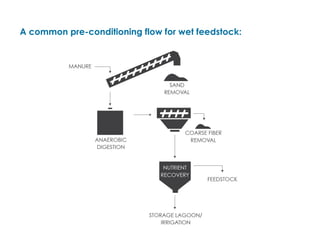

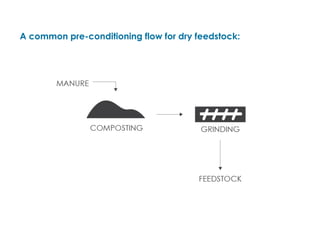

Manure pre-conditioning is necessary to prepare manure as a suitable feedstock for granulation into fertilizer. Pre-conditioning focuses on adjusting the particle size, moisture content, and composition of manure. For wet manures like dairy and hog manure, common pre-conditioning methods include sand removal, anaerobic digestion, coarse fiber removal, and solid/liquid separation. For dry manures like poultry litter, common methods include drying, grinding, and composting. The goal of pre-conditioning is to produce a homogenous feedstock with optimal properties for effective granulation.