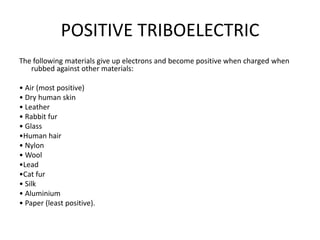

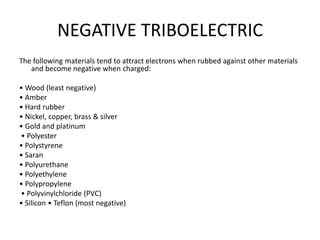

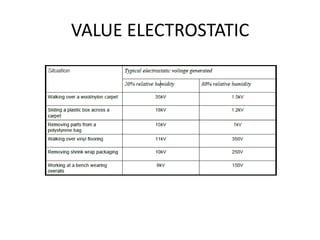

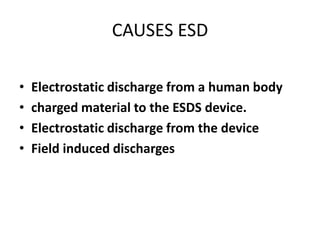

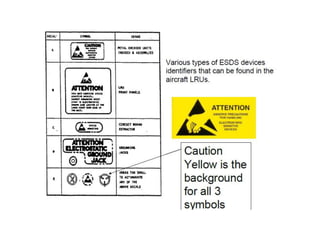

Electrostatic sensitive devices (ESD) are vulnerable to damage from electric charges, necessitating careful handling, storage, and transportation. The document details the process of triboelectric charging, lists positive and negative triboelectric materials, and outlines precautions for handling ESD equipment, such as using wrist straps and anti-static packaging. Proper practices are essential to prevent electrostatic discharge that can harm these sensitive components.