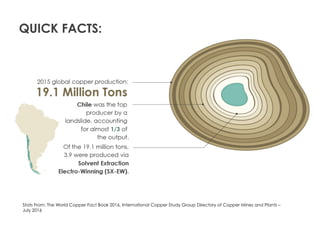

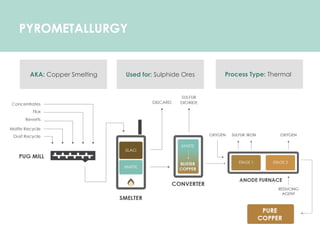

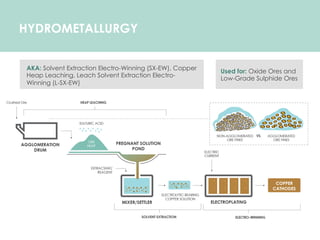

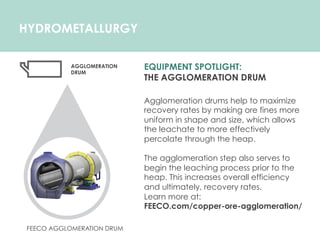

The document outlines the various methods of processing copper ore into refined products, highlighting pyrometallurgy for sulphide ores and hydrometallurgy for low-grade sulphide and oxide ores. It emphasizes equipment such as pug mills and agglomeration drums used to enhance efficiency in these processes. Additionally, the document promotes Feeco's expertise and custom solutions in copper processing over 65 years.