Availability Check Configuration

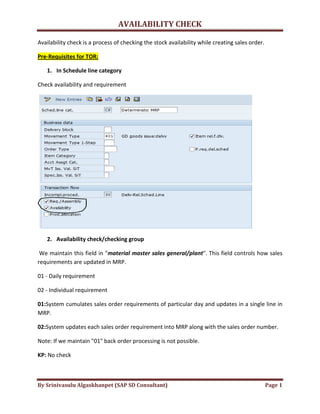

- 1. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 1 Availability check is a process of checking the stock availability while creating sales order. Pre-Requisites for TOR: 1. In Schedule line category Check availability and requirement 2. Availability check/checking group We maintain this field in "material master sales general/plant". This field controls how sales requirements are updated in MRP. 01 - Daily requirement 02 - Individual requirement 01:System cumulates sales order requirements of particular day and updates in a single line in MRP. 02:System updates each sales order requirement into MRP along with the sales order number. Note: If we maintain "01" back order processing is not possible. KP: No check

- 2. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 2 3. Requirement type should be determined into sales documentThe criteria to determine requirement type in sales document is: I. Strategy Group II. MRP Group III. Item category + MRP Type 4. In requirement class Check availability and requirement

- 3. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 3 Note: Requirement class will help to transfer the sales order requirements to MRP. Configuration for Availability Check: Availability Check can be configured in 3 ways. 1. Availability Check with ATP (Availability To Promise) 2. Availability Check with Product Allocation 3. Rule based Availability Check I. Availability Check with ATP (Availability To Promise) Path: SPRO > S&D > Basic Functions > Availability Check & Transfer of requirement > Availability Check > Availability check with ATP > Define Checking group "Checking Group" is nothing but availability check field in "material master sales general/plant"

- 4. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 4 In this configuration step we can define our own checking group. The standard checking groups are: 01 – Daily Requirements 02 – Individual Requirement KP - No Check This configuration step will also help to control how the sales requirement should be transferred to MRP. Note:Availability check is material and plant specific II. Define Material Block for other Users: Path: SPRO > S&D > Basic Functions > Availability Check and Transfer of requirements > Availability Check > Availability Check with ATP > Define material block for other users If multiple users are accessing availability check for the same material in the same plant then system performs availability check for the first user and block availability for the other users. In this step with the combination of availability check and initiator we check block. Initiator: A - Sales Order C - Reservations B - Delivery III. Define checking groups default values: Path: SPRO > S&D > Basic Functions > Availability Check and Transfer of requirements > Availability Check > Availability Check with ATP > Define checking groups default values

- 5. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 5 If we maintain checking group here it automatically proposes by default while creating material master. In this configuration step we maintain checking group to the combination of material type and plant. IV. Carry out Control for Availability Check: We also call it as "scope of check". We configure scope of check with the combination of "Checking group and Checking rule".

- 6. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 6 "Checking Rule" specifies in which transaction we want to configure availability check. A - Sales Order B - Delivery 1. Include Safety stock:This is the minimum stock level which company has to maintain to meet the future emergency requirements. We have this field in "Material master MRP 2" view. If we check this field system will consider safety stock also while performing availability check. 2. Stock in Transit:We use this field in STO Process In STO two-step process where we do delivery in supplying plant the stock will be displayed as stock in transit in receiving point. If we check this system will consider the stock which is in transit also, while performing availability check in receiving point. 3. Include Quality Inspection Stock:If we check this system will consider the stock which is in quality inspection while performing availability check. The movement type for quality inspection is "503" Note:To check the result "post the un-restricted stock" by using movement type "503" Stock Posting - MB1C Stock Overview - MMBE Check and uncheck the field and check the result. 4. Include Blocked Stock:If we check this field system will consider the stock which is blocked while performing availability check. The movement type for blocked store is "505" Note:Post the blocked stock and check in stock overview. Check and uncheck this field and see the result by creating order. 5. Check without RLT:If we check this field system will not confirm the quantities if the stock is not available. If we uncheck this, system will confirm the quantities in future dates based on RLT.

- 7. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 7 6. Include Purchase Orders:If we check this system will consider the inward movements (the purchase order stock) while performing availability check. 7. Include Purchase Requisition:In real time we don't depend on purchase requisition. Because, it is not the exact source for getting the stock. 8. Include Sales Requirement:If we check this system will deduct the open order quantities from stock while performing availability check. If we uncheck this system will consider the stock while performing availability check. Note:Create material, post the stock and check the result. Schedule line > Environment > Availability 9. Include Deliveries:Whenever we create deliveries the deliveries will also updates in "MD04". If we check this system deducts open delivery quantities from stock while performing availability check. If we uncheck this system will not deduct open delivery quantities from stock while performing availability check. V. Define Procedure by Requirement Class: In this configuration step we need to check requirement and availability. VI. Define Procedure by schedule line category: In the configuration step we check availability and requirement fields. VII. Determine Procedure for each delivery item category: This configuration controls whether to perform availability check in delivery document or not. In below scenarios we perform availability check in delivery document. a. Delivery without reference b. Adding new line items in deliveries c. Increase or decrease the quantities in deliveries d. Stock Transfer

- 8. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 8 Exercise: 1. Create Order without posting stock and check how it is proposing the stock? System is not confirming any quantity as there is no stock 2. Post stock with quantity 5 and created order with 5 quantity and check Order quantity is 5 and system also confirmed quantity of 5.

- 9. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 9 3. Now create order with quantity 10 and check. When we enter order quantity and press enter system will check the availability. As we have stock of 5 quantity system is proposing only 5 quantities. Click on tick mark and check the schedule lines. Even the order quantity is 10 system confirms only 5.

- 10. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 10 4. Maintain RLT (2 days) in Material master and uncheck the field check without RLT in scope of check and create order. In this scenario we can see that system is confirming the 5 quantity and proposing the delivery date for another 5 quantity in future as we maintained RLT. Click on the tick mark and check the schedule lines. System confirming the quantities on 2 different dates. This is all about the availability check. We can do same this by posting quality inspection stock, block stock, stock in transit etc.

- 11. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 11 Back Order Processing: Whenever high delivery priority customer places an order, if the stock is not available then we go back to open orders of low delivery priority customers and cancel the confirmations and assign to high delivery priority customer order. Note: The back order processing is available only for those materials that have the individual requirements i.e., in material master record the parameter for "availability check" must be "02". The T. Code to create checking rule is “OPJL” The T. Code to assign checking rule to availability check is “OVZ9” After maintaining these setting continue with the configuration for back order processing. Configuration for Back Order Processing: 1. Checking Rule for updating backorders: Path: SPRO > S&D > Basic functions > Availability check and transfer of requirements > Availability check with ATP > Checking rule for updating back orders Here we assign checking rule "BO" to our plant If we don’t find our plant in this path, in this case we need to maintain plant parameters. Path: SPRO > Production > Material Requirements Planning > Plant Parameters > Carry out overall maintenance of plant parameters > Create 2. Carryout control for availability check: Here maintain the combination for checking group "02" and checking rule "BO"

- 12. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 12 Note: a. If the plant is not displayed in backorder then maintain plant parameter for that plant. Path: SPRO > MM > Inventory management & Physical inventory > Plant Parameter Select the standard Plant 1000 and click on copy and maintain plant parameter b. Maintain plant parameter in production Path: SPRO > Production > Material requirement planning > Plant parameter > Carryout overall maintenance of plant parameters Click on copy "1000" in from plant "SPI1" in to plant and again click on copy.

- 13. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 13 3. Define Default Settings: Fixed date and quantity: If we check this system will not allow users to change delivery dates and confirmed quantities. Availability checking rule:In case of shortages system proposes dialogue box with the help of availability check rule. Scenario for Back Order Processing: i. Create a Material: P-Mobile MRP Type: PD Availability check: 02 Strategy group: 10 ii. Create 2 Customer: 112 – Low delivery priority customer 130 – High delivery priority customer iii. Do stock posting for created material T.Code: MB1C Qty: 5 iv. Create order for low delivery priority customer (Qty:2) and check in schedule line data

- 14. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 14 v. Create another order for low delivery priority customer (Qty: 3) and check the confirmed quantity in schedule line data. vi. Create another order for high delivery priority customer (Qty: 3) and check the confirmed quantity in schedule line data.

- 15. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 15 System will not confirm any quantity as there is no stock. So in order to confirm the quantity to high delivery priority customer do the back order processing. T.Code: v_ra Enter material, plant and execute. Select the orders from which we want to cancel the confirmations and select the order to which you want to assign the confirmed quantity

- 16. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 16 Select both and click on Backorders. Select the Confirmed order and click on change confirmation.

- 17. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 17 Remove committed quantity and click on okay We can see that the confirmed quantity becomes “0”. After that click on high delivery priority customer order and click on change confirmation.

- 18. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 18 Enter the committed quantity and click on okay . And save the document. Go to the order of high delivery priority customer and check the committed quantity in schedule lines. System confirms the quantity.

- 19. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 19 Re-scheduling: If system performs backorder processing automatically then we call it as re-scheduling. i. Create Material and post the stock of 5 quantities. In our case it is Q-Mobile. ii. Create order for low delivery priority customer and save. (Qty: 5) And check in schedule line to see how much quantity got confirmed. iii. Create order of high delivery priority customer and check schedule line. (Qty: 5)

- 20. AVAILABILITY CHECK By Srinivasulu Algaskhanpet (SAP SD Consultant) Page 20 iv. T.Code for Re-scheduling is V_V2 Here we can see the for high delivery priority customer quantity has been confirmed automatically. And also check the same in schedule lines for high delivery priority customers order. This is all about availability check, back order processing and re-scheduling process.