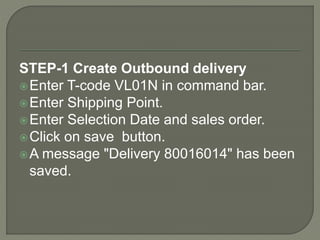

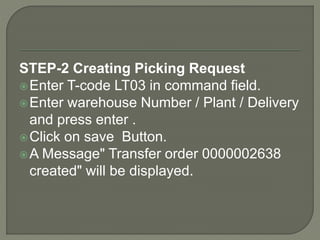

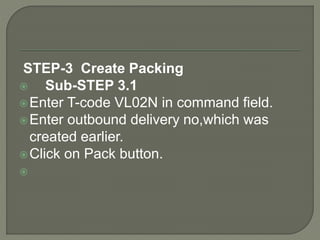

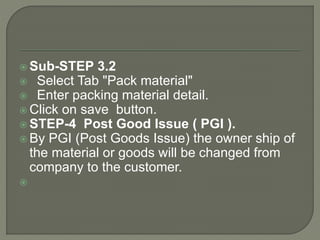

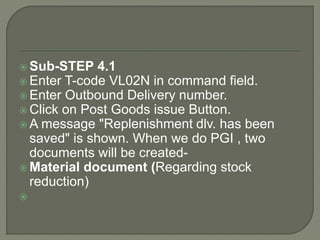

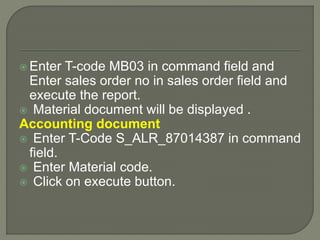

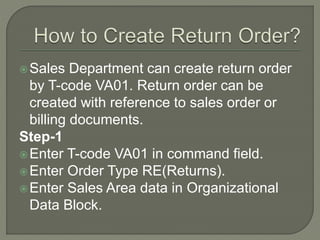

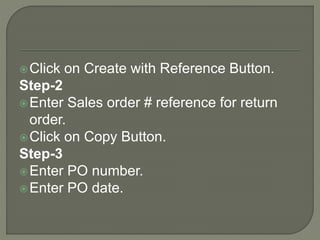

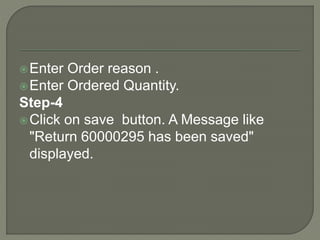

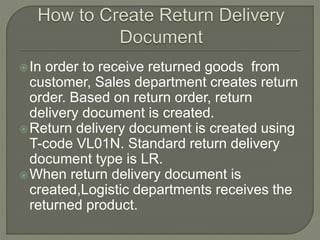

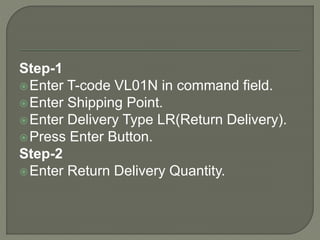

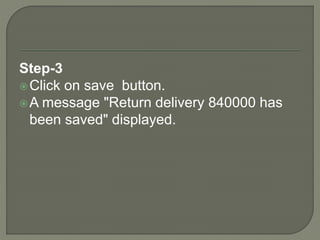

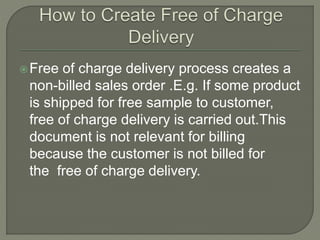

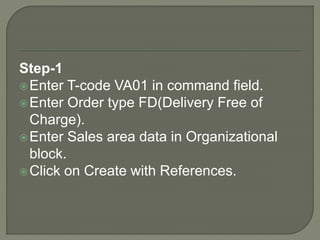

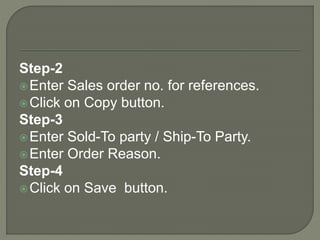

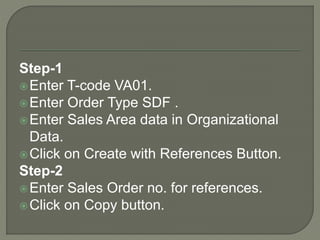

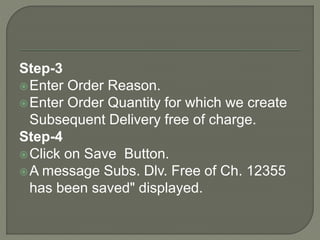

The document discusses key concepts in SAP SD (Sales and Distribution) module including shipping point determination, picking, packing, post goods issue, returns processing, free of charge deliveries, and subsequent deliveries. It provides step-by-step instructions for configuration and processes. Shipping point, loading group, and plant determine where goods will be delivered from. Picking prepares items for shipping using transfer orders. Packing can be done manually or automatically. Post goods issue transfers ownership to the customer. Returns and free or subsequent deliveries are handled through specific order types and documents.