1. Consignment goods are goods stored at a customer's location but owned by the company. Customers can access consignment goods in their warehouse at any time.

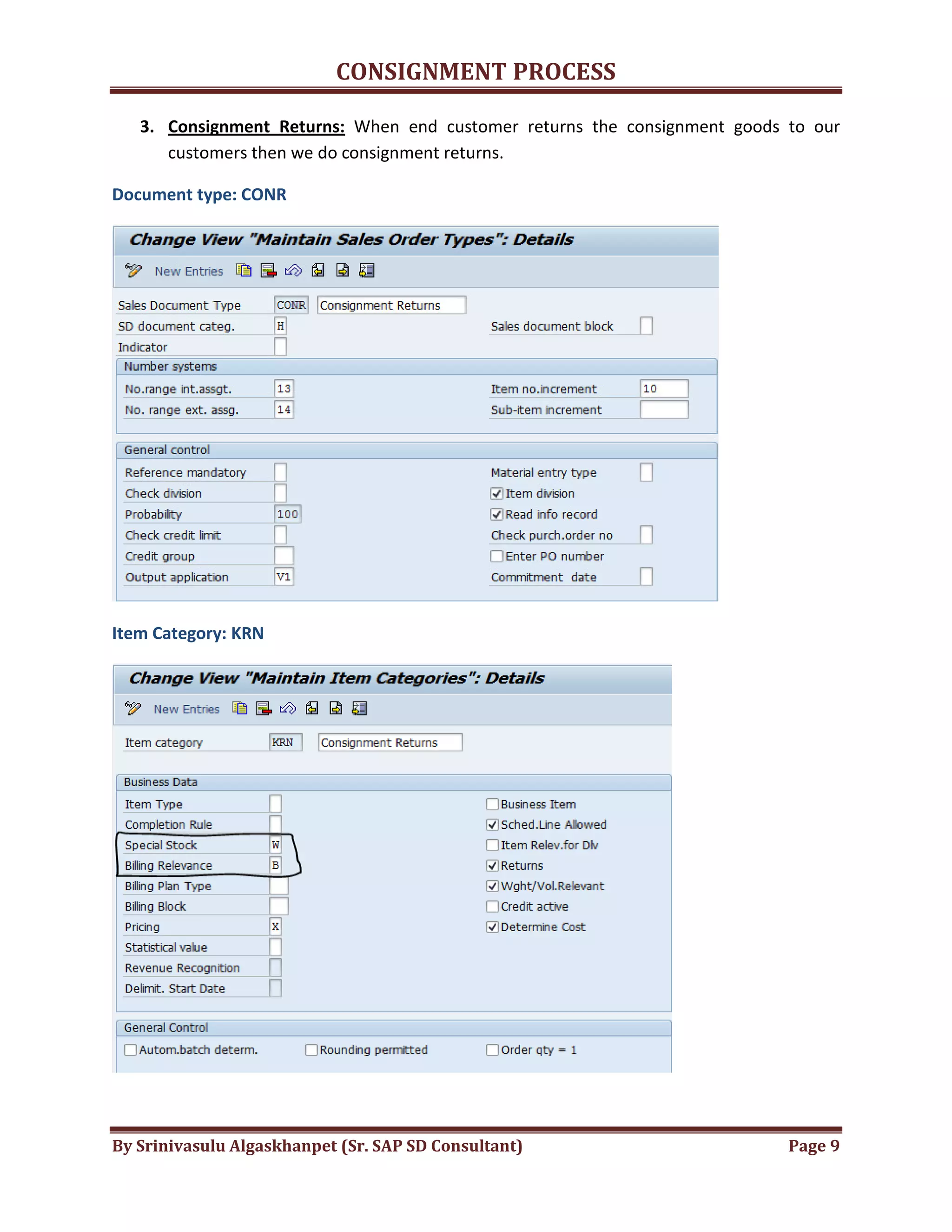

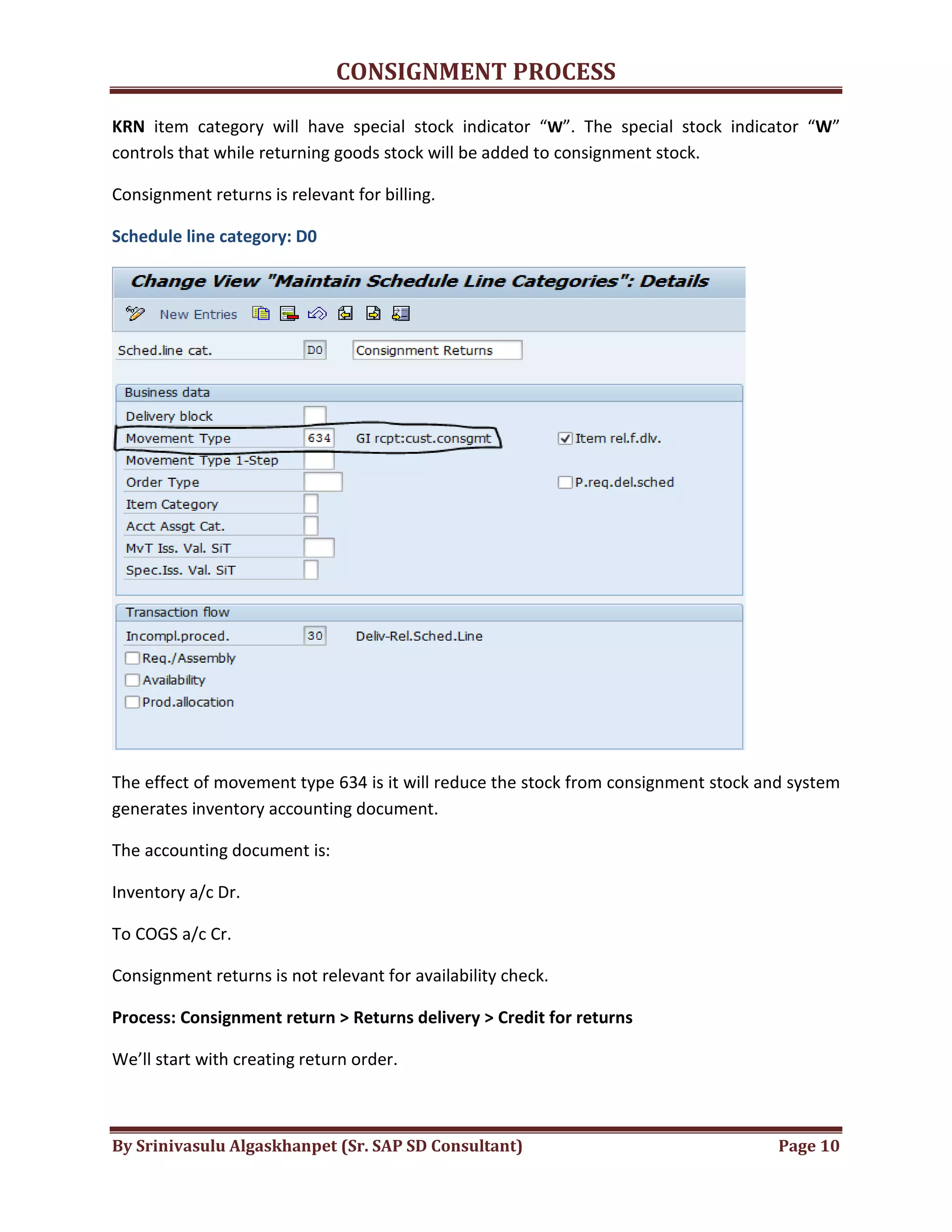

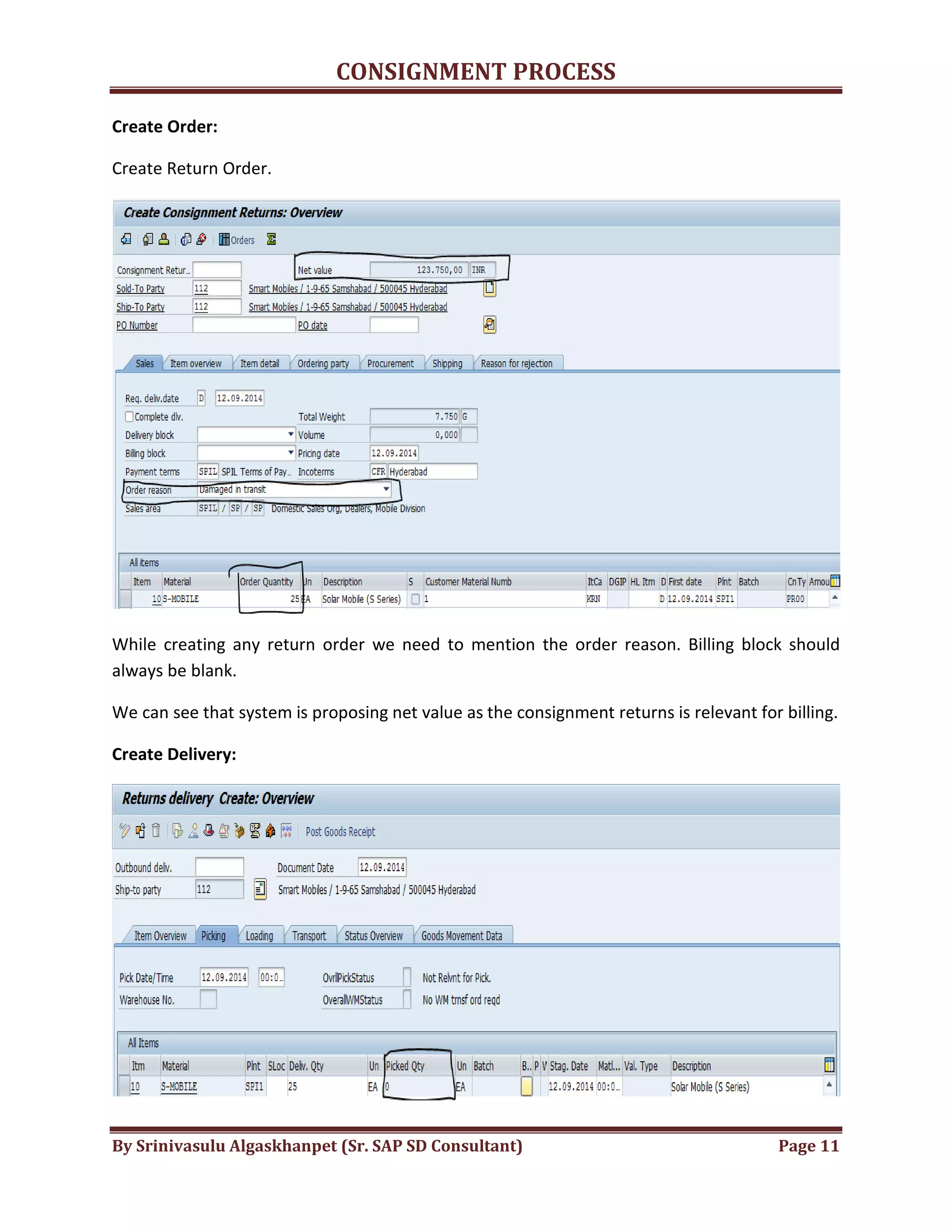

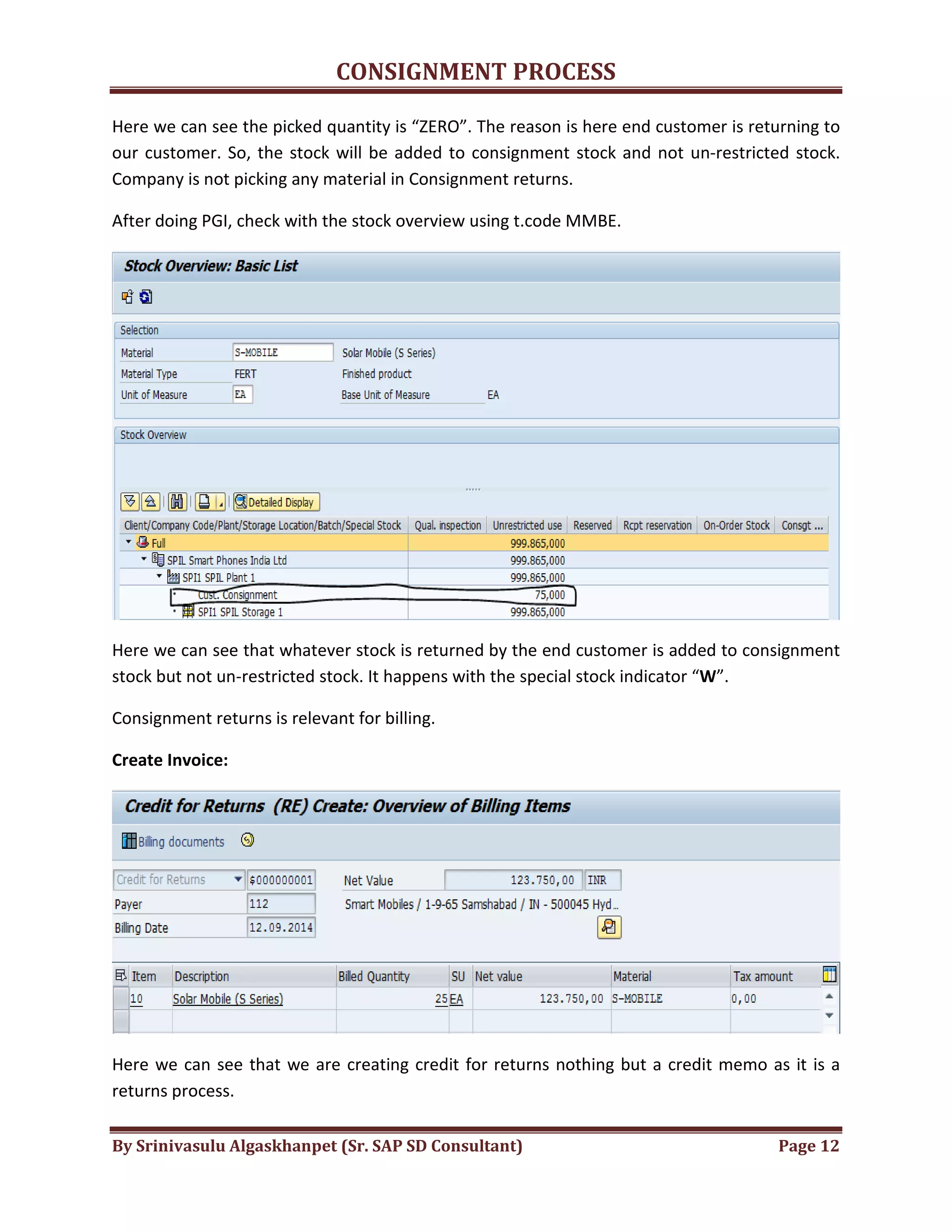

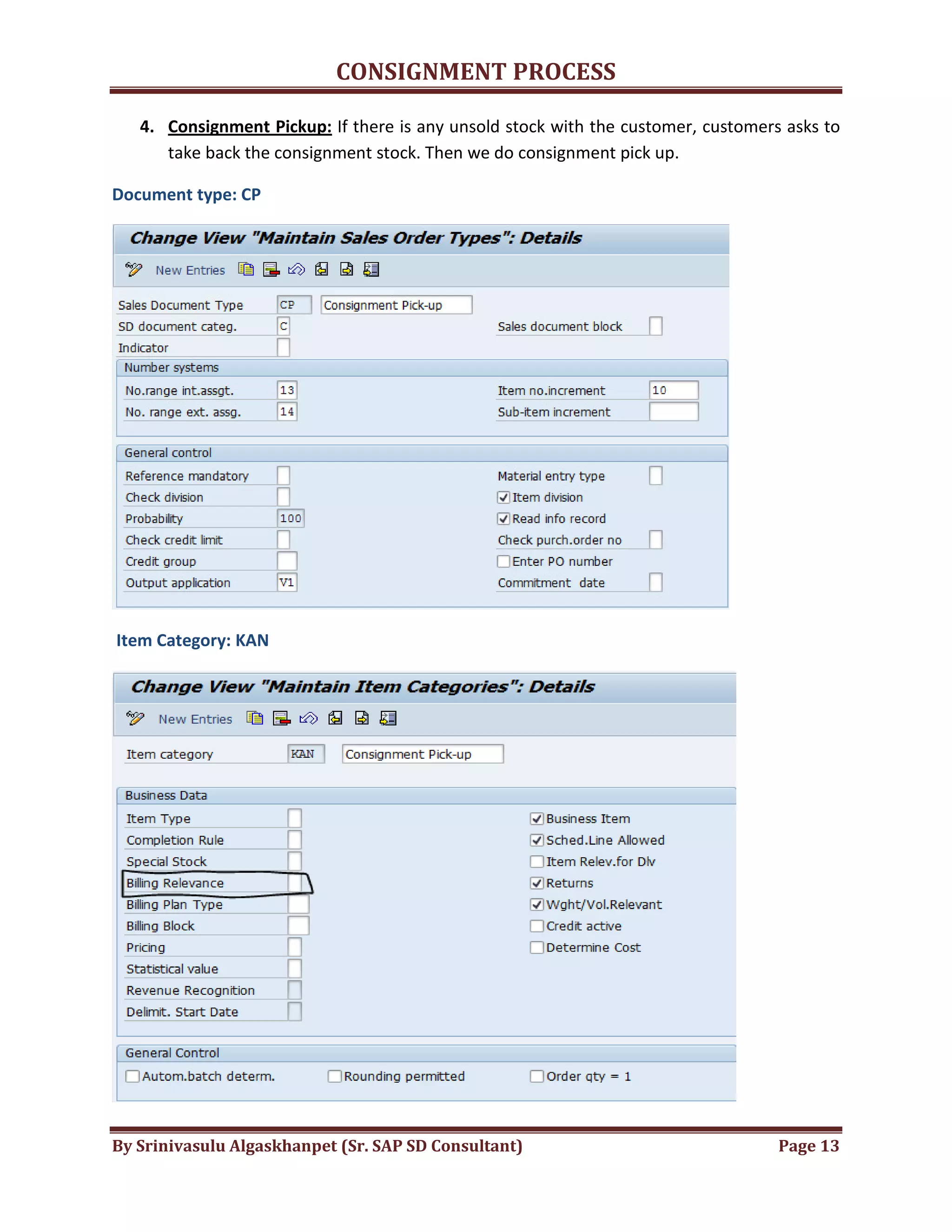

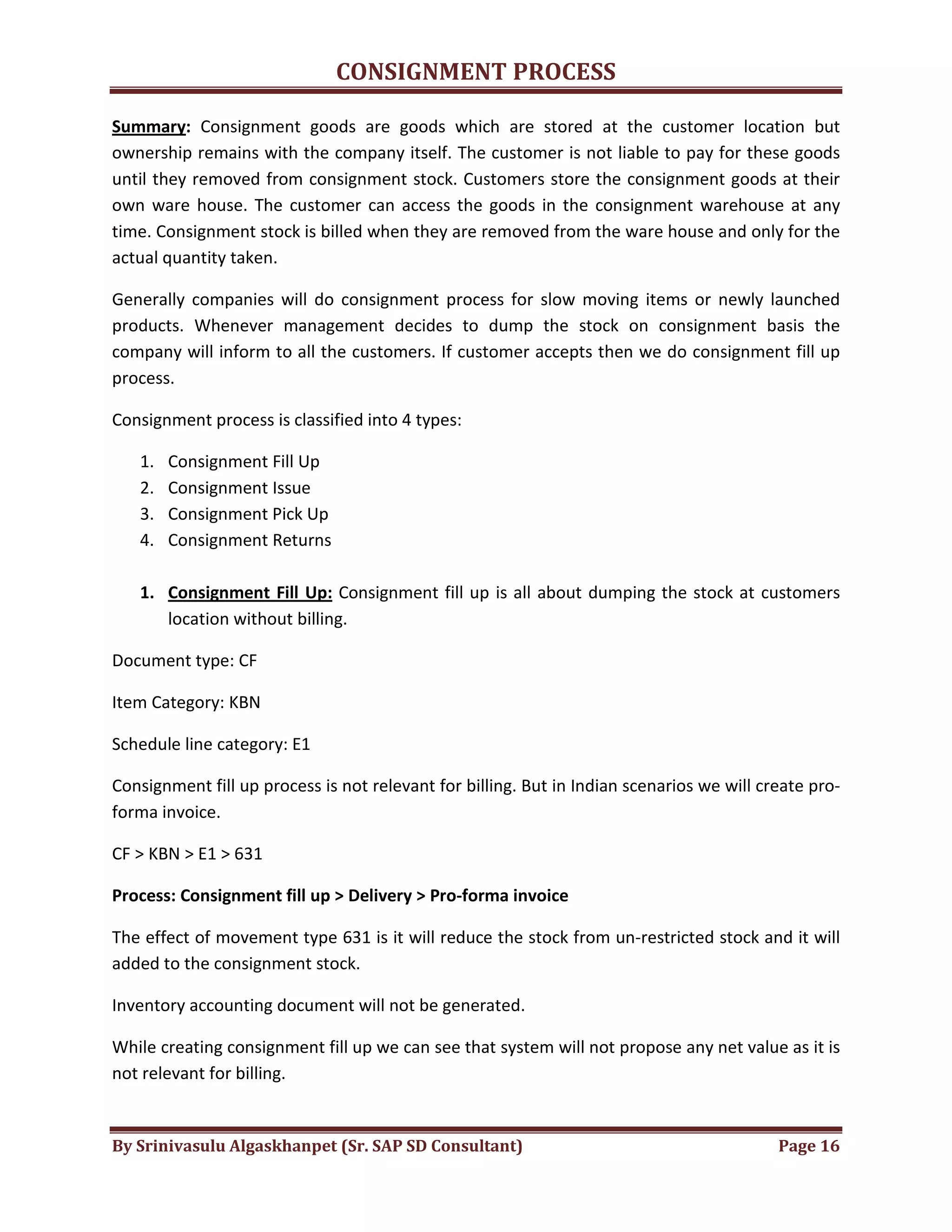

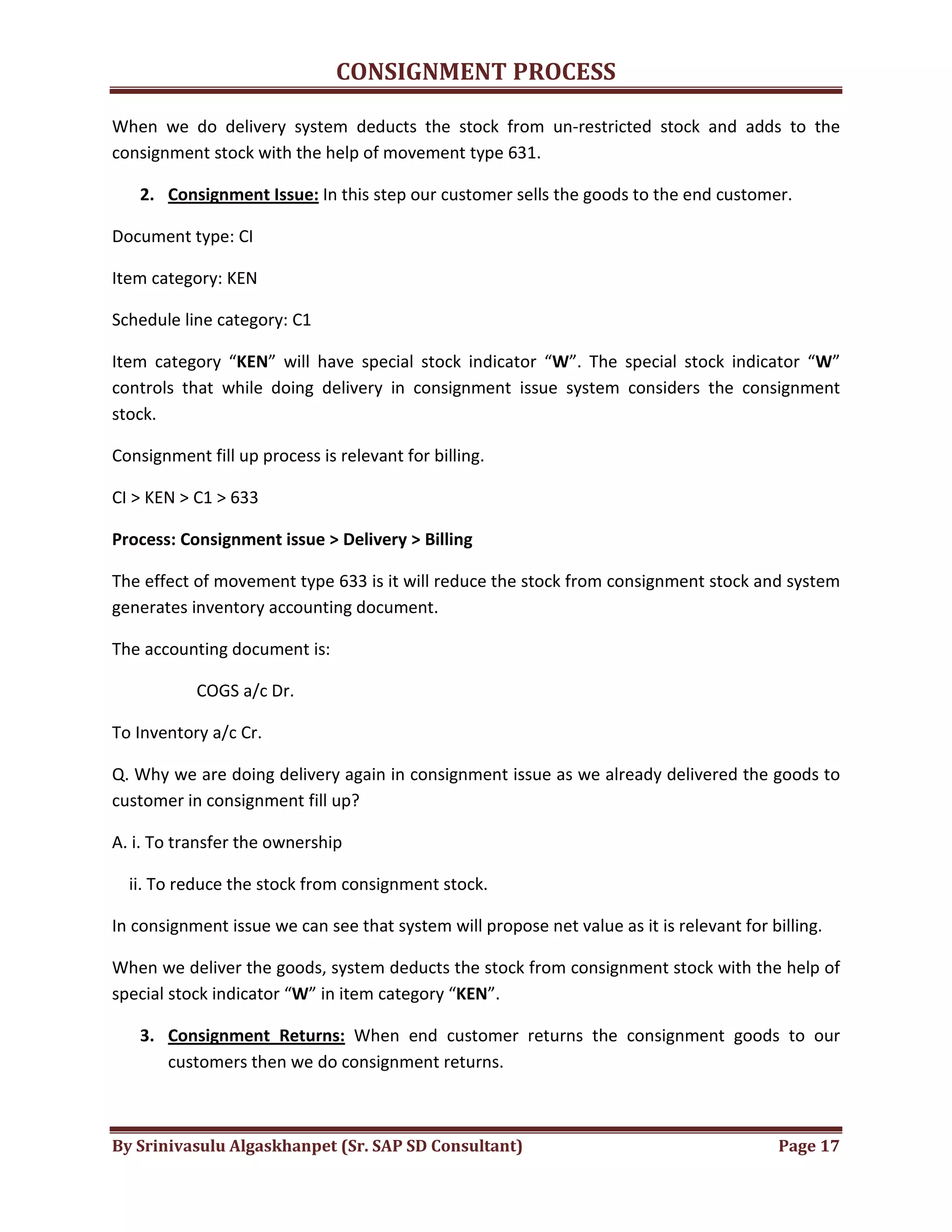

2. There are four consignment processes - Fill Up, Issue, Returns, and Pick Up. Fill Up dumps stock at customers without billing. Issue occurs when customers sell consignment goods, Returns are goods returned by customers, and Pick Up retrieves unsold stock.

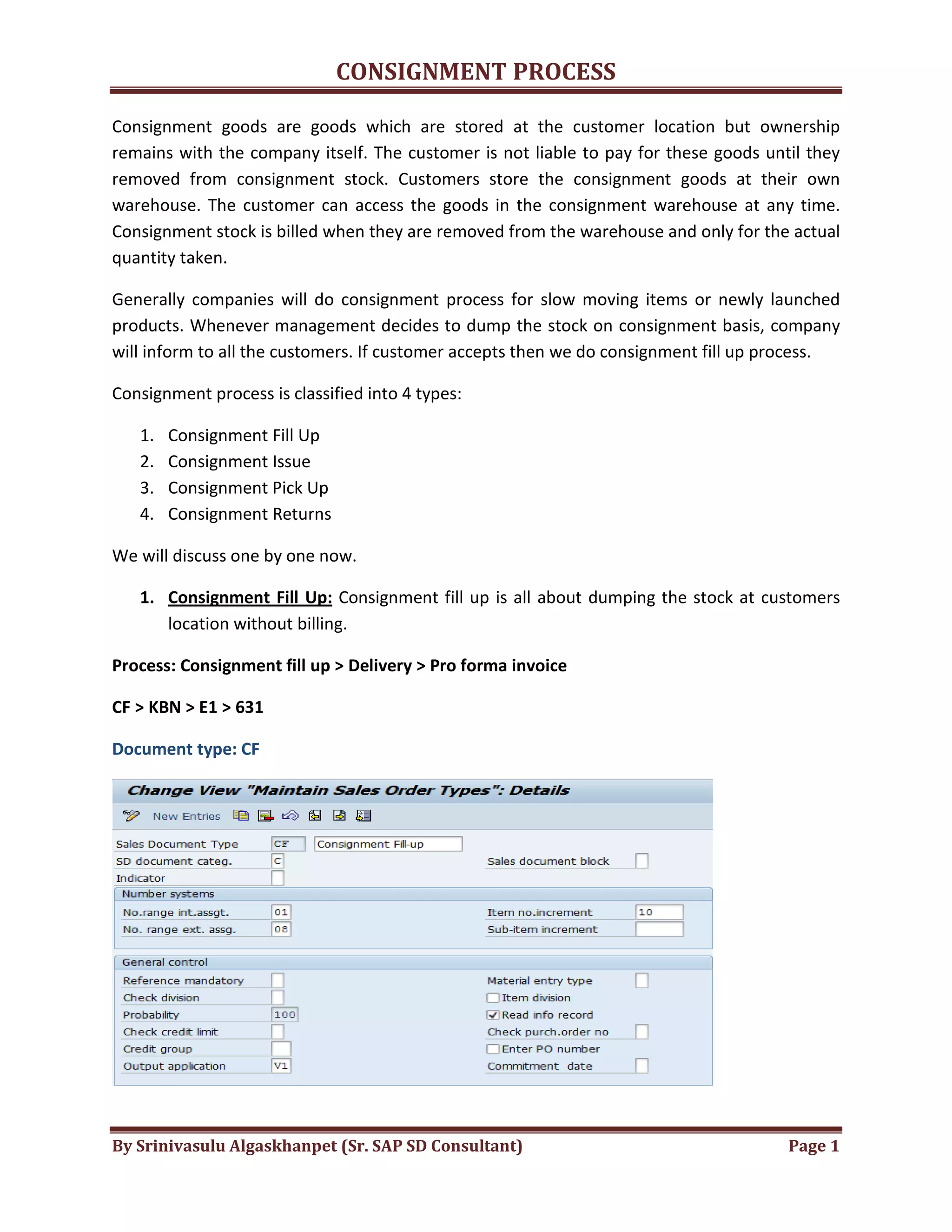

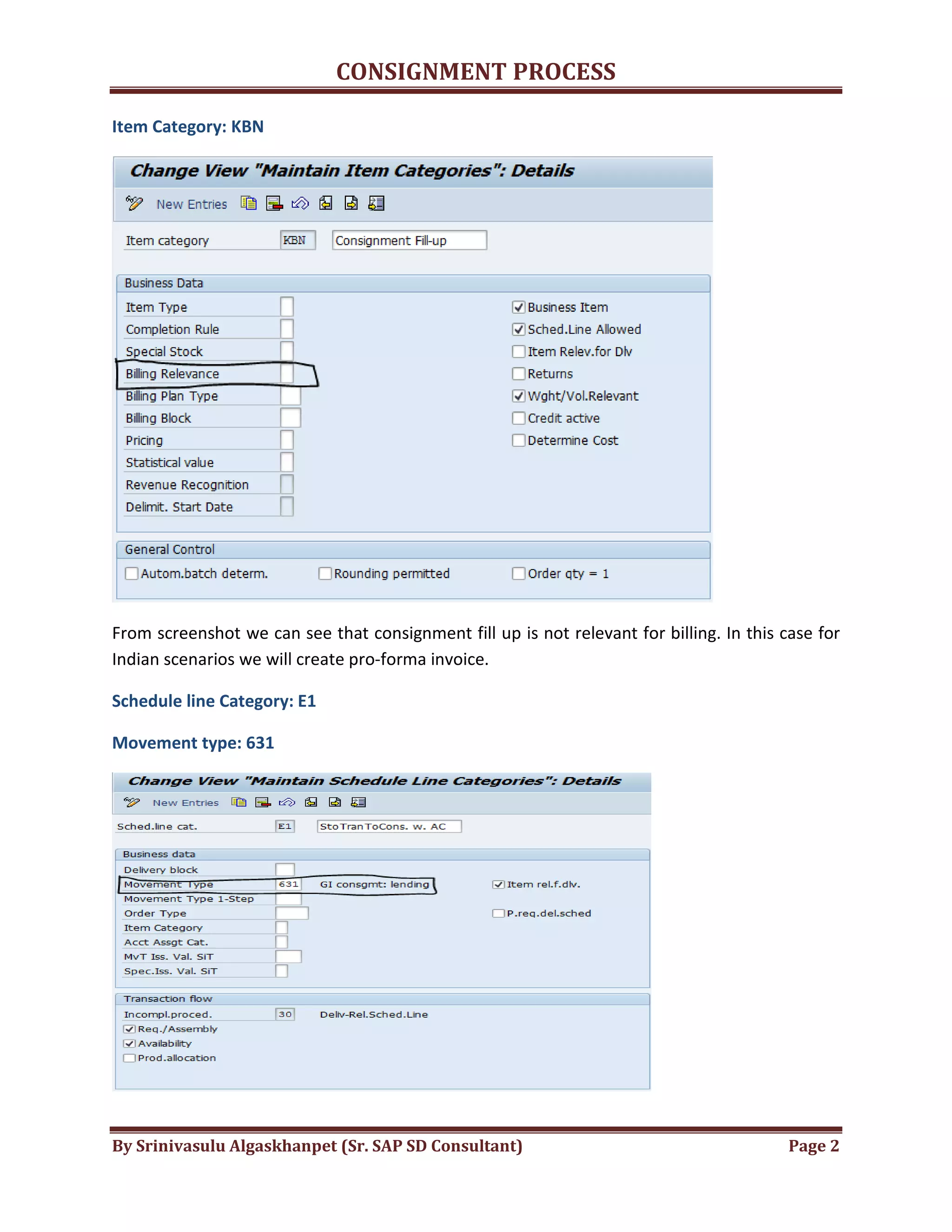

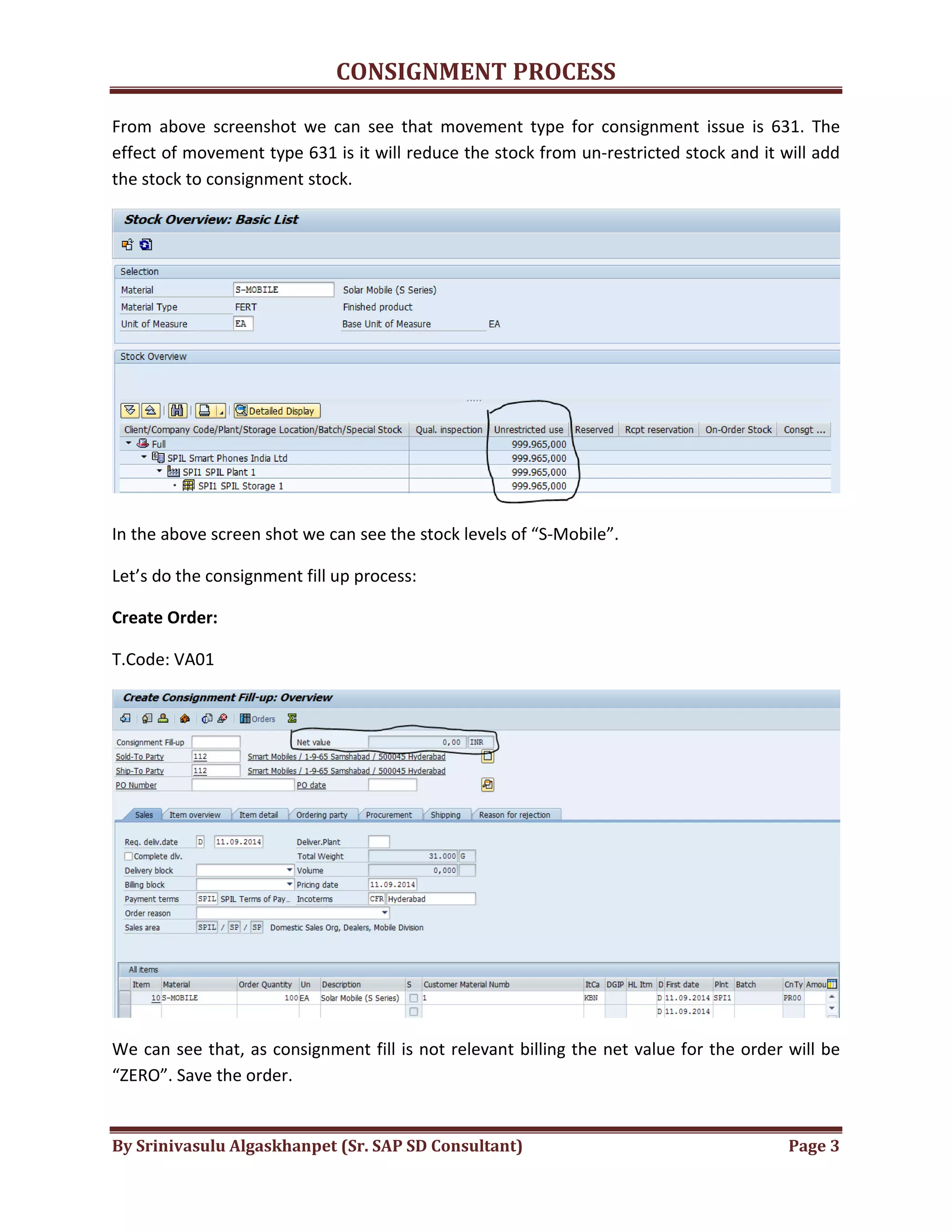

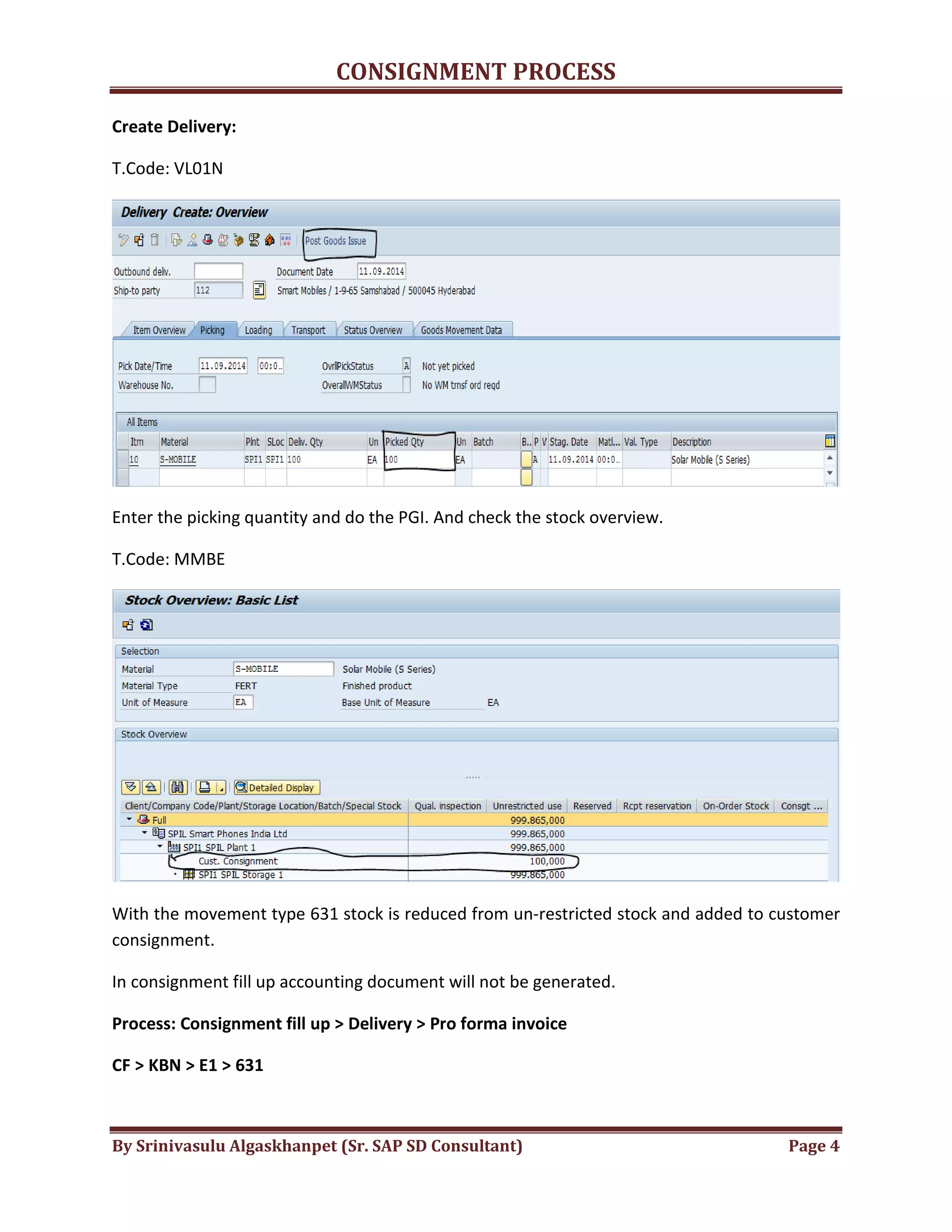

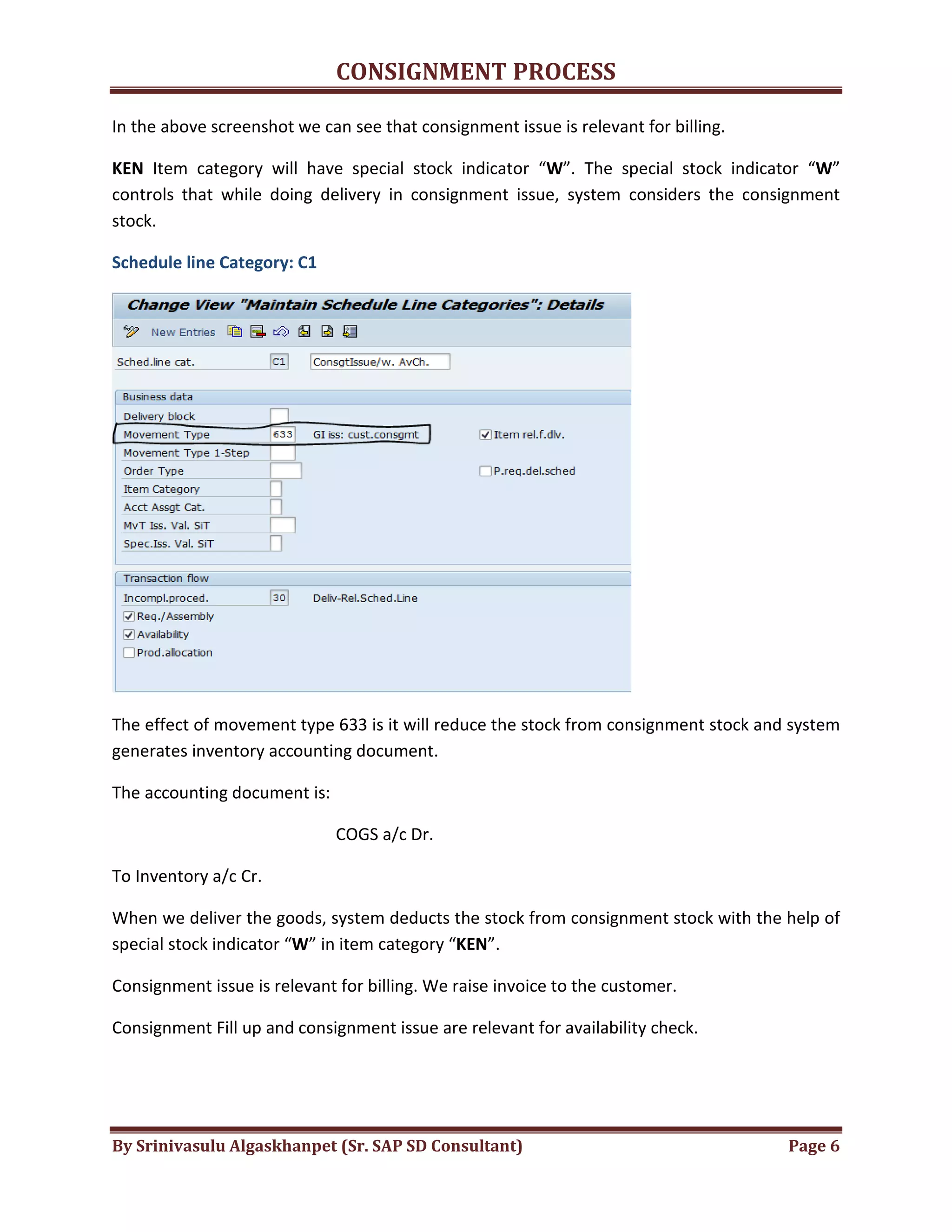

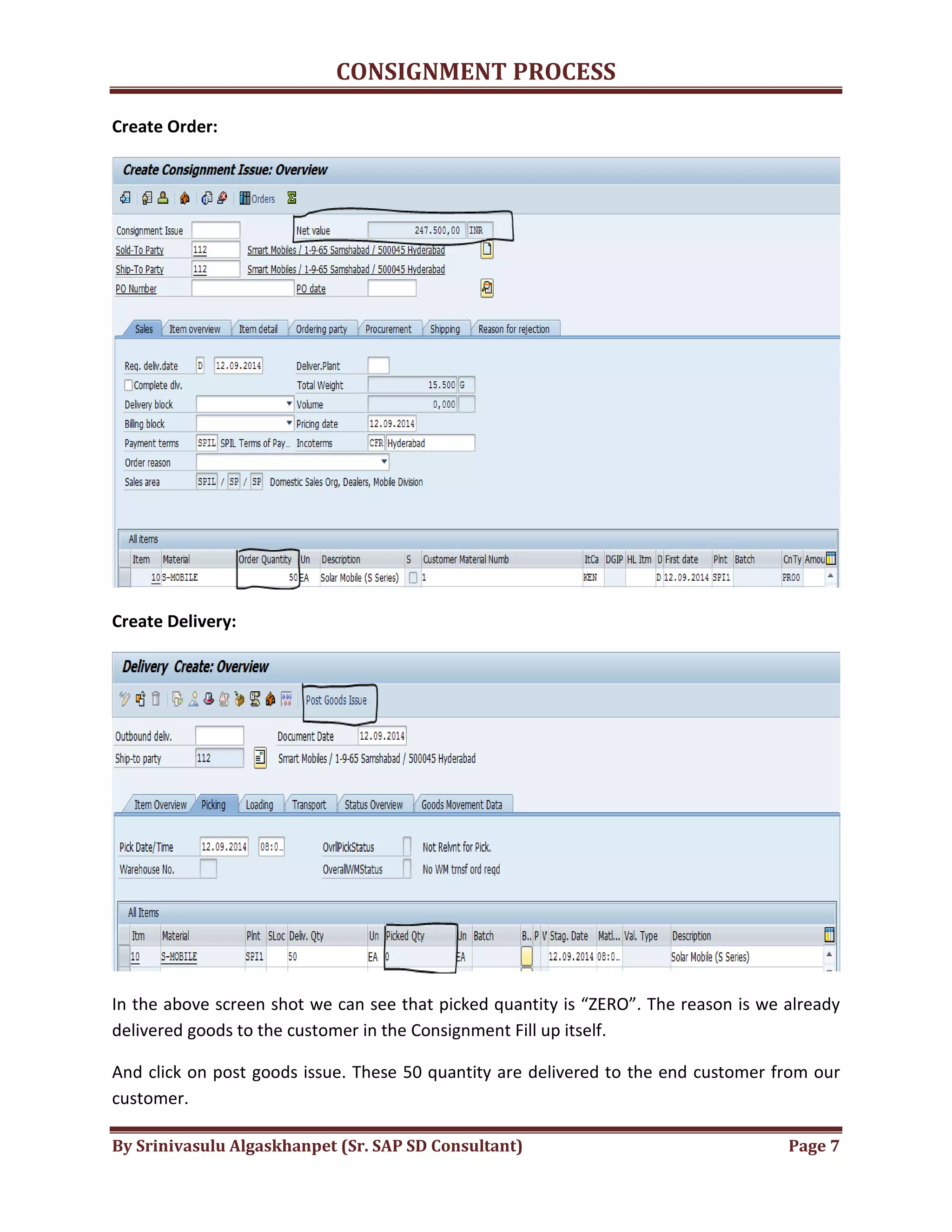

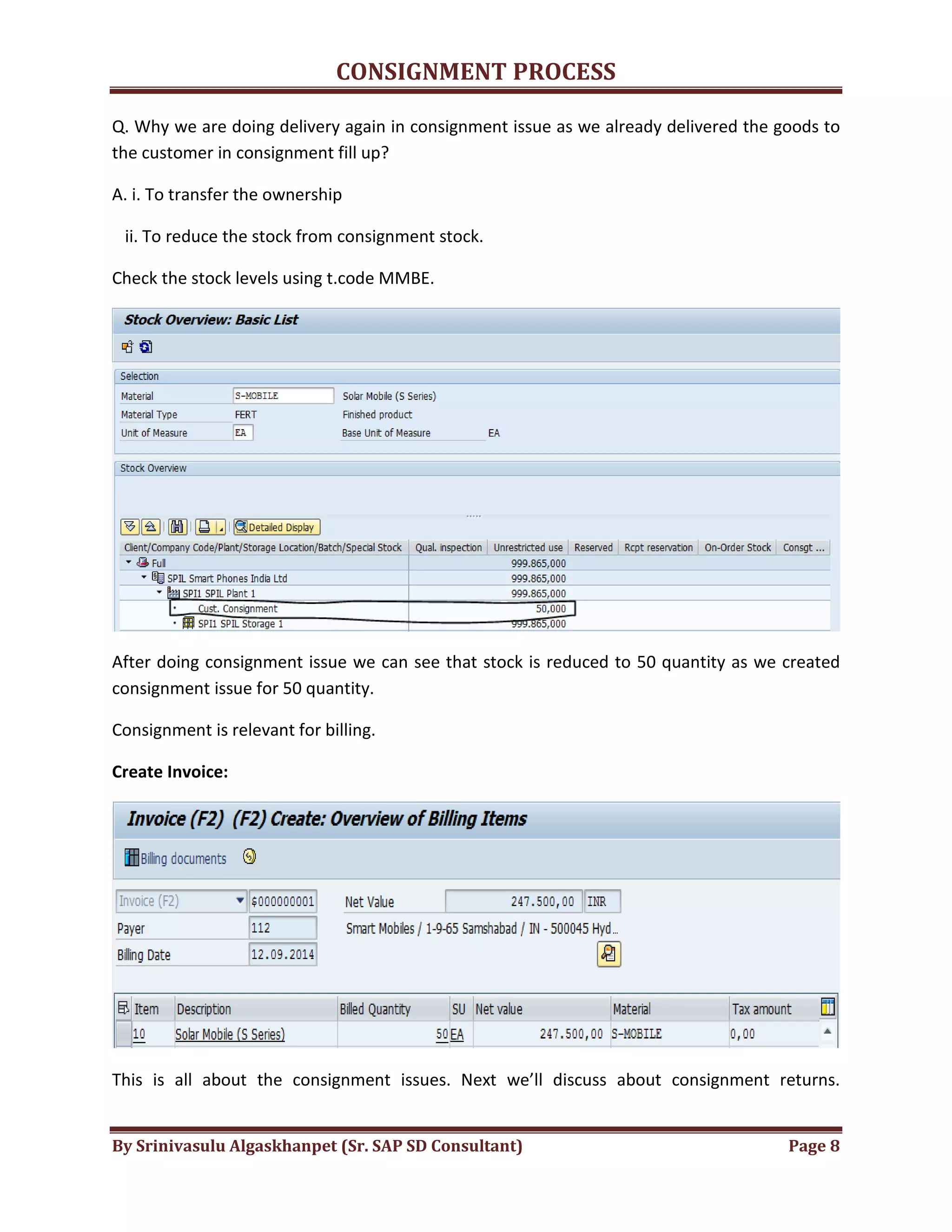

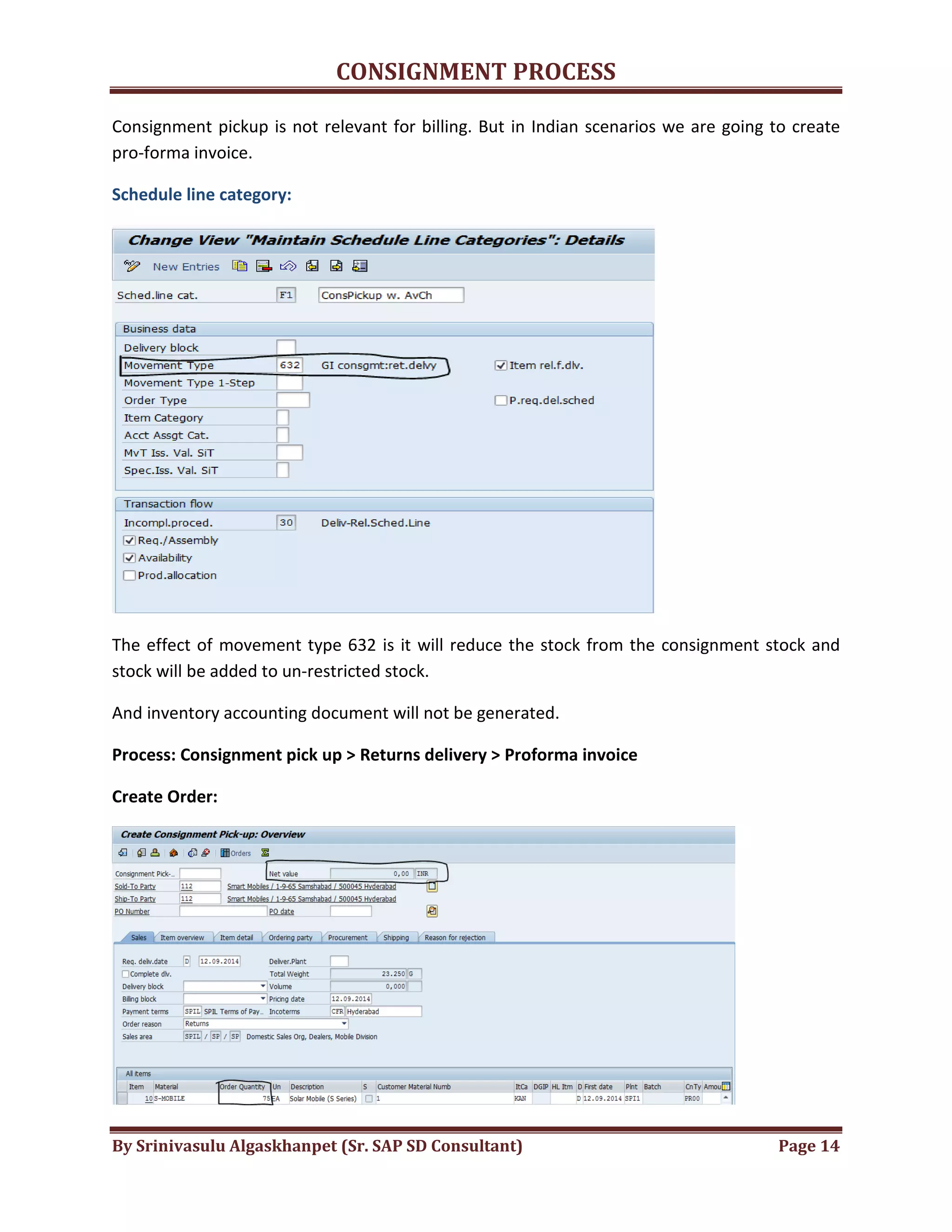

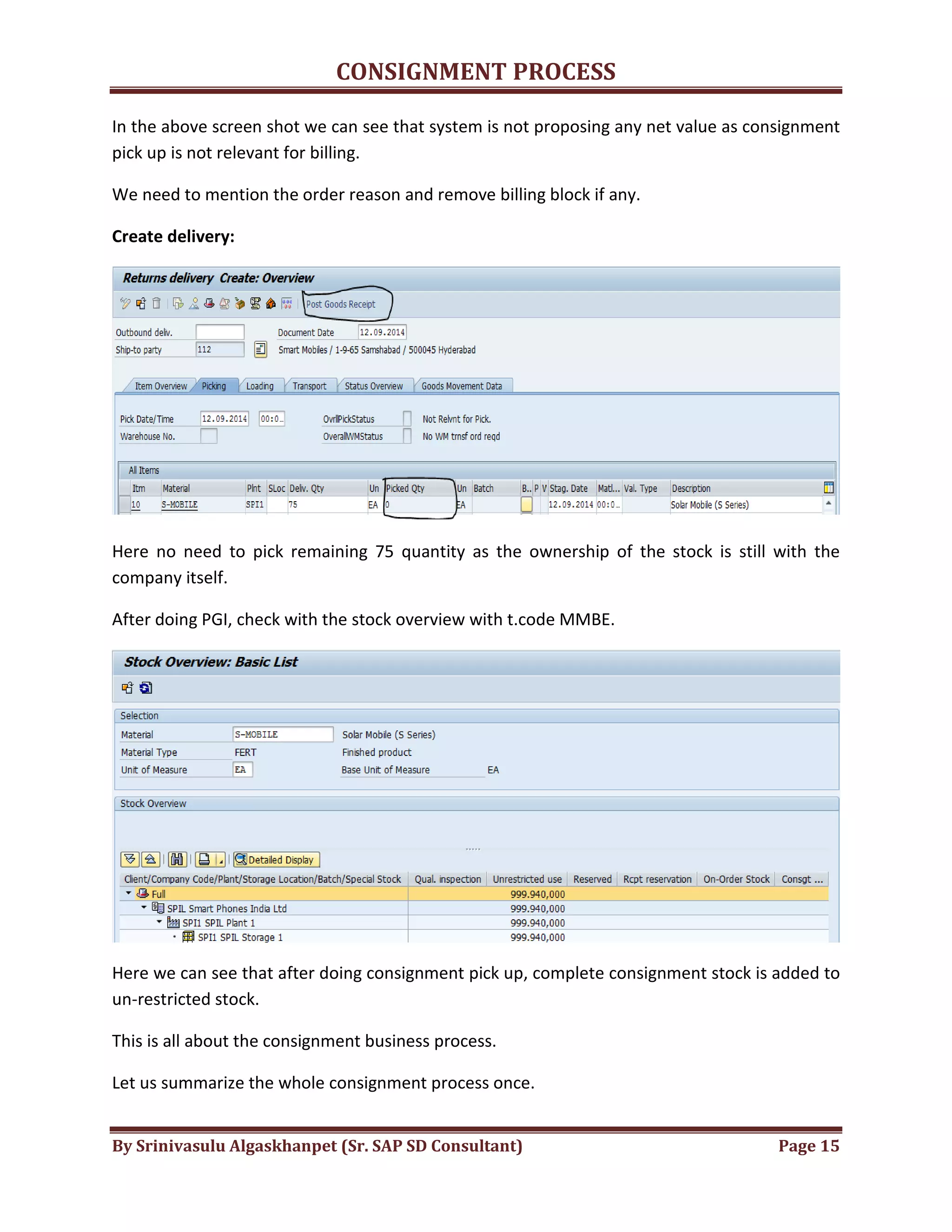

3. Each process uses a document type, item category, and movement type to reduce or add stock from unrestricted or consignment levels and generate accounting entries as needed. Billing only occurs for Issues.