Embed presentation

Downloaded 537 times

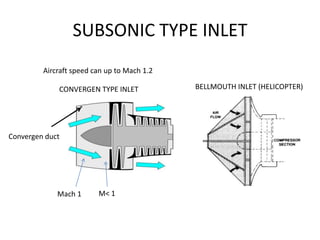

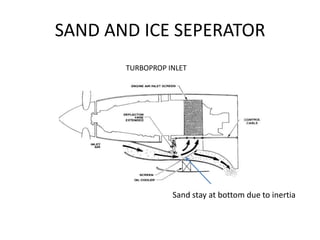

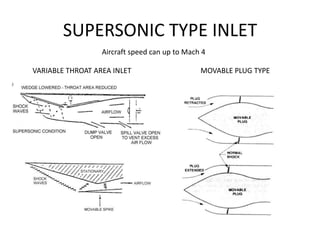

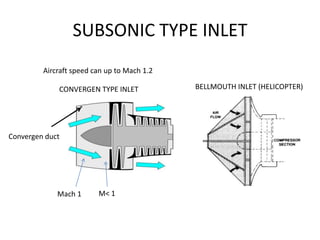

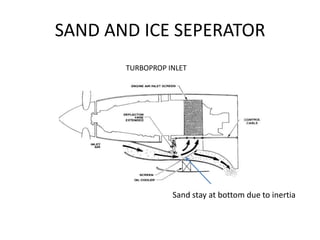

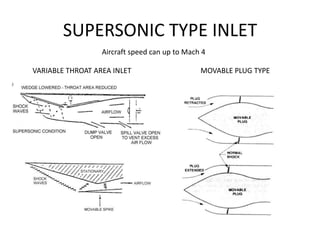

The document discusses different types of aircraft inlets. It describes subsonic and convergent inlets that can handle speeds up to Mach 1.2, as well as supersonic inlets that can handle speeds up to Mach 4. It also discusses inlet features like sand and ice separators. The document outlines common ice protection systems, including hot air, electrical, and hot oil systems, to prevent ice buildup that could disrupt airflow.