HAZOP ANALYSIS

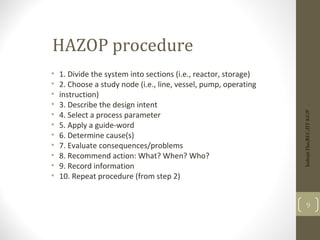

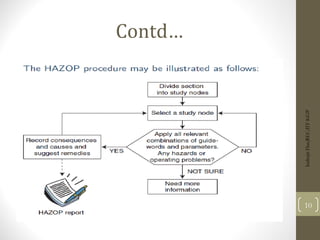

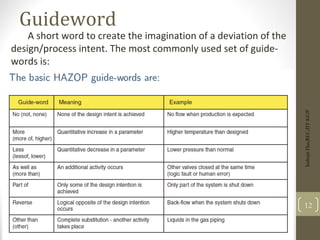

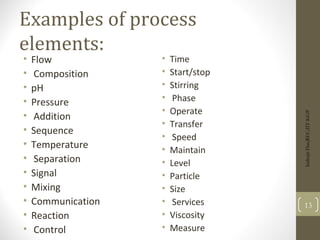

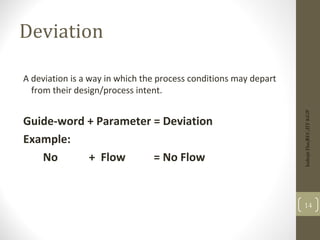

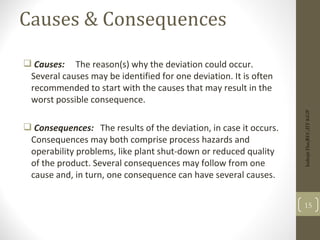

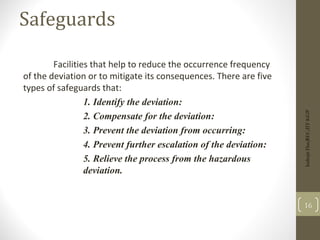

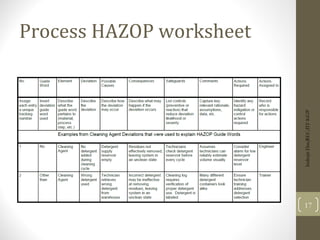

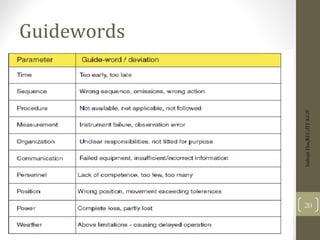

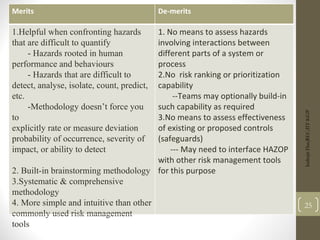

A Hazard and Operability (HAZOP) study is a systematic technique used to identify potential problems in processes. It involves examining a system and considering how intended design can deviate. A multidisciplinary team applies guidewords to parameters at nodes to identify causes and consequences of deviations. The team then recommends safeguards. HAZOP is useful early in design and can be applied to processes, procedures, software and human factors. It provides a structured way to brainstorm hazards without requiring quantification of risks.