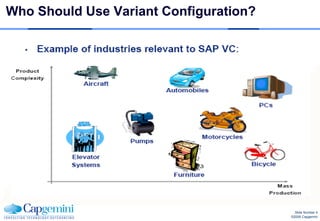

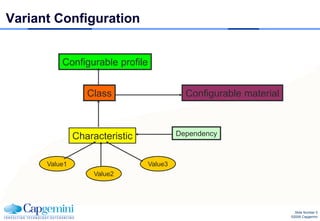

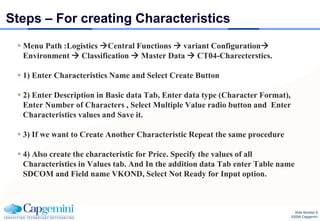

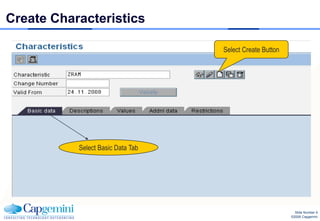

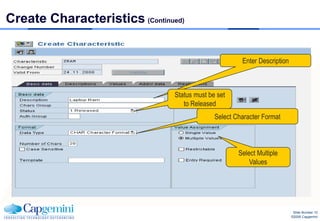

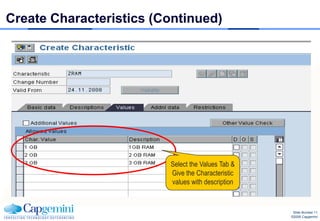

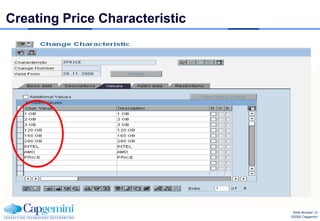

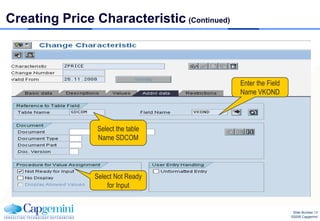

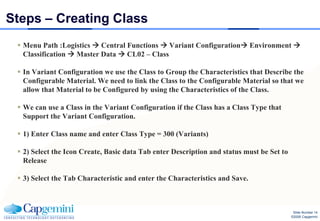

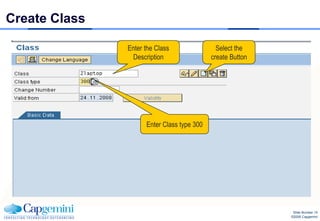

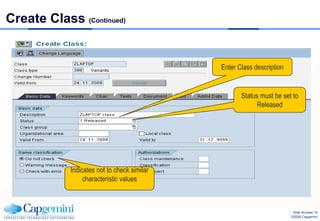

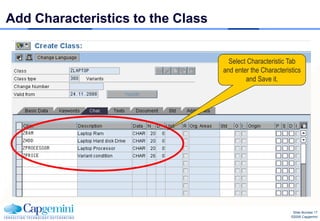

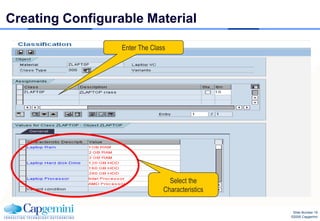

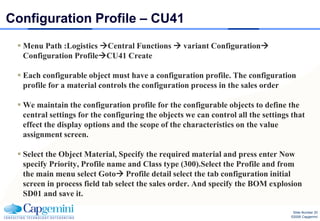

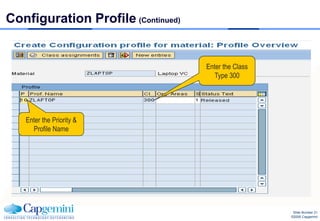

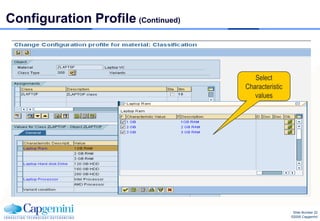

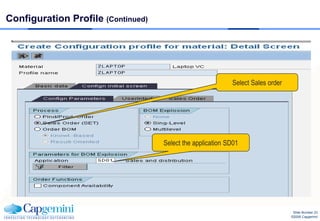

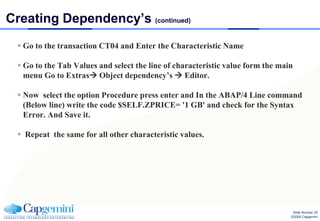

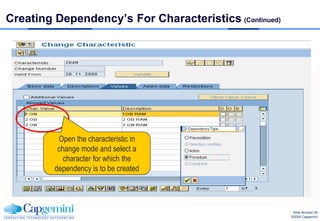

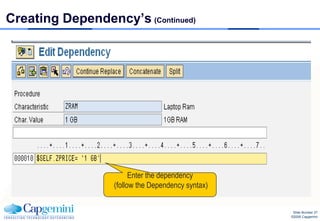

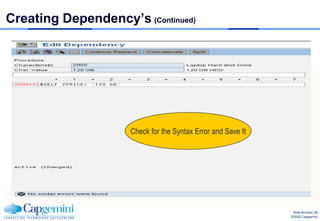

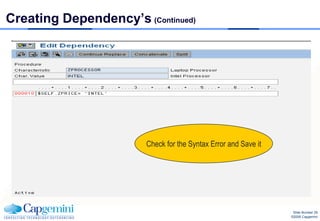

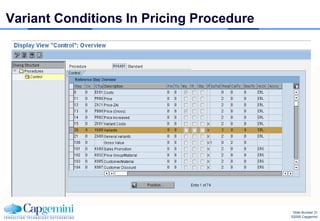

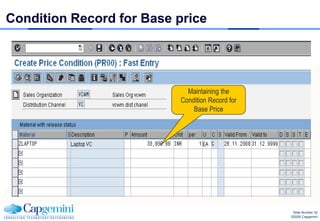

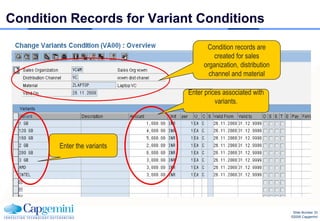

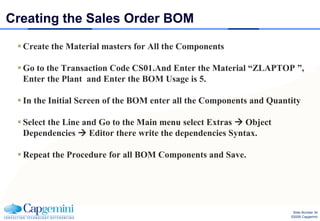

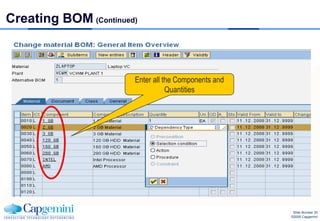

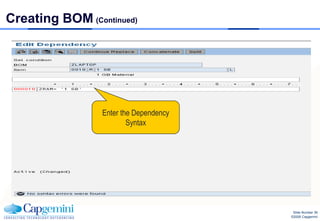

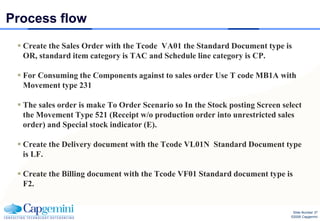

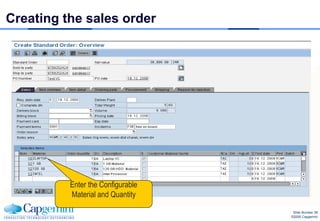

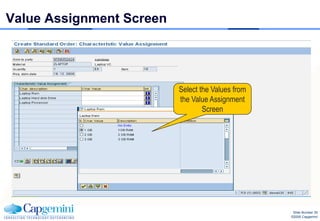

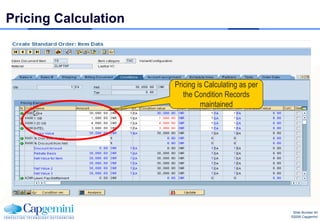

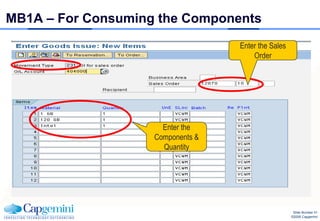

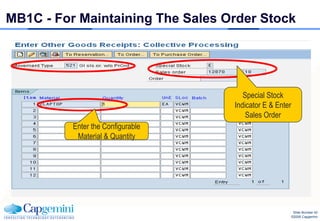

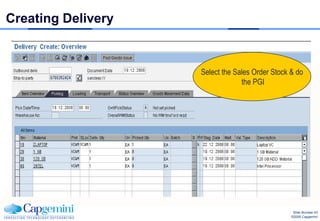

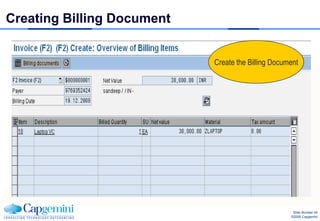

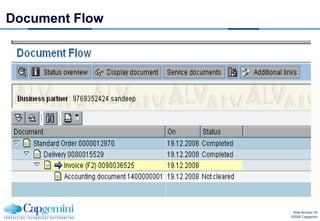

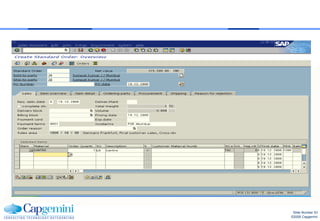

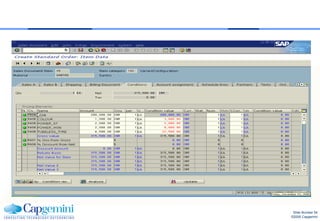

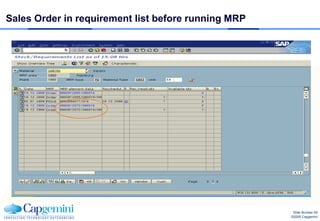

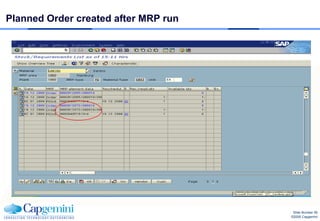

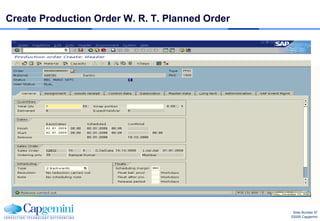

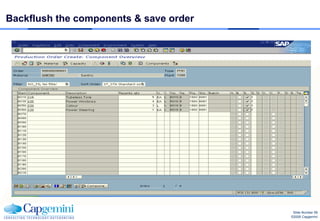

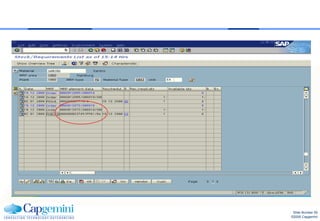

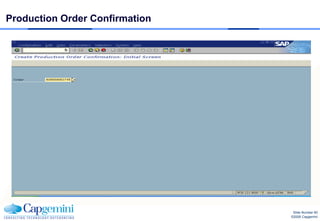

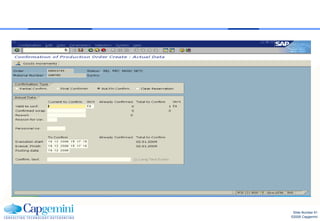

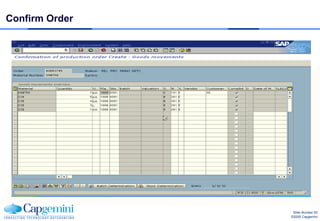

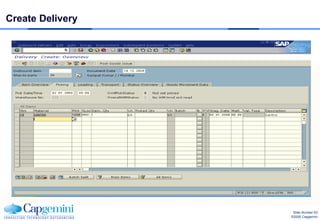

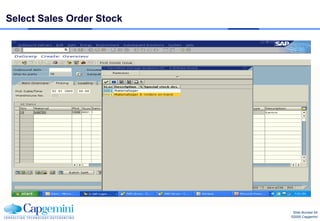

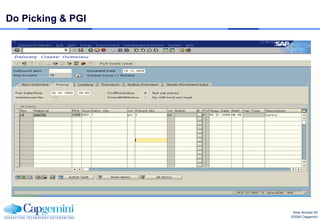

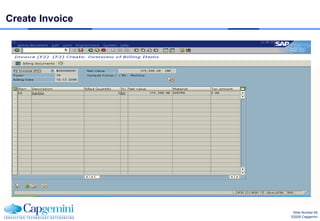

The document outlines the purpose and functions of variant configuration in manufacturing, allowing customization of products based on customer requirements without creating separate materials for each variant. It details the steps for creating characteristics, classes, and configuration profiles, as well as managing dependencies and pricing conditions. Additionally, it explains the process flow for sales orders, including BOM creation, component consumption, and invoicing.