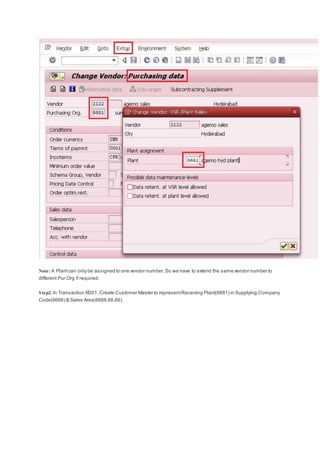

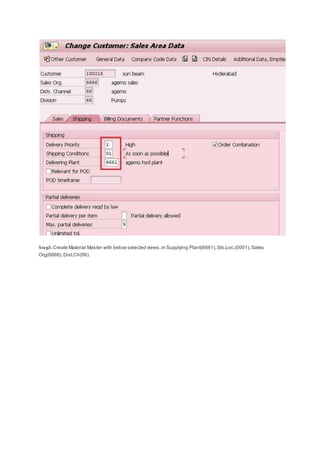

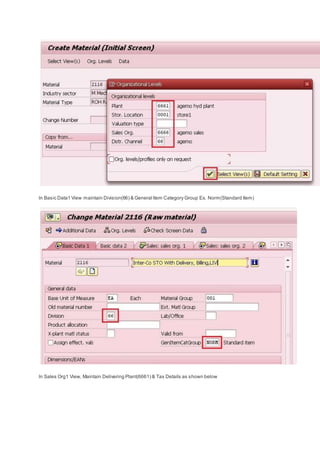

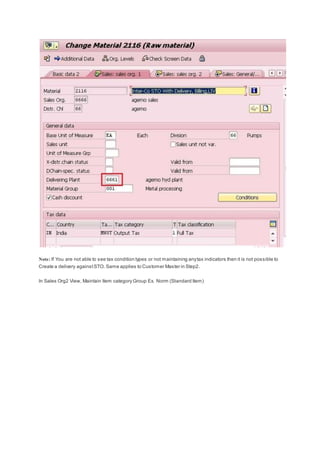

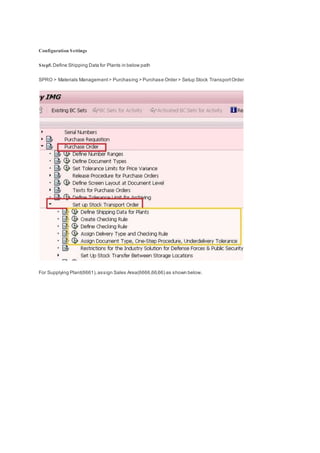

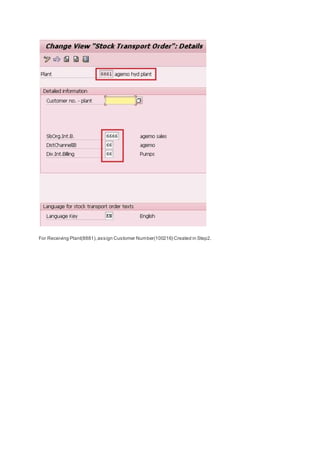

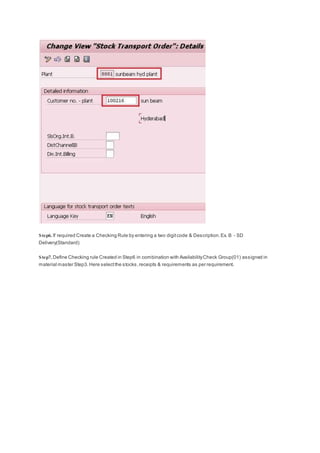

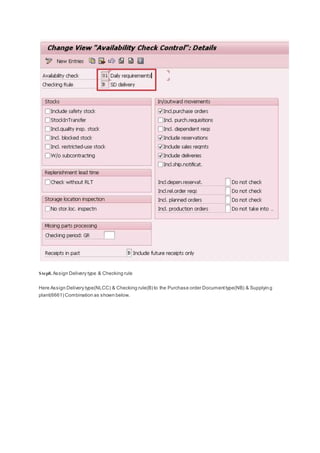

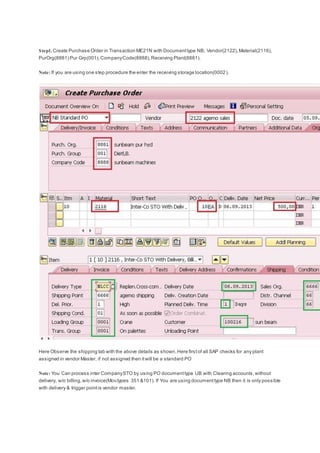

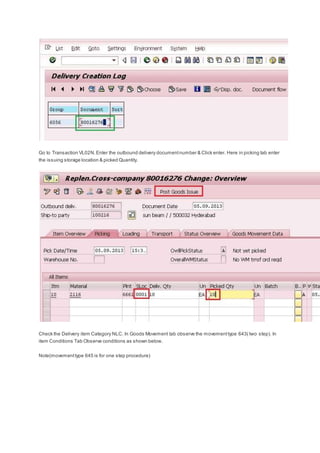

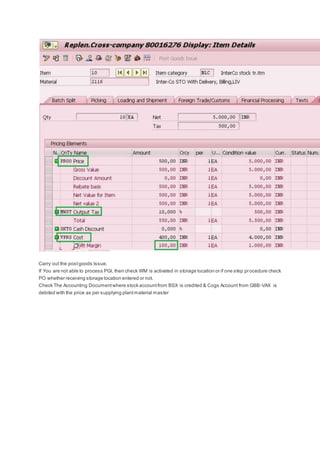

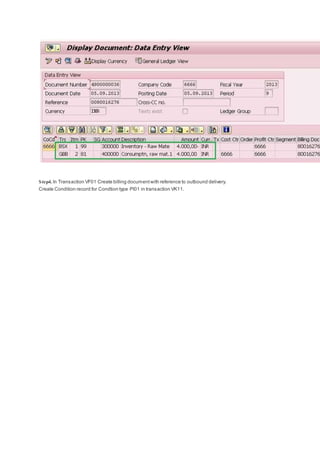

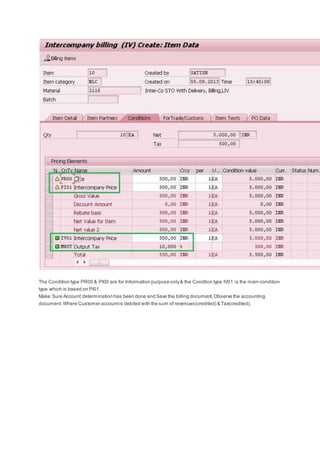

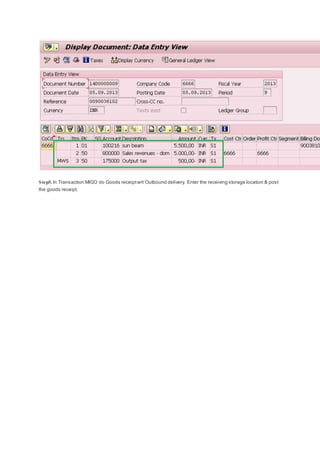

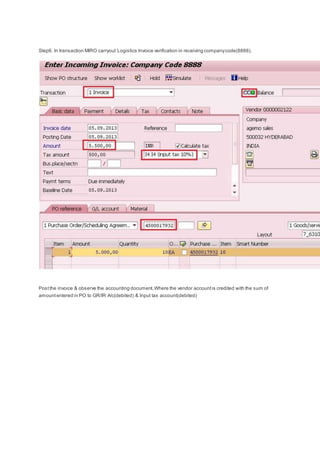

This document explains how to set up an inter-company stock transport order with SD delivery, billing, and logistics invoice verification between two companies. It involves 10 steps to configure the required master data, including vendor, customer, material, tax, and shipping point determination. It also provides testing steps to generate a purchase order, outbound delivery, goods movement, billing document, goods receipt, and logistics invoice verification to complete the inter-company process. Common error messages are listed at the end to troubleshoot any issues.