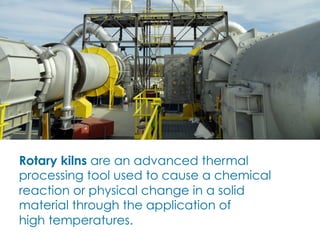

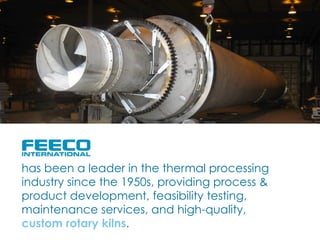

This document outlines the significance and applications of rotary kilns in thermal processing, highlighting their flexibility to handle various materials and the essential role of testing in process design. It details the importance of testing for commercial viability, product development, and improving existing processes, while describing different testing phases—batch and pilot testing. The Feeco Innovation Center is introduced as a facility offering comprehensive testing options and data collection to optimize rotary kiln processes.