31 NDRC operations within Excavations (Temporary Works) Risk Assessment Templates.docx

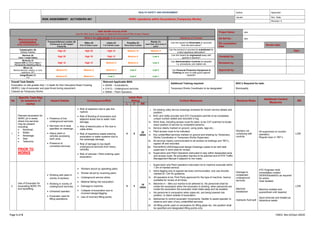

- 1. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 NDRC operations within Excavations (Temporary Works) Issued: Rev. Date: Revision: 0 Page 1 of 4 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR 1 Planned excavation for NDRC pit in areas where live services may be present including: Electrical; Water; Sewerage; Gas; Telecoms; PRIOR TO WORKS Presence of live underground services; Services not in area specified on drawings; Heavy plant or vehicles accessing work area; Presence of unmarked services; Risk of explosion due to gas line rupture; Risk of flooding of excavation and adjacent areas due to water main damage; Risk of electrocution or fire due to cable strike; Risk of hazardous waste entering excavation or water systems due to live sewerage damage; Risk of damage to low depth underground services from heavy vehicles; Risk of vehicles / Plant entering open excavation; 4 5 20 HIGH i. All existing utility service drawings reviewed for known service details and position; ii. NOC and Utility provider and ATC Excavation permits to be completed, unique number added and recorded in log; iii. Work Area, including access route for plant, to be CAT scanned to locate exact position of service by competent persons; iv. Service clearly marked on ground, using posts, tags etc.; v. Plant access route to be indicated; vi. Any unidentified services marked on ground and drawing by Temporary Works Coordinator or Temporary Works Supervisor; vii. All services clearly communicated to all workers at briefings and TBT’s, signed off and recorded; viii. Permit/NOC/JSEA/Approved design Drawings copies to be with task supervisor in work area for review; ix. Supervision and Plant Operators instructed to stay within designated area and access route; All excavation barriers to be planned and to RTA Traffic Management Manual if adjacent to live roads; Workers not complying with controls All supervision to monitor operation; Regular topic in TBT’s LOW 2 Use of Excavator for excavating NDRC Pit and backfilling Working with plant in vicinity of workers; Working in vicinity of underground services; Untrained operator; Excavator used for lifting operations; Workers struck by operating plant; Worker struck by reversing plant; Underground service strike; Material falling into excavation; Damage to machine; Collapse of excavation due to incorrect design/digging; Use of incorrect lifting points; 4 4 16 HIGH i. Supervision and Plant operators instructed not to machine excavate within 1.5m of marked service; ii. Hand digging only to expose services communicated, only use shovels marked at 1.2m for guidance; iii. All operators to be Third Party approved for the type of machine, licence available for review at all times; iv. Machine in – Men out mantra to be adhered to. No personnel shall be inside the excavation when the excavator is working, when personnel are inside the excavation the excavator shall rotate away and be isolated; v. No personnel in excavation when pipes etc. are being lowered into position, to stand outside of excavation; vi. Banksman to control excavator movements; Spotter to assist operator to observe and warn of any unidentified services; vii. All lifting points used on excavators for lifting pipes etc. into position shall be specified and designated lifting points only; Damage to undetected underground services Machine breakdown Hydraulic fluid spill ATC Engineer shall immediately contact DEWA/Etisalat/Du as required for action. Area isolated. Machine isolated and quarantined until repaired. Spoil removed and treated as hazardous waste LOW RISK SCORE CALCULATOR Use the Risk Score Calculator to Determine the Level of Risk of each Hazard What would be the CONSEQUENCE of an occurrence be? What is the LIKELIHOOD of an occurrence? Hierarchy of Controls Frequent/Almost certain (5) Continuous or will happen frequently Often (4) 6 to 12 times a year Likely (3) 1 to 5 times a year Possible (2) Once every 5 years Rarely (1) Less than once every 5 years Can the hazard be Eliminated or removed from the work place? Catastrophic (5) Multiple Fatalities High 25 High 20 High 15 Medium 10 Medium 5 Can the product or process be substituted for a less hazardous alternative? Serious (4) Class 1 single fatality High 20 High 16 High 12 Medium 8 Low 4 Can the hazard be engineered away with guards or barriers? Moderate (3) Class2 (AWI or LTI) or Class 1 Permanently disabling effects High 15 High 12 Medium 9 Medium 6 Low 3 Can Administration Controls be adopted I.e. procedures, job rotation etc. Minor (2) Medical attention needed, no work restrictions. MTI Medium10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipment & Clothing be worn to safe guard against hazards? Insignificant (1) FAI Medium10 Medium 4 Low 3 Low 2 Low 1 Project Name: xxx RA Ref No.: xxx RA compilation Date: Review date: Date: Compiled by: Reviewed by: Approved by: Overall Task Details Excavation on site greater than 1.2 depth for Non Disruptive Road Crossing (NDRC). Use of excavator and pipe thrust boring equipment Classed as Temporary Works Relevant Applicable MAS: 00246 – Excavations; 01413 – Underground services; 00940 – Plant Operators. Additional Training required: Temporary Works Coordinator to be designated NOC’s Required for task: Municipality

- 2. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 NDRC operations within Excavations (Temporary Works) Issued: Rev. Date: Revision: 0 Page 2 of 4 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR viii. Daily checks on machine undertaken prior to commencing work; 3 Excavation open in site area Excavation in working areas with live traffic movements and pedestrians; Unprotected excavation area; Excavation not to approved design; Damage to exposed existing live underground services; Trench/excavation collapse; Falling/slipping into trenches; Overturning of Truck / machinery into excavation; Incident due to poor illumination; Incident due to hazardous gas/fumes entering excavation; Collapse/damage of structures due to undermining; Difficulty rescuing injured or collapsed worker from deep excavation; 4 4 16 High i. Temporary Works Coordinator / Construction Team to ensure Permit to Excavate has been issued, communicated and signed by personnel prior to any excavation work; ii. Excavation safety buffer, protection, design and traffic signs to be to ATC Minimum Acceptable Standard, RTA Manual Chapter 3 requirements (as applicable) and DM Code of Practice -Section 9; iii. Any exposed services to be protected and adequately supported to avoid damage; iv. Any unidentified services discovered to be immediately communicated to management and work stopped; v. All spoil to be maintained at least 2m from excavation; vi. Trench boxes to be used where practicable, backfilled behind; vii. All shoring, trench sheet supports etc. to be as per approved design, following correct working procedures; viii. Temporary Works Coordinator to ensure excavation design adhered to at all times; ix. On deep excavations where a suitable ramp cannot be created, a platform with winch to be established to facilitate emergency rescue of workers; x. Provide access ladders or ramps that suitable to the size and location of excavation. Access and egress ladders/steps to be secured, every 20m on long runs, or steps dug into soil, suitably supported; xi. All excavations below 1.2m depth to be benched/battered back to MAS standards; xii. Excavation to be inspected daily with written inspection report weekly by Temporary Works Supervisor; xiii. Daily briefings to workers on working in excavations requirements by supervision; xiv. Use of stop blocks, barriers and other suitable means of protection used to prevent vehicles entering excavations, warning tape is not to be used as primary protection; xv. Where practicable, access roads and pedestrian walkways to be established away from excavations; xvi. Suitable and sufficient signage introduced to excavations; xvii. Backfilling of trenches/excavations to be undertaken as soon as possible after verification or completion of works; xviii. Excavation to be suitably illuminated during night times; xix. No changes to excavations without re-submittal of design reviewed by the TWC, NOC and Permits; Vehicle entering excavation Excavation collapse Incident due to barrier removal Emergency services called, area cleared Secure area No removal of protection barriers without prior approval from management. LOW 4 Confined space working – deep excavation for NDRC Workers required to work in confined space; Excess or lack of oxygen; Presence of Toxic gases; Ingress of water or other substances; Explosion due to build-up of gases; Sudden water ingress into excavation; Restricted emergency evacuation. 4 4 16 High i. Permit to be issued & gas monitoring undertaken if required before works commence; ii. Adequate air circulation & lighting to be maintained in work areas; iii. Equipment which may release excess oxygen or carbon monoxide gases shall not be used in confined space areas without adequate extraction; iv. Local weather forecast should be noted to watch for heavy rains which may cause flooding; v. Special consideration to be given to any hot works or work using toxic substances inside a confined space; vi. Materials to be stored well away from confined space area; vii. Top man to be appointed at the entry of the confined space area as required; viii. Workers should be physically fit and competent to enter and undertake the work in confined spaces; ix. Rescue platform to be established with tripod; Workers not adhering to requirements; Gas detector not calibrated resulting in incorrect reading Supervision to constantly monitor workers; Regular TBT’s & Trainings to be given on working Confined space; Gas detector to be calibrated to standards and manufacturers recommendations. Low

- 3. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 NDRC operations within Excavations (Temporary Works) Issued: Rev. Date: Revision: 0 Page 3 of 4 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR 5 NDRC – Thrust boring operation Use of lifting equipment to lower machine; Concrete pumping within excavation Lifting operations, fall of material and over-sailing workers; Electrical connections; 4 4 16 HIGH i. Follow RA12 – Mobile crane for lifting Ops; ii. Follow RA14 – Use of concrete pump; iii. Dewatering pump to be set up as required; iv. When excavation is complete, blinding concrete shall be cast in the base of the pit to provide stable level ground for the boring machine; v. If required, concrete thrust wall to be cast, to provide pressure plate for the machine; vi. Emergency rescue procedures to be established, with area designated for rescue tripod on deep excavations; vii. The temporary electrical supply to the borer is to be to accepted standards with correct connections, fittings and earthing, undertaken by competent electrician; viii. All members of the boring team are to be trained and experienced in the use of the equipment; ix. Consideration shall be taken regarding the removal of spoil from the boring pit; x. No guards to be removed from the equipment; xi. At no time will workers be allowed to enter pipework without correct precautions in place; xii. No lone working inside pit; Injury to worker inside pit Rescue drills to be undertaken to ensure effective rescue Low 6 Pipe electric welding inside pit Use of Arc welding equipment; Risk of fire; Risk of damage to integrity of dust protection; Risk of electric shock through equipment fault; Workers exposed to welding flash; 3 4 12 HIGH i. ATC PTW implemented; ii. Fire extinguishers and Fire watchman in area, and will maintain 1 hour fire watch after completion of work iii. All welding equipment shall be tested by a competent electrician and to standards, correct earth grounding shall be implemented; iv. All leads shall be undamaged, with correct connections fitted; v. Welder to be competent and experienced in the task; vi. Welding set raised off the ground to prevent contact with groundwater, placed outside pit if practicable; vii. If welding generator is used, drip tray to be fitted, with additional grounding added; viii. Refuelling of generator, correct fuel cans/pumps used; ix. Flash screen implemented to ensure other workers not exposed to flash inside pit; x. Welder to wear correct protection, gloves, apron etc.; Welding leads damaged Fuel spillage Quarantine welding set. Replace leads Remove contaminated soil and treat as hazardous waste Low 7. HDPE Welding inside pit Fusion Welding; Confined space; Risk of Fire or Explosion in Gaseous environments; Failure of equipment; Incorrect and insufficient welded joint causing breaking of pipe when shifting into position – risk of injury; Injury due to untrained personnel; Electric shock due to damaged wiring of equipment; Injury due to unguarded clamps and cutting blades; Risk of manual handling injuries while transporting equip Risk of burns form contact with hot parts; 3 4 12 HIGH i. Caution to be used when used inside excavations, gas testing and PTW in place; ii. All personnel trained and certificated in the use of the equipment; iii. Manufacturers protocols and operating procedures communicated; iv. Test certificates available and in-date; v. PAT test completed and equipment tagged; vi. All guards to be in place; vii. All gases to be vented and levels checked with gas meter before electro-fusion takes place; viii. Some equipment delivers up to 48V AC via the output connector and lead. The unit output power must not be energized without proper connection of the correct fitting type; ix. Avoid walking or standing on cables and ensure that the cables are safely routed; x. Where practicable mechanical lift to be used to transport the equipment at all times; Injury to worker inside pit Rescue drills to be undertaken to ensure effective rescue Low

- 4. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 NDRC operations within Excavations (Temporary Works) Issued: Rev. Date: Revision: 0 Page 4 of 4 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR Risk of injury due to incorrect fusion welding of joint resulting in injury during lifting into situ; Risk of injury through poor maintenance of welder; Risk of eye injury; Risk of damage to cables; Risk of tripping; xi. The process of Electro-fusion jointing generates heat in the fitting. Heat resistant gloves are to be used at all times when working with hot components; xii. Hands and feet to be kept clear of clamps, emergency stop switch must be functioning and within reach at all times; xiii. Ensure correct pipe alignment to avoid failure of joint with injury potential during lifting; xiv. Ensure Heat Soak time is as manufacturers requirement to avoid failure of joint during lifting; xv. Maintenance schedule to be adhered to and available for inspection; xvi. Ensure dwell time is correct to avoid joint failure; xvii. Eye protection to be worn at all times; xviii. All protective equipment to be worn at all times; 8 Maintenance of NDRC Excavation Adverse weather; Excavations open for long periods; Unapproved amendments to design; Collapse of excavation due to alterations; Damage to excavations due to incident or adverse weather; Incident due to removal of barriers 3 3 9 Med i. Excavation checked after heavy rains, severe winds etc., stand by pumps to be available as required; ii. Weekly recorded inspections undertaken; iii. Implemented warning signage maintained; iv. Housekeeping inside excavation to be maintained, all rubbish and waste material to be removed daily; Low 9 Worker exposure to direct sun (as applicable) Workers exposed to high summer temperatures; Worker ill health due to: Heat exhaustion, Heat stroke; Heat Stress. 3 4 12 High i. Summer Hour Working plan to be designed and implemented; ii. Municipality summer working hours observed and implemented (12.30pm to 3.00pm restricted in direct sunlight); iii. Workers instructed regarding working in the heat and signs of heat exhaustion etc. at Induction; iv. Recovery cool rooms established on site; v. Cool welfare areas established in all locations; vi. Cool fresh water and electrolyte supplements to be maintained in all areas; vii. Pipe welders etc. provided with localised shelters; New workers bought onto site Regular topic in Toolbox Talks Low