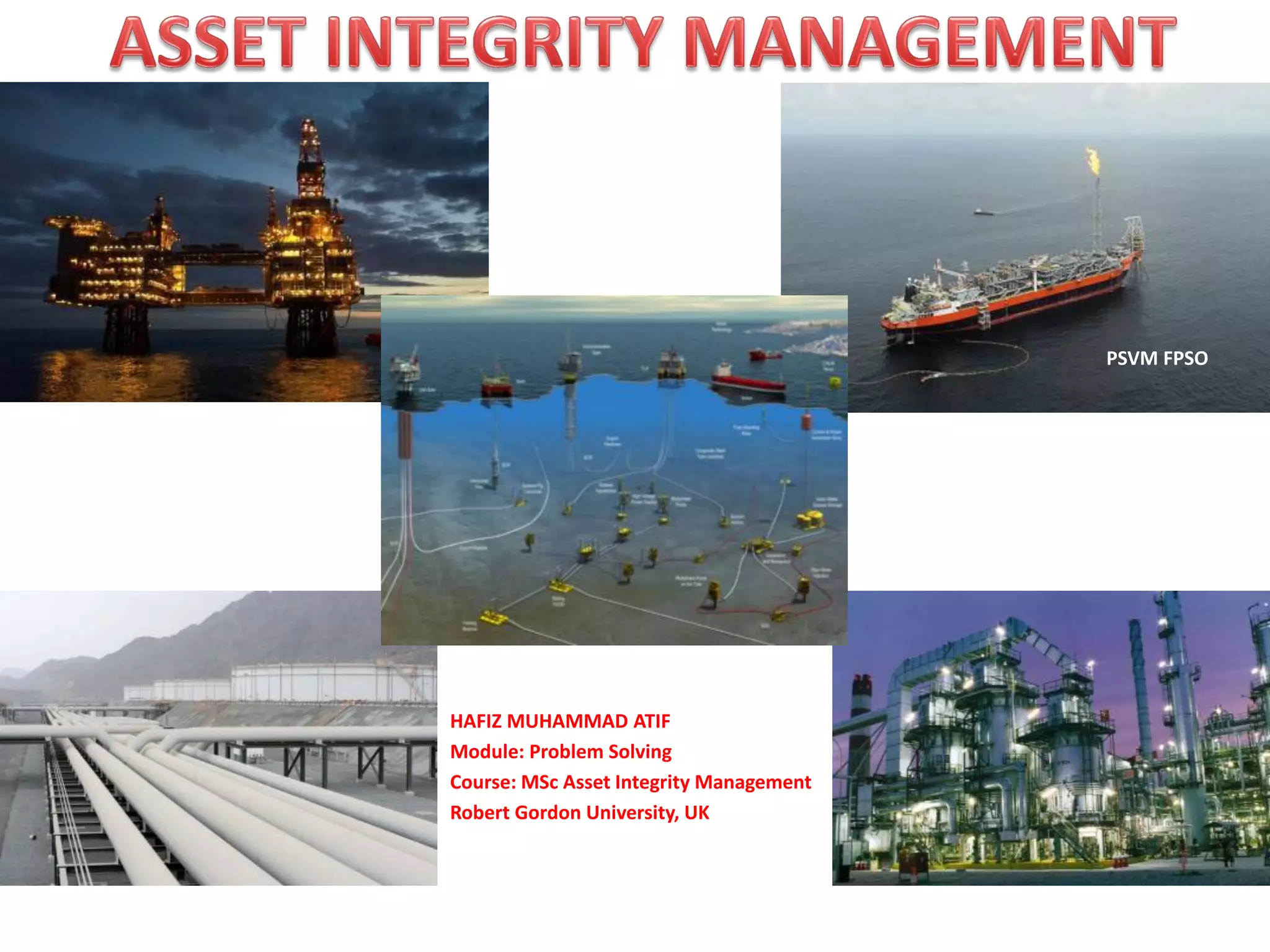

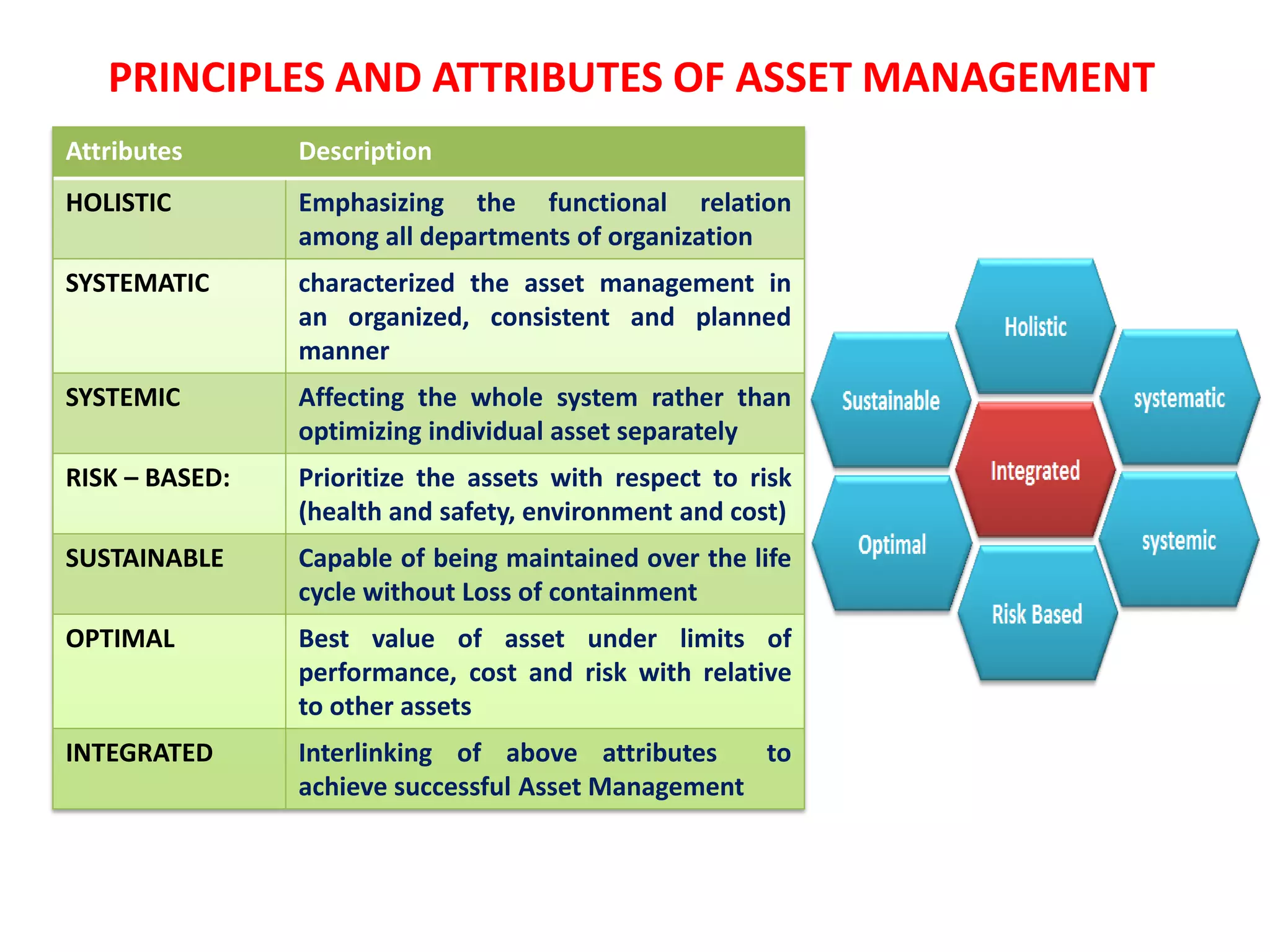

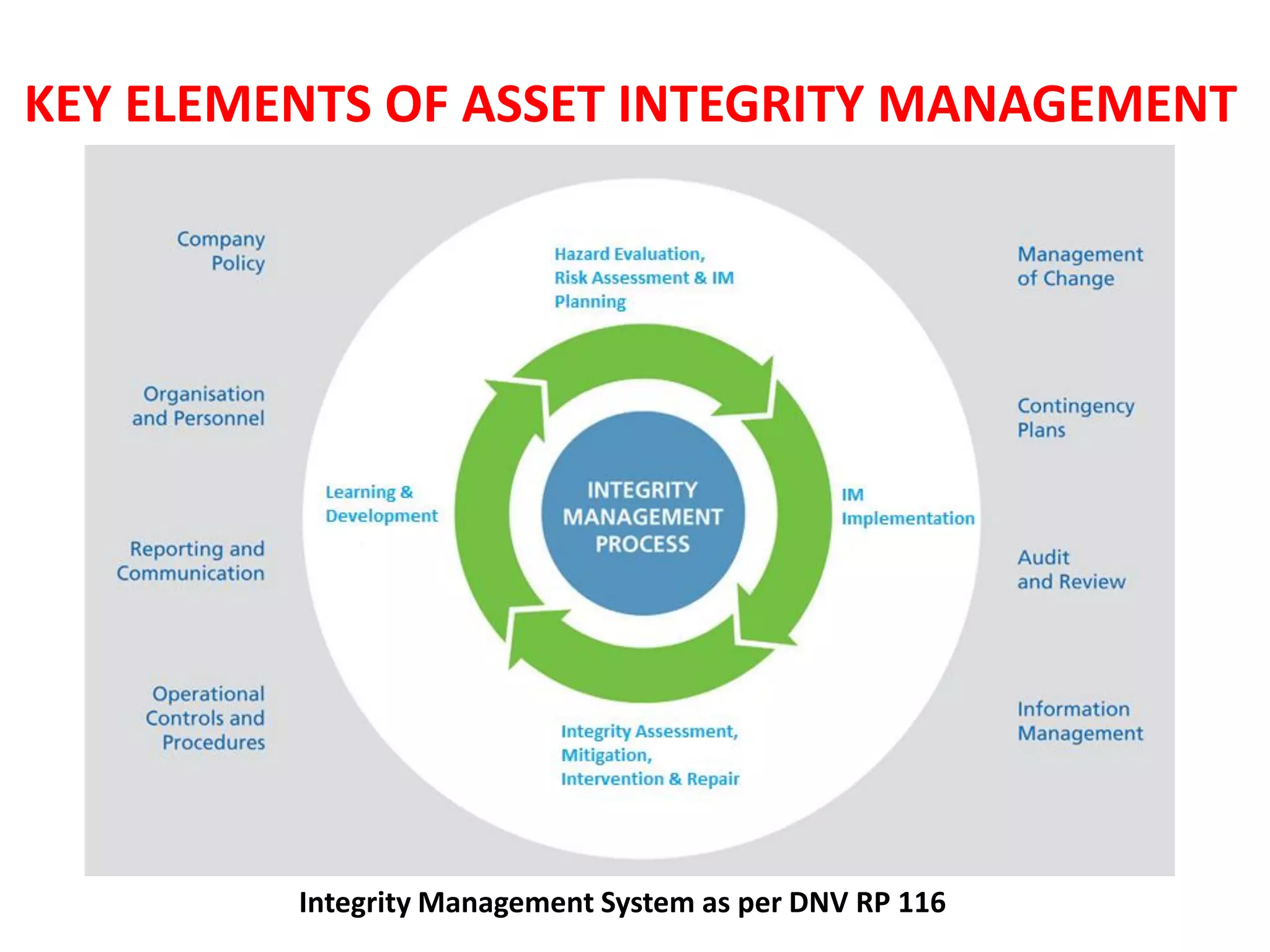

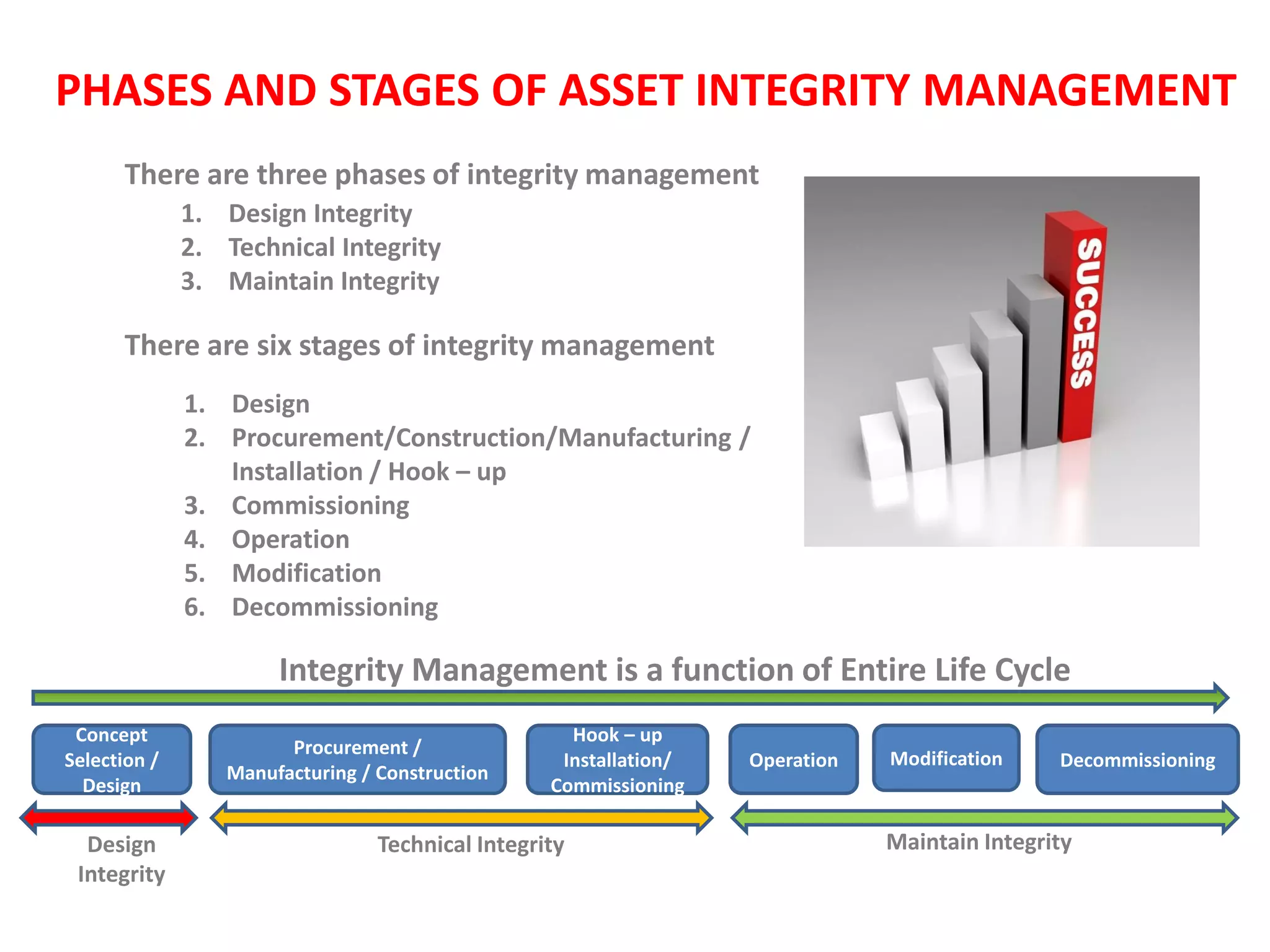

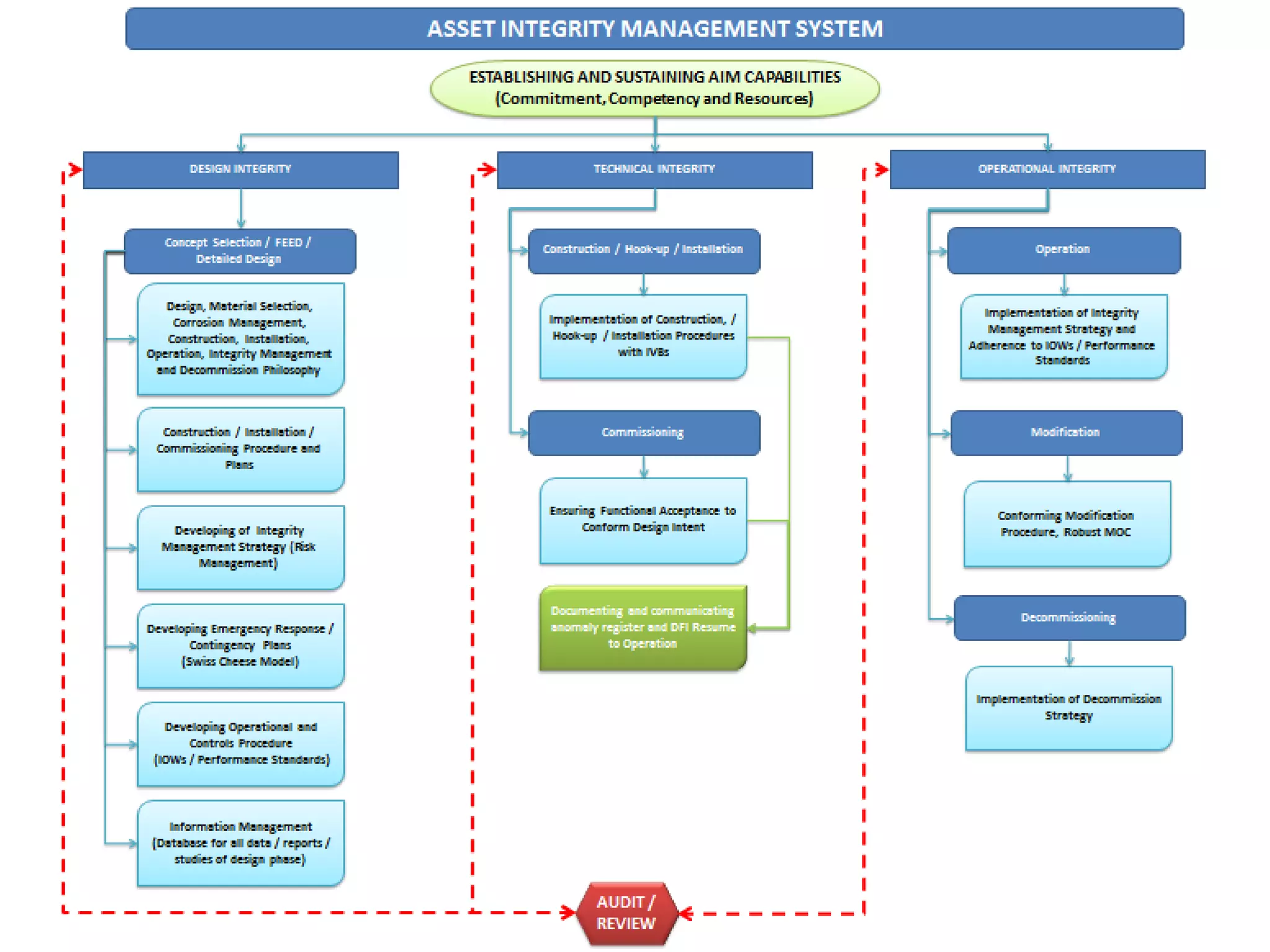

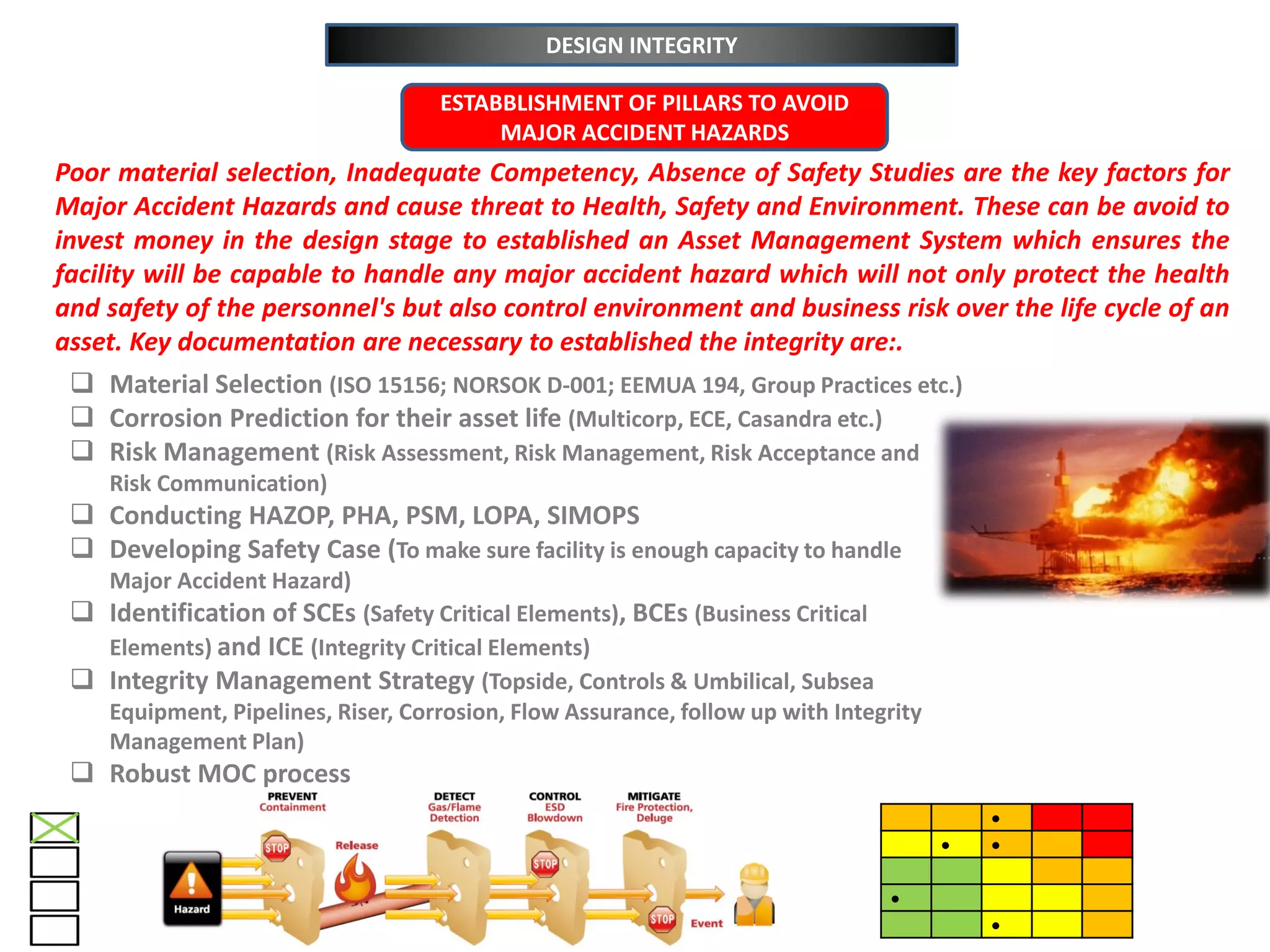

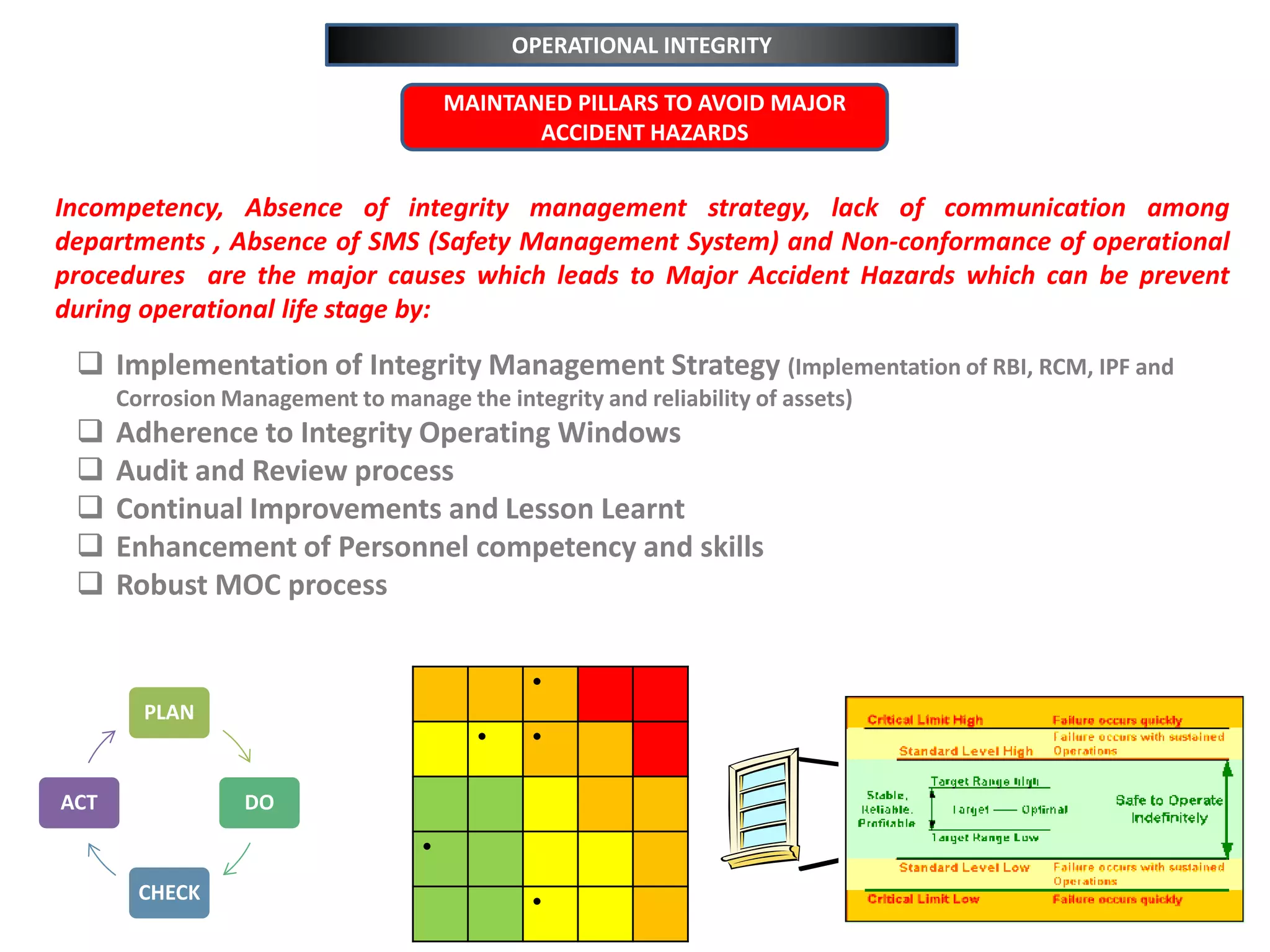

The document discusses asset integrity management and how major accidents can be prevented. It outlines key principles like being holistic, systematic, risk-based, and sustainable. Major accident hazards often result from incompetency, poor design, lack of barriers or management systems, and operating outside limits. The document emphasizes establishing pillars of integrity from design through operation to maintain technical and operational integrity. This includes robust documentation, standards, management strategies, and continual improvement to avoid incidents like Piper Alpha and Deepwater Horizon.