This document provides an overview of Hazard and Operability Studies (HAZOP). It defines HAZOP as a formal procedure to identify hazards in chemical processes. The summary includes:

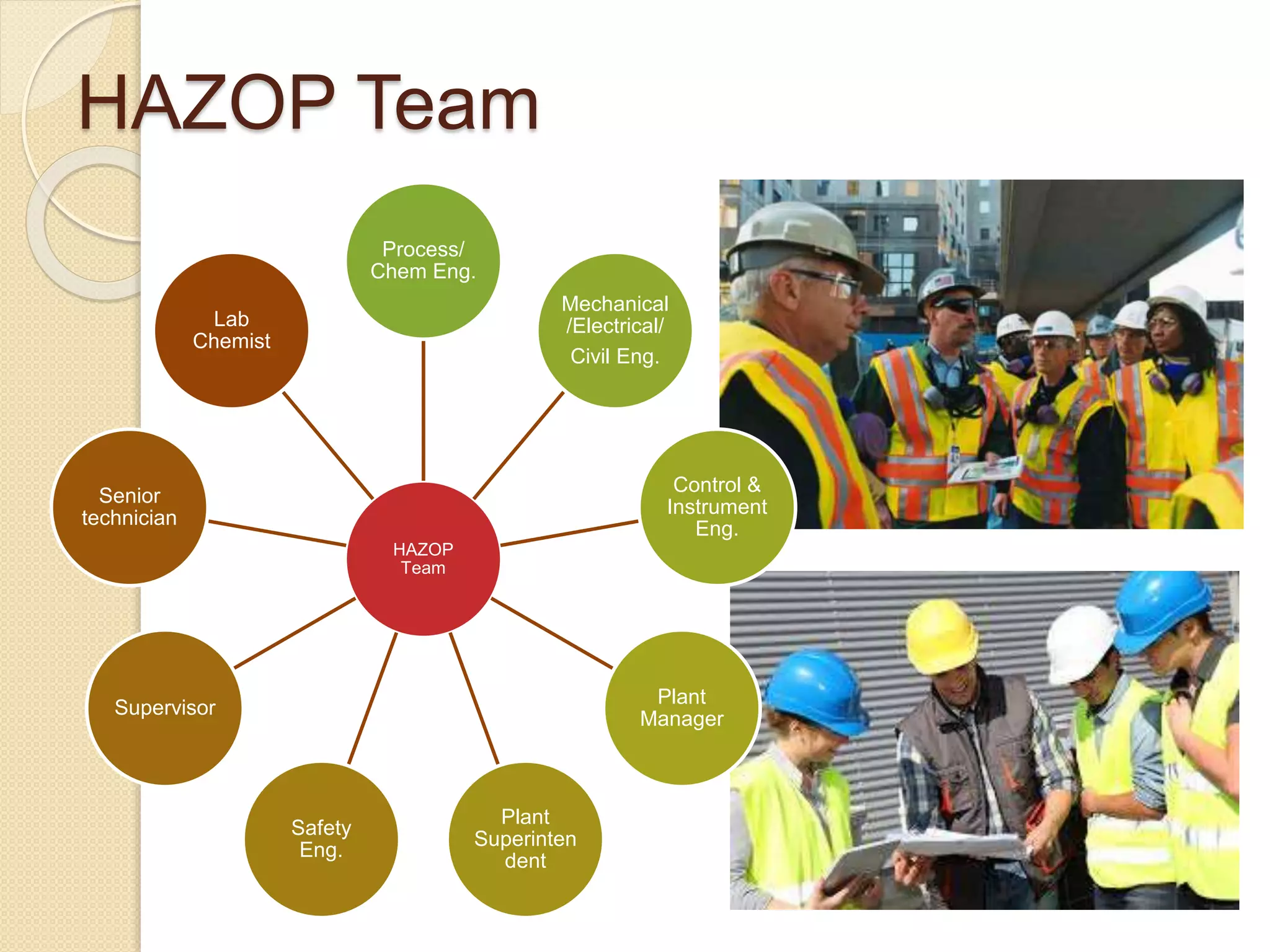

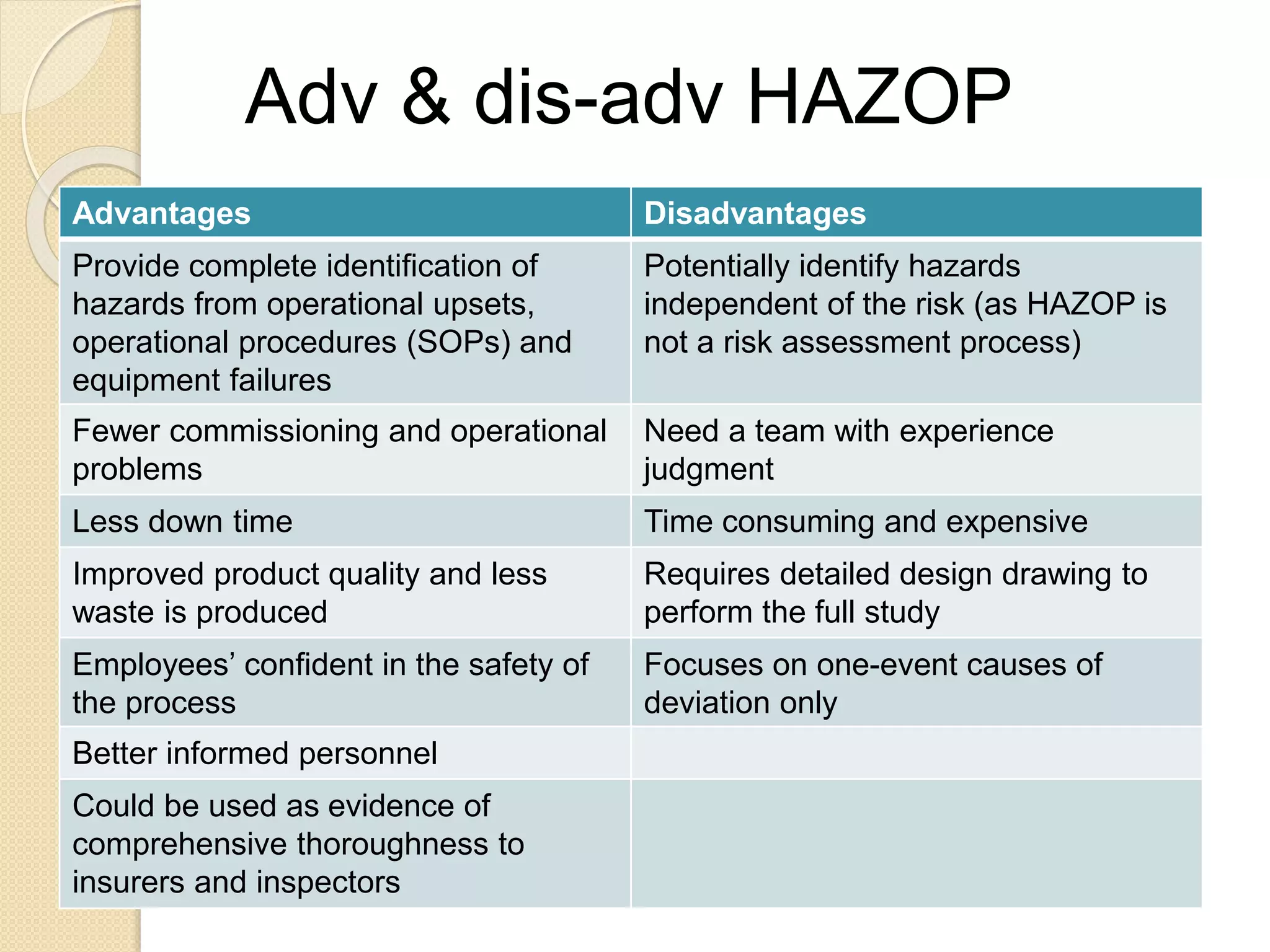

- HAZOP identifies potential hazards, failures, and operability problems through a team approach including designers, operators, and safety experts.

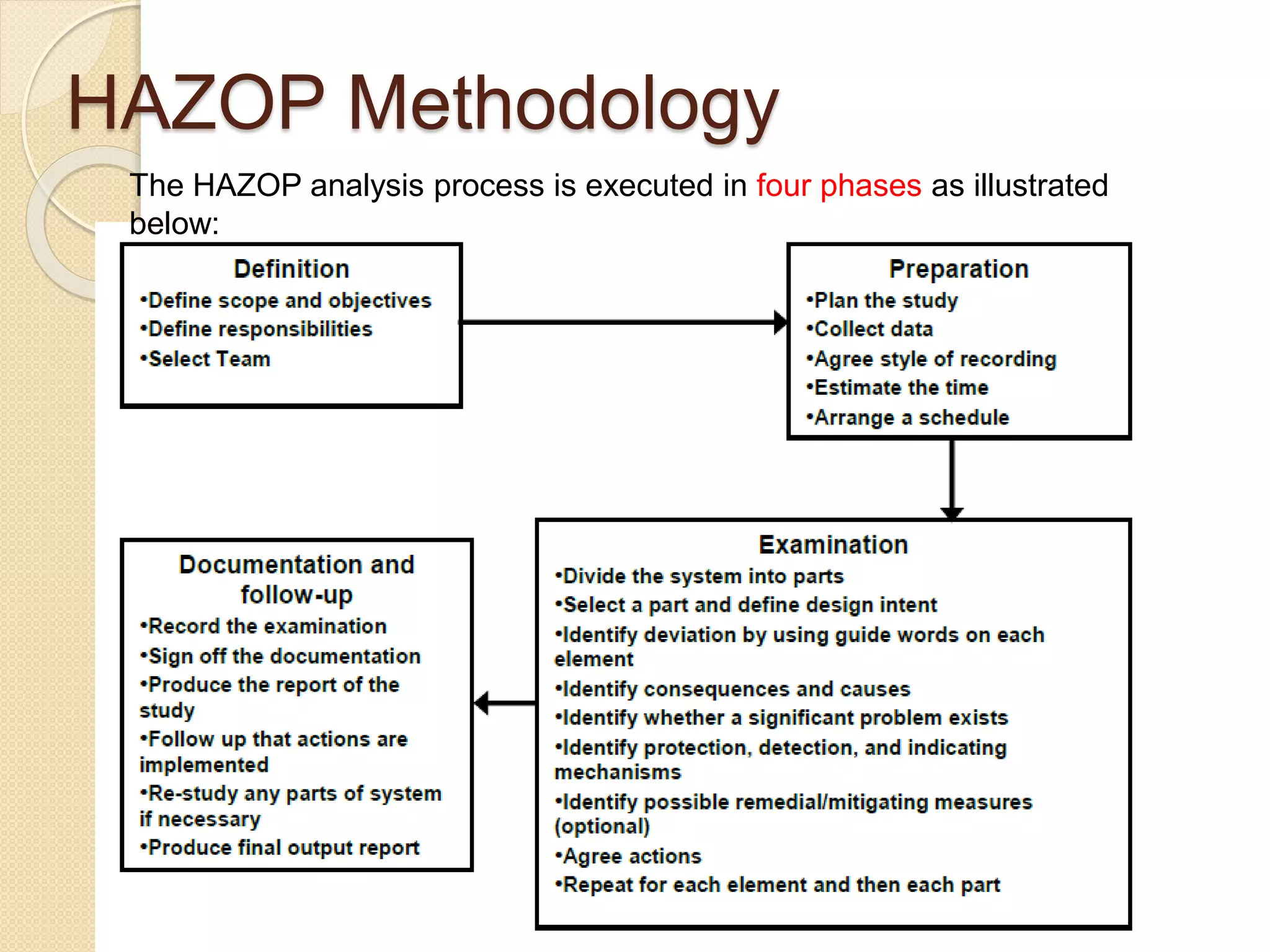

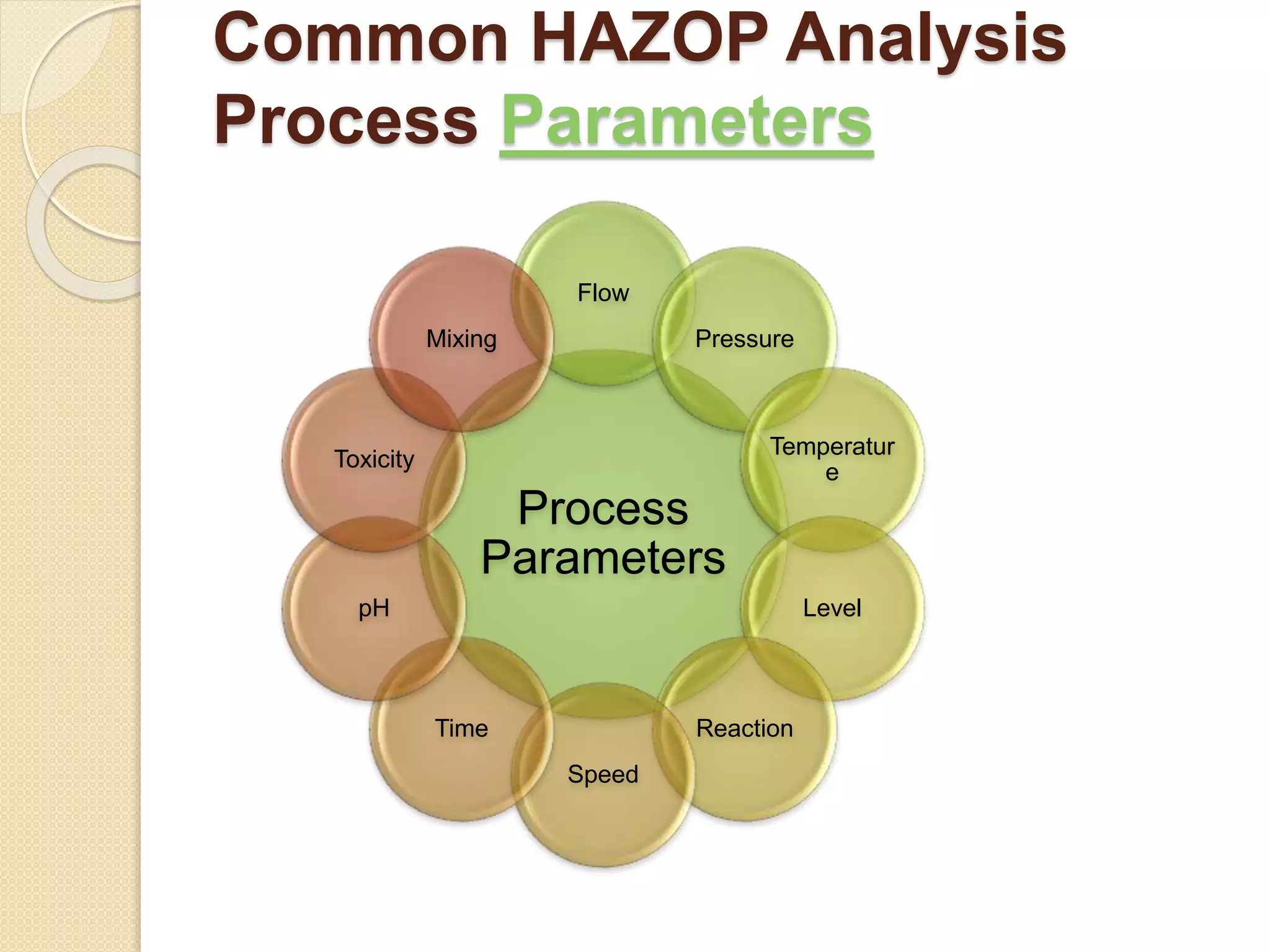

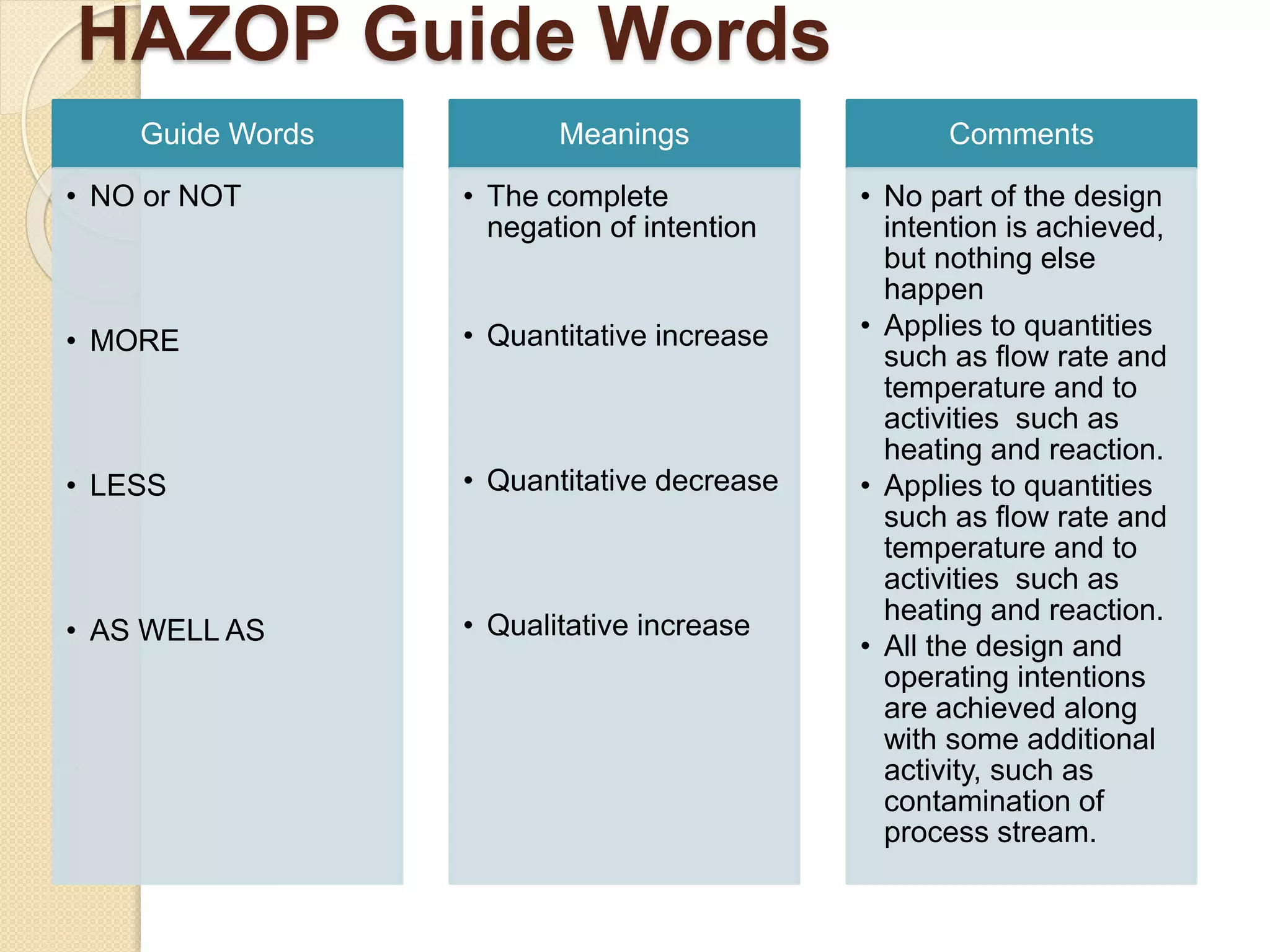

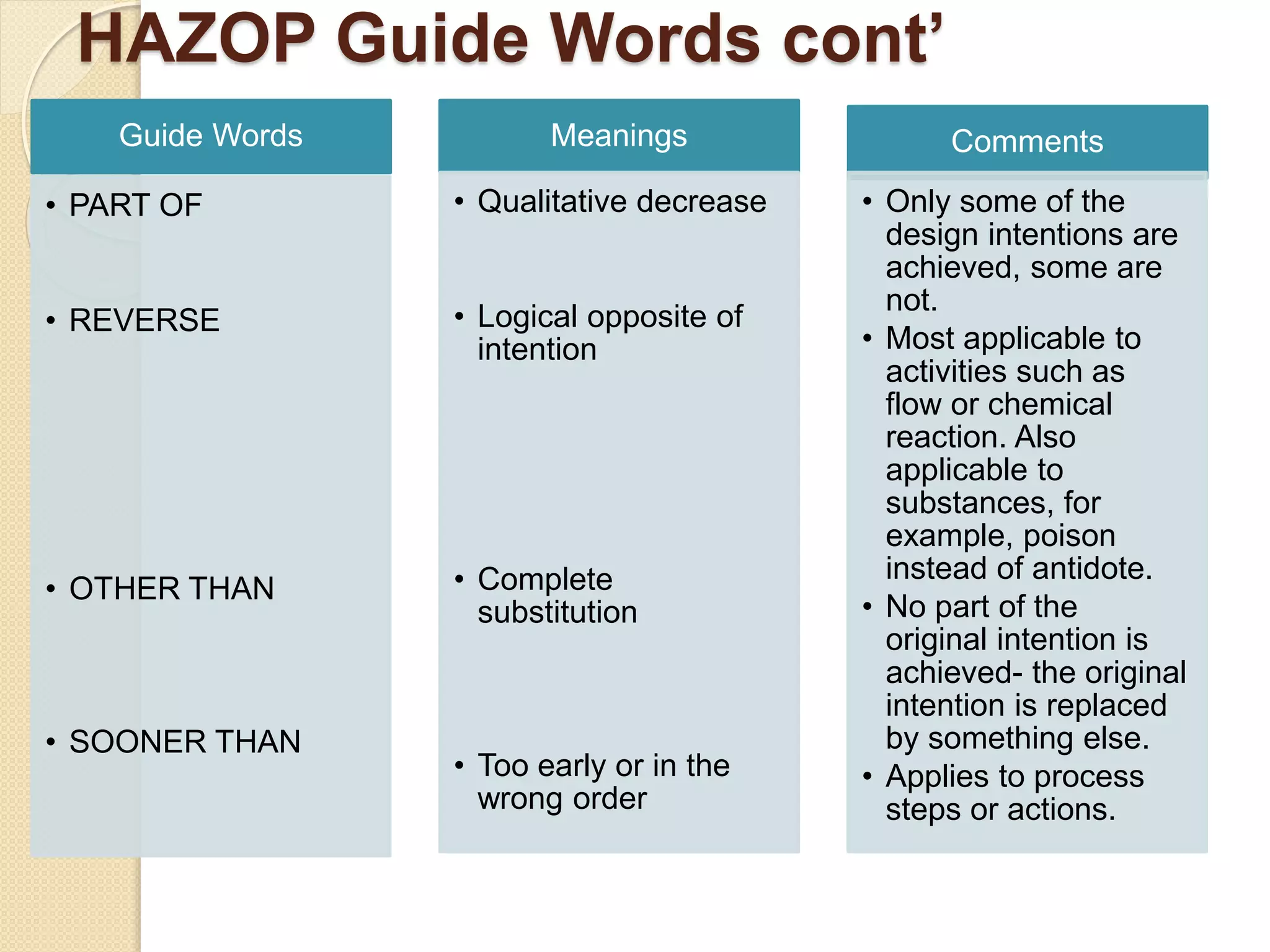

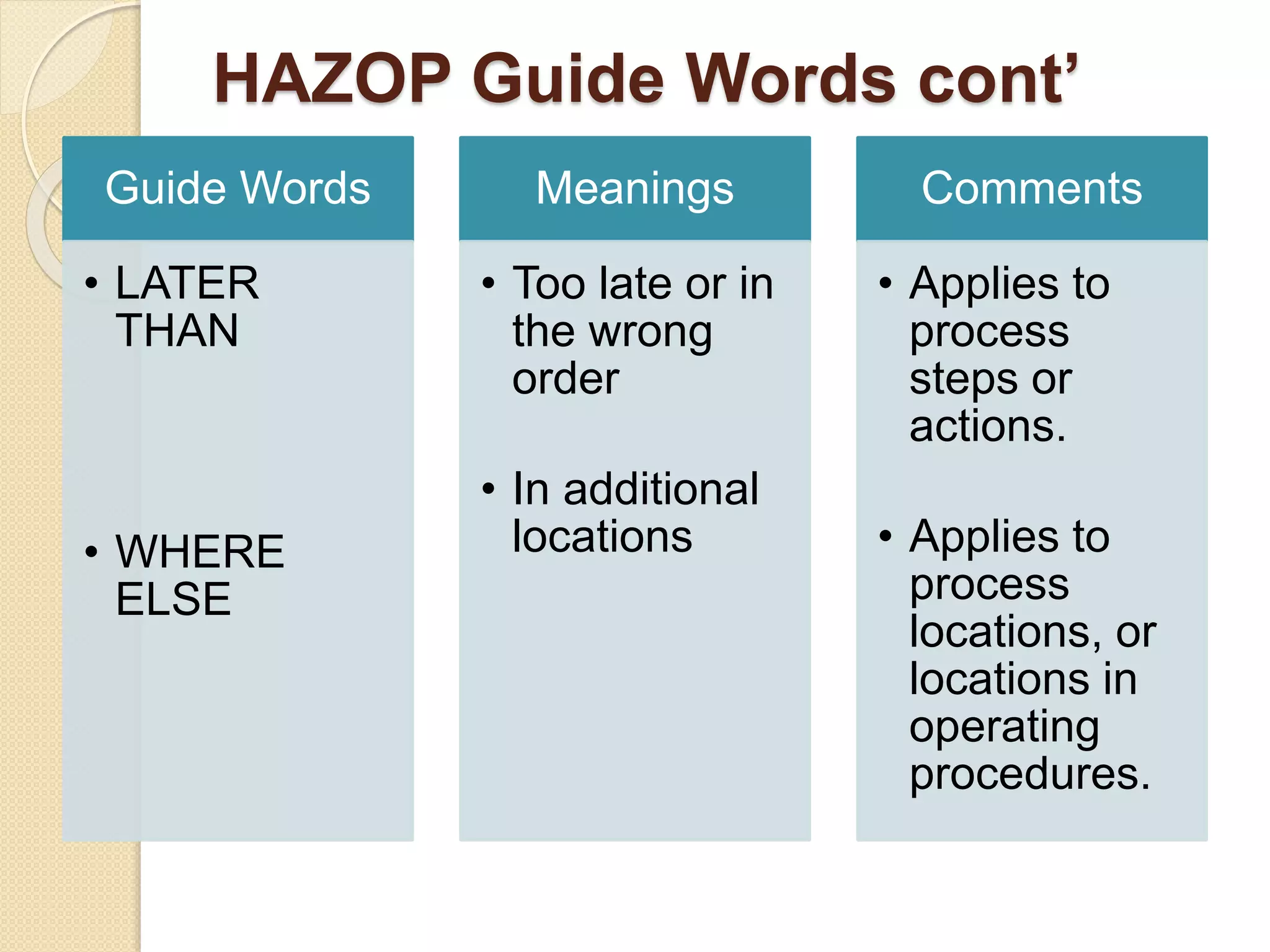

- The HAZOP process involves dividing the system into nodes, applying guide words like "no," "more," and "part of" to process parameters to suggest deviations, and evaluating causes and consequences to recommend actions.

- Benefits of HAZOP include fewer problems during commissioning and operation, improved safety and product quality, and evidence of due diligence for insurers.