The document outlines the ATP (Availability to Promise) procedure in the SAP Sales and Distribution (SD) process, detailing prerequisites, scope, and actions for managing sales orders. It covers scenarios involving both stock availability and stock absence, explaining the role of material master data and system checks in confirming delivery dates. The document emphasizes the importance of coordinated planning between production and sales to ensure accurate ATP results for sales orders.

![Page [2]

Agenda

What’s ATP (Availability to Promise)

Prerequisites

Scope of ATP

Actions ATP in Sales Document

Sales Order with ATP process flow

Scenario 1 : Sales Order without Stock

Scenario 2 : Sales Order with Stock & Supply](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-2-320.jpg)

![What’s ATP

(Availability to Promise)

When you enter a sales order, you can confirm the delivery of the goods for the

required delivery date.

Page [3]](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-3-320.jpg)

![Prerequisites

Material Master Data

Sales / Plant View

Availability check filed : 02

MRP 1 View

MRP type field : MX or PD

MRP group : M070

Page [4]](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-4-320.jpg)

![Prerequisites

Material Master Data

MRP 1 View

MRP type field : M0

MRP group : M070

Page [6]](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-6-320.jpg)

![Page [7]

Scope of ATP

Checking group : 02

Checking rule : A

Elements : Stock

UC stock

Safety Stock

Quality Inspection

Stock in transfer

Elements : inward/outward movement of goods

Sales requirements

Delivery requirements

Production Orders

Reservations

Dependent requirements](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-7-320.jpg)

![Page [ 8]

Sales Order Creating

Req. deliv. date in order header

Material and Order quantity

Sales Order Modification

Item’s Order quantity changed

Item’s delivery date changed

After new delivery schedule

Change to fixed qty and date

Change of Plant/Storage location

Inititating a check manually

Performing a check manually in Sales document

Actions ATP in Sales Document](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-8-320.jpg)

![Page

[11]

Sales Order with ATP process flow

SORO010 Sales order process

• Sales order

• Item no

• Delivery date

• Quantity

• ATP confirmed quantity

Production & Sales

Coordination

• Available Date for Planning

• Sales order

• Production

• Procurement

• Stock

PPPD010 Create Production

Order Process

• Production Order

• GR Date

• Order Quantity

PPMP020 MPS/MRP Process

• Stock

• Sales Order

• Production Order

• …ETC

Sales person Checks MRP(ATP)

Result

• Sales order

• Delivery date

• Available Quantity

Sales Person confirmed the

delivery date with customer](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-11-320.jpg)

![Page

[12]

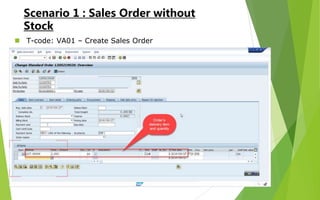

Scenario 1 : Sales Order without

Stock

Stock : 0 EA (UC)

Sales order

Supply : Production order : 1 EA

Order no Item no Req. date Req. Quantity(EA)

1200219026 10 2016/9/27 2

ATP results

Order no Item no Rec./Req.

date

Rec/Req.

Quantity(EA)

ATP Quantity Available

Quantity

20810000025 2016/9/26 1 1 1

1200219026 10 2016/9/27 2 1 -1

Production Order GR. date GR. Quantity(EA)

20810000025 2016/9/26 1](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-12-320.jpg)

![Page

[15]

Scenario 1 : Sales Order without

Stock

T-code: VA01 - Sales order ATP information](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-15-320.jpg)

![Page

[16]

Scenario 1 : Sales Order without

Stock

T-code: MD4C

Sales order information

Stock and requirements list](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-16-320.jpg)

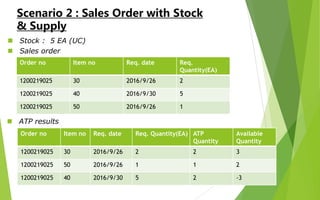

![Page

[18]

Scenario 2 : Sales Order with Stock

& Supply

T-code: VA01 – Create Sales Order](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-18-320.jpg)

![Page

[19]

Scenario 2 : Sales Order with Stock

& Supply

T-code: VA01 – ATP Control delivery proposals](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-19-320.jpg)

![Page

[20]

Scenario 2 : Sales Order with Stock

& Supply

T-code: VA01 – Sales order ATP information](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-20-320.jpg)

![Page

[21]

Scenario 2 : Sales Order with Stock

& Supply

T-code: MD4C

Sales order information

Stock and requirements list](https://image.slidesharecdn.com/sapatpinsalesdoc-161115062317/85/SAP-ATP-check-for-Sales-Order-21-320.jpg)