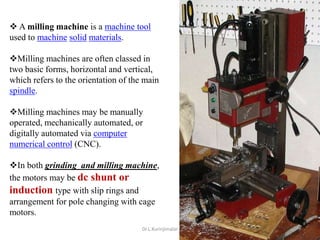

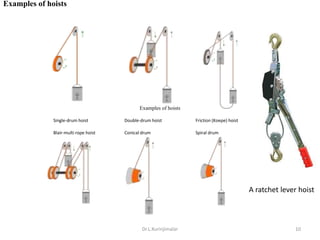

The document describes various motor drive applications in machines such as grinders, milling machines, and excavators, detailing their operational mechanisms and motor types. It covers the use of different motor types, including DC shunt, induction, and compound motors across several machine tools and processes. Additionally, the document discusses advanced motor applications like servo motors and sensors for precise control and movement.