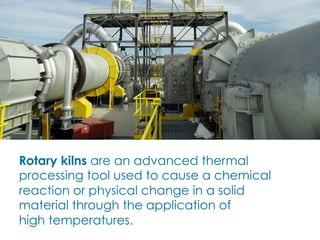

The document discusses the functions and advantages of rotary kilns, which have been used for over 65 years in thermal processing to cause chemical reactions or physical changes in materials. Key processes include calcination, thermal desorption, organic combustion, sintering, heat setting, and reduction roasting, each serving distinct industrial needs. The company provides comprehensive services in the thermal processing industry, including custom rotary kilns and related support.