trained fire wardens available throughout the site Fire points / first aid boxes available throughout the site Incident control room established at MC 1 offices Duty Incident Controller Rota established Scheduled emergency drills Liaison with civilian emergency services 6 2 12 Adequately Controlled Risk 31 Noise High levels 31 High Noise levels Threshold shift Noise induced hearing loss Tinnitus Miscommunications 4 6 24 Monitoring of noise levels and signs placed in high noise areas. Provision of sound screens where appropriate to mitigate high noise levels generated by plant / machinery Creation of high noise area exclusion zones Availability of suitable Hearing protection as required Mandatory PPE use for noise levels above 85 4 2 8 Trivial Risk

- 42. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 42 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk dB. 32 Overhead Cables Electrical 32 a Electricity Contact with cables Burns Electrocution Fatality Property damage Disruption to utility services 8 6 48 Create fixed barrier exclusion zones & traffic marshalling zones with appropriate signage Erect goal posts with cross bars for passing under ( constructed of non conductive materials ) When working underneath banksman to control plant movements Overhead power lines identified at earliest possible time Power Company contracted to establish voltage, height and safety clearance Where possible, overhead lines de-energised or relocated prior to any works Hazards identified by warning signs / notices, goal posts where necessary Inform all site personnel of danger and ensure a safe system of work is adopted Provide adequate / competent supervision All temporary structures in vicinity to be suitably earthed against possibility of arcing caused by overhead cables Operate Permit to Work. 8 2 16 Adequately controlled risk 32 b Poor Lighting Inability to discern power lines 6 4 24 All works in proximity to overhead lines will be suspended unless approved task lighting and adequate supervision is provided 6 2 12 Adequately Controlled Risk 32 c Adverse weather Increased risk of atmospheric 6 4 24 Works suspended as dictated by HSE department eg: during electrical storms etc 6 2 12 Adequately Controlled Risk

- 43. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 43 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk conductivity and arcing Exclusion zones widened in humid conditions 33 Paving Bituminous with Machine & Milling 33a Struck or rolled over by Lorries. Trapping. Crushing Broken limbs. Fatality 8 6 48 Banksman to control reversing lorries Drivers to hold valid licence Correct PPE i.e. safety boots, gloves, hard hats. Traffic calming measures shall be implemented as appropriate A flagman will be in attendance when required to guide vehicles safely into and out of the site All drivers must have an appropriate license for the particular piece of plant they are using Exclusion zones created around work area Roads closed and diverted as appropriate Posting of suitable warning signage 8 2 16 Adequately Controlled Risk 33b Hazardous chemicals Contact Burns Skin irritation 6 6 36 MSDS and COSHH assessments to be produced, followed and submitted to the Engineer for all hazardous materials to be used Correct PPE to be worn when using hazardous substances, as per COSHH assessment 6 2 12 Adequately Controlled Risk 33c Milling Machines Injury 6 6 36 Trained and Experience driver Banksman to control reversing. 6 2 12 Adequately Controlled Risk

- 44. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 44 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 34 Pipe-Jacking 34a Excavation Slips, trips & falls Serious Injury 6 6 36 Follow good housekeeping at site Remove rocks and debris from the area Follow method of statements 6 2 12 Adequately Controlled Risk 34b Noise Occupational illness 6 6 36 Proper Maintenance of Vehicle and Equipment Use ear protection 6 2 12 Adequately Controlled Risk 34c Damage to Utilities Property Damage 6 6 36 carry out survey of the area before work Install "goal Post" to prevent machines hitting overhead lines. Certified / Qualified operators to Operate the equipment Manual excavation were mechanical excavation is not practical, 6 2 12 Adequately Controlled Risk 34d Persons being struck by plant or other vehicles Serious Injury / Death 6 6 36 A dedicated Flag man at all times lag man must wear reflective vest Operators must not use mobile phones while operating machines People on foot must be kept clear of the area. 6 2 12 Adequately Controlled Risk 34e Persons Falling in to pits Serious Injury 6 6 36 Barricade & put signage in trenched area Prevent access to unauthorised people Install "STOP" blocks if necessary Ensure ladder and life line for rescue operation Ensure standby vehicle & trained person at site always for emergency. 6 2 12 Adequately Controlled Risk 34f Vehicle Equipment /Materials falling into pits (Pipe, sand Etc.) Property Damage 6 6 36 Do not park vehicle near trench Do not store excavated materials close to the trench Ensure pipes are chocked & kept 1.5mtrs from trench 6 2 12 Adequately Controlled Risk

- 45. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 45 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 34g Collapse of Pit walls or sides Injury 6 6 36 Ensure trench walls are well supported, use shoring if necessary Slope sides when excavating in sand / loose soil The excavation must be inspected daily, before work start, by a competent person. 6 2 12 Adequately Controlled Risk 34h Hazardous fume accumulation in pits Serious Injury/death 6 6 36 Do not use petrol / Diesel Engines in trenches- exhaust gases can accumulate. 6 2 12 Adequately Controlled Risk 35 Pinch Points 35 Pinch Points Hand Injuries Body Injuries 6 6 36 Keep workplace clean & tidy Wear gloves Never tamper with machine guards Care when handling equipment & materials Know how to turn off machinery in an emergency Don’t wear loose cloths or jewellery when working near machines 6 2 12 Adequately Controlled Risk 36 Plant , Equipment & Plant Operators 36 Plant & Plant Operators Injury Property Damage 6 4 24 All plant to be operated by suitably licensed and competent operators. All reversing vehicles to be controlled by a trained banksman All mobile plant to have audible reversing alarm Blind spots to be mitigated by appropriate mirrors. 6 2 12 Adequately Controlled Risk

- 46. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 46 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Site driving rules enforced. All necessary lights should be in place on vehicles including orange flashing beckons and should be used at all times as well as being regularly inspected. Vehicle Lights, windows and mirrors shall be cleaned regularly to ensure a clear view. Exclusion zones created around working plant PPE, specific to night works i.e. clear lens glasses. Operators to be trained, competent and hold current Omani Licences. Stationary plant to have drip trays. Emergency procedures in place 37 Plant Repairs, Maintenance, Assembling & Dismantling 37 Electrocution Injury 6 4 24 Provide access Task lighting Trained & competent fitters Electrical cables to be insulated Use correct tools Exclusion zones created around work area Stationary plant to have drip trays. 6 2 12 Adequately Controlled Risk 38 Plant Collision 38 Collision with other Injury 6 4 24 Banksman to guide and coordinate the 6 2 12 Adequately Controlled

- 47. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 47 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk plant Damage movements of plant items working in close proximity and reversing plant Vehicles not to be parked in swing area of cranes or excavators etc. Risk Collision with persons Injury 6 4 24 No person to stand sit or walk near working cranes excavators etc No person shall sleep or take rest under plant No unauthorised access Reversing Alarms fitted. Exclusion zones created around working plant 6 2 12 Adequately Controlled Risk 39 Reinforcement 39 Protruding steel injury 6 4 24 Starter bars covered by timbers or caps Binding wire bent away 6 2 12 Adequately Controlled Risk Cutting injury 6 4 24 Wear grinder glasses Abrasive wheel training 6 2 12 Adequately Controlled Risk 40 Road Works 40a Working on or near roads Personal Injury / Fatality 6 4 24 Suitable NOC’s shall be obtained for all road works prior to works commencing The working area should be barricaded and signs erected so that vehicle drivers are informed Drivers shall follow site driving rules at all times. Suitable lighting shall be provided for all areas of operation Traffic calming measures shall be implemented as appropriate 6 2 12 Adequately controlled risk

- 48. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 48 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 40b Collision with plant or traffic Vehicles gaining access to the site from poorly designed Traffic Management Falls into excavations or from plant Serious/fatal injuries from falls or collisions Hand, foot and eye injuries from contact with hazardous materials or flying particles 8 6 48 Correct signing/coning/barriers in place for all roadwork’s and path works. Signs made stable by sandbags Safe access for vehicles, plant and persons. Correct placing of signage shall ensure that public vehicles do not enter the work area. A flagman will be in attendance when required to guide vehicles safely into and out of the site Safe crossing of traffic lanes Fixed barriers erected around any excavations which are 2 metres or more in depth Open excavations fenced and illuminated at night with adequate signage Adequate space and sufficient time allocated to the job Noise minimised where possible High-visibility clothing worn 8 2 16 Adequately Controlled Risk 40c Realignment of Sultan Qaboos Street Step 1 - Realignment Built off line Collision with Site Injury 8 6 48 A flagman will be in attendance when required 8 2 16 Adequately

- 49. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 49 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Traffic to guide vehicles safely into and out of the site Controlled Risk Step 2a - Temporary Link Roads & widening SQS Vehicles gaining access to the site Injury Property damage 8 6 48 Signage Barriers 8 2 16 Adequately Controlled Risk Step 2b - Diverting Live Traffic Road accidents Injury 8 6 48 Signage Police escort for first cars Method Statement to give methodology and sequence. 8 2 16 Adequately Controlled Risk Step 3a - Tie-ins construction Collision with Site Traffic Injury 8 6 48 A flagman will be in attendance when required to guide vehicles safely into and out of the site 8 2 16 Adequately Controlled Risk Step 3b - Diverting Live Traffic Road accidents Injury 8 6 48 Signage Police escort for first cars 8 2 16 Adequately Controlled Risk Method Statement to give methodology and Step 4 - Removal of Redundant section of SQS sequence. Vehicles gaining access to the site Injury Property damage 8 6 48 Signage Barriers 8 2 16 Adequately Controlled Risk

- 50. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 50 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Step 5 Work in Median Traffic Accidents Injury 8 6 48 Close outside lane Night work Proper access off SQS 8 2 16 Adequately Controlled Risk 40 D Working site side of Temporary Road Barriers Struck by road vehicle crashing thru barriers Injury Property damage 8 4 24 Where possible restrict persons on the ground ( not drivers in machines) working, standing or walking within a 10m danger zone inside the barriers Warning signage Workers to be warned of the risks 8 2 16 Adequately Controlled Risk 41 Road Saw 41 Using Saw machine Cuts, injuries, eye injuries, Dust 6 4 24 Training to personnel Permit system for operators Inspect the equipment regularly Test the machine prior setting for cutting Change the blade regularly Wear Eye protection Wear Dust mask. Set up exclusion zone with barriers and signage 6 2 12 Adequately Controlled Risk 42 Scaffolding 42 Structural Personal Injury 8 6 48 Temporary works structural design. 8 2 16 Adequately

- 51. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 51 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk collapse Works at height Fall of materials Fall of persons Property Competent supervision Only essential personnel and equipment to be allowed on to raised working platforms. Regular briefings, tool box talks and night works activity briefs to be given related to working at height. All temporary working platforms ( scaffold systems ) shall be erected by trained and competent personnel All scaffold systems shall be regularly inspected by competent persons every 7 days. All scaffold systems shall display a valid (signed and dated) scaff tag to identify if safe to use Use fall arrest harnesses on scaffolding and falsework systems Use double rail fixed barriers and toe boards on leading edges. Use of suitable load rated steel life lines in absence of fixed guard rails Adequate signage and exclusion zones around temporary structures Structural design sign off before loading controlled risk 43 Steel Structures Erection 43 Works at height Adverse weather conditions Lifting operations Property damage Personal Injury 6 6 36 The work carried out in accordance with a design plan Erection carried out by competent workers Pre work briefings ref: MS and RA Training & Supervision Use of appropriate PPE 6 2 12 Adequately Controlled Risk

- 52. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 52 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk See Works at height section See Lifting operations section Trained riggers in attendance. 44 Welding & Cutting 44 a Fire and explosion Thermal Radiation Ultra-violet radiation Gases and fumes Electricity Burns Electric shock, electrocution Arc Eye Heat Disorders Respiratory problems Systemic poisoning from fumes Fire initiation and spread 6 6 36 Hot work Permits Tool Inspections Welding screens All hot works conducted by suitably trained and competent persons Proper identification and storage of acetylene and oxygen tanks All cutting / welding rigs to be fitted with flash back arrestors Provision of suitable PPE Remove all combustible materials from areas of hot works Fire watch for 30 mins post hot work activity Provision of suitable task lighting Provision of suitable ventilation ( dilution / forced ) Atmospheric testing as required ( confined space etc ) All cylinders when being transported shall have the protective guards or caps in place over the valve assemblies. They should be transported in an upright position to and from the site in the special racks provided for this purpose. Eliminate damp conditions. 6 2 12 Adequately Controlled Risk

- 53. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 53 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 44 b Grinding Operation Disc Disintegration Lacerations [may be severe, even fatal. Penetrating injuries Eye Injury 6 6 36 Use of approved suppliers Use of appropriate speed rated discs Use of task specific discs Use of correctly adjusted guards Use of suitable PPE ( body / hands / face / eyes /ears ) Trained and competent persons only to use abrasive wheels / change discs All electrical equipment to be 110V with industrial sockets Routine inspection / testing All electrical equipment colour coded Damaged equipment tagged and taken out of service All cutters and grinders regularly maintained No loose clothing worn Adequate training & supervision activities Abrasive wheel signs. Eye protection – high impact glasses at all times. Eye wash station on site 6 2 12 Adequately Controlled Risk 45 Working at Height On Scaffolding & Other Platforms 45 Persons Falling Personnel injuries 8 6 48 Temporary works structural design. Competent supervision Regular briefings, tool box talks and night works activity briefs to be given related to working at height. 8 2 16 Adequately Controlled Risk

- 54. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 54 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk All temporary working platforms ( scaffold systems ) shall be erected by trained and competent personnel All scaffold systems shall be regularly inspected by competent persons every 7 days All scaffold systems shall display a valid (signed and dated) scaff tag to identify if safe to use Use fall arrest harnesses on scaffolding and falsework systems Use double rail fixed barriers and toe boards on leading edges. Use of suitable load rated steel life lines in absence of fixed guard rails Adequate signage and exclusion zones around temporary structures Structural design sign-off before loading. Operate Permit to Work Loading platforms provided for materials & equipment Materials to be securely & safely stacked. Provide safe access and egress for personnel. Falling Objects Personnel injuries 8 6 48 Only essential personnel, materials and equipment to be allowed on to raised working platforms. Use and toe boards on leading edges. Materials to be securely & safely stacked. Erect signs re danger of falling objects All tools being used in areas with open edges must be secured using lanyards, attached to the operative, or the fixed lines. 8 2 16 Adequately Controlled Risk

- 55. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 55 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk Exclusion zones to be set up underneath working area, with use of demarcation barriers and signage. Inadequate access & egress Personnel injuries 8 6 48 Proper and safe ladder or stairs access to heights will be provided 8 2 16 Adequately Controlled Risk 46 Working On, Above or Near Water 46 Water Drowning Physical effects of swallowing contaminated water 4 6 24 Warning signs No lone working Edge protection where practical Safety lines and harnesses if edge protection is not present Lifebuoys and rescue lines Access routes free of hazards 4 2 8 Trivial Risk 47 Working Airside 47a General Injuries Property Damage 6 6 36 Site HSE Project Procedures Work Permit Systems Method Statement for Risk Activities Risk Assessments 6 2 12 Adequately controlled

- 56. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 56 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk On Site Safety Training HSE Supervision Issue of PPE Tool box Talks Works to be made knowledgeable on site specific Safety risks. COSHH Assessments On site Medical Clinic Site Emergency Response Plan Site Health, Safety & Environmental Plan First Aid Kits available First Aiders Site Inductions for Employees Welfare Facilities Waste bins Managers must take responsibility and accountability for HSE Management Training and implement above. Welfare Facilities Emergency Contact list Emergency Contact List 47b Security Risk Bombings, Shootings. Hijacking Multiple Fatalities 4 6 24 Security Passes Check vehicles entering Airside 4 2 8 Trivial Risk 47c Breaking Navigational Aids Closure of Airport Runway 4 6 24 Fence off 4 2 8 Trivial Risk 47d Breaking underground power supply to landing Closure of airport runway Elocutions 6 6 24 Scan check for underground services Supervision Area to be visually checked for markers or physical signs of services, i.e. manholes. 6 2 12 Adequately Controlled

- 57. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 57 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk lights and IT cables Up to date drawings detailing existing services shall be obtained and checked thoroughly. OAMC shall be contacted to assess if there are services in the area and also to let them know work is going to be carried out. Obtain Dig permit from OAMC. Use of trial holes and hand excavation around known services Hand tools that are non conductive shall be used when excavating around existing services. Prior to excavation the affected area shall be surveyed with a CAT and competent person. Records of all CAT surveyed areas to be kept on file and briefed to excavation team Surveyed area clearly demarked on site Emergency contact numbers displayed on site 47e Collision with Aircraft in flight Multiple Fatalities 4 6 24 Communication with ATC Observe height limits 4 2 8 Trivial Risk 47f FODs (Foreign Object Debris) Aircraft damage Aircraft engines may get damaged 4 6 24 All FODs to be cleared after the job is done Good housekeeping 4 2 8 Trivial Risk 47g Noise Fight jets Injury to hearing 4 6 24 Issue Ear protection 4 2 8 Trivial Risk 47h DUST Source of emissions from dust/particulates during leveling, scraping, and earth moving operations Reduced visibility Due to increased emissions, impacts on human health within the site and neighboring areas 4 6 24 Regular water spraying of unpaved and sweeping of paved roads to minimize dust and remove mud Sheeting vehicles carrying dusty materials to prevent materials being blown from the vehicle whilst travelling Reducing the quantity of dusty materials 4 2 8 Trivial Risk

- 58. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 58 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk via traffic movements to and from site. stored on site or covering stored material to minimize the amount of dust being blown 47i Mud Control Vehicles exiting the work site may carry mud onto adjacent roads Road Contamination Slips 4 6 24 Vehicles going from the work site onto paved roads must be free of excessive mud. 4 2 8 Trivial Risk 47j Moving Plant Injuries Collisions Property Damage 6 6 36 Banksman to guide and coordinate the movements of plant items working in close proximity and reversing plant Vehicles not to be parked in swing area of cranes or excavators etc. No person to stand sit or walk near working cranes excavators etc No person shall sleep or take rest under plant No unauthorised access Reversing Alarms fitted. Exclusion zones created around working plant 6 2 12 Adequately Controlled 47k Birdstrike Aircraft damage Aircraft engines may get damaged 6 6 36 Don’t feed birds Remove all waste food immediately Report any birds to Airport Authority 6 2 12 Adequately Controlled 48 Operating Vibrating Hand Tools

- 59. Health & Safety Construction RISK ASSESSMENTS 96 pages Page 59 of 92 Activ ity HAZARD EFFECT RISK ANALYSIS / NO CONTROLS CONTROL MEASURES RISK ANALYSIS / WITH CONTROLS Residual Risk remarks severity likelihood risk severity likelihood risk 48a 48b Vibration Vibration White Finger Hand-Arm Vibration Syndrome (HAVS) 6 6 36 Limit exposure time i.e. actual trigger time Regular breaks Job rotation Ensure tools are used correctly and maintained. Wear gloves Oil the tool daily before use. 6 2 12 Adequately Controlled Risk Dust Eye injury Dust Inhalation 6 6 36 Wear dust mask. Wear goggles 6 2 12 Adequately Controlled Risk 49 Poor Housekeeping 49 Housekeeping Skin puncture. Dust inhalation. Material handling injuries. 6 6 36 Toolbox talks. Signs and posters. PPE issue and training. Police use of. Supervised daily by site supervisors 6 2 12 Adequately Controlled Risk 50 Working in Live Sewer Manhole (Haya Manhole # 17)