This document summarizes an export planning and dispatch system implemented at GHCL Limited to streamline their export process. The key points are:

1. The system was designed to simplify the export process, make it more user-friendly, integrate data to reduce duplicate entry, automate documentation, and reduce IT costs like SAP licensing.

2. It improved upon the standard SAP process by reducing the number of stages from 8 to 12 screens, requiring less skilled users and reducing SAP licensing costs.

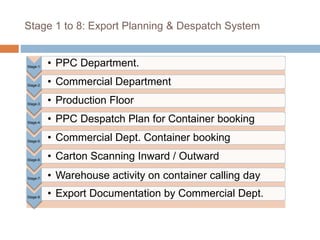

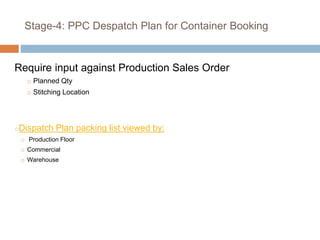

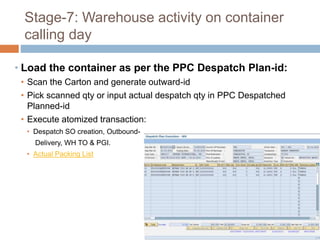

3. The 8 stages include planning by the PPC department, commercial involvement, production updates, dispatch planning, container booking, carton scanning, warehouse activities and export documentation.