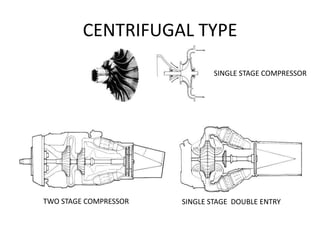

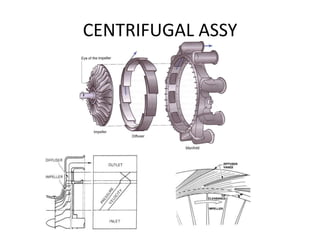

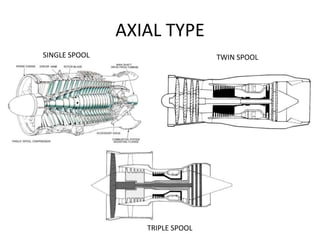

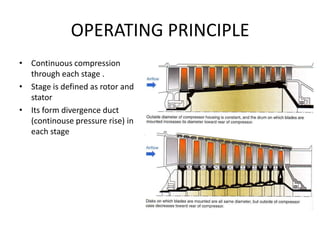

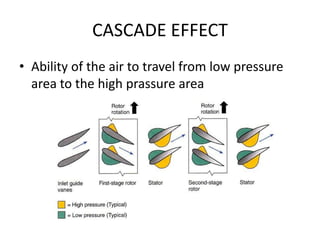

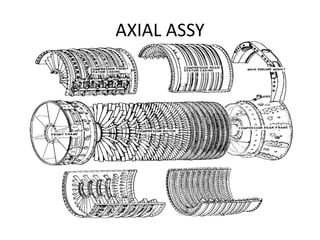

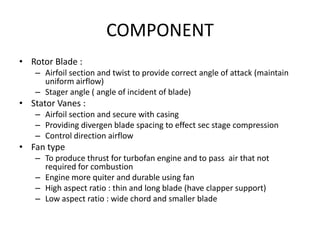

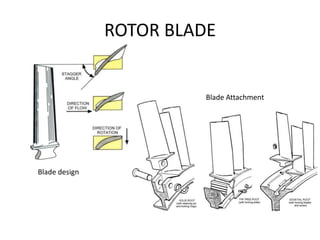

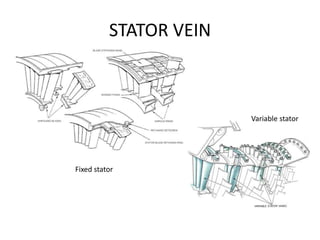

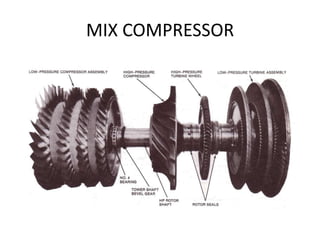

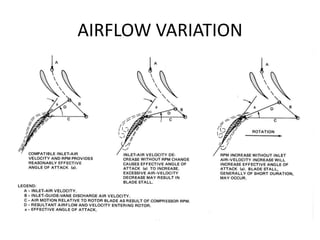

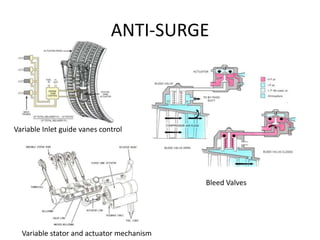

Centrifugal and axial compressors are the two main types used in aircraft jet engines. Centrifugal compressors have advantages like being cheap and resistant to foreign object damage, but have limitations like a lower compression ratio. Axial compressors can achieve higher compression ratios but are more complex and prone to stall and surge issues. Both compressor types work by continuously increasing the pressure of air through multiple compressor stages or rows of rotor blades and stator vanes. Anti-surge devices help control airflow and prevent compressor stall and surge.