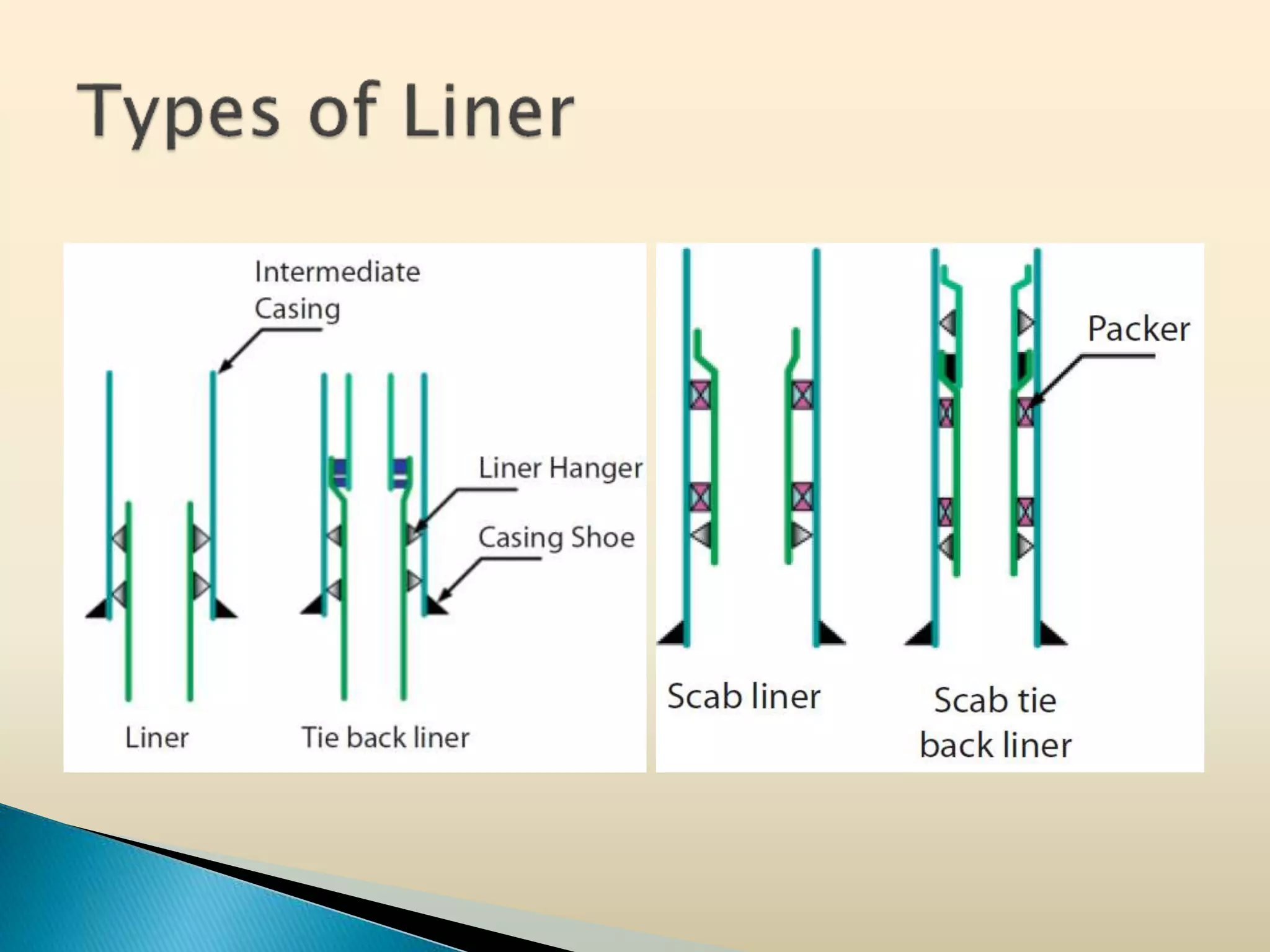

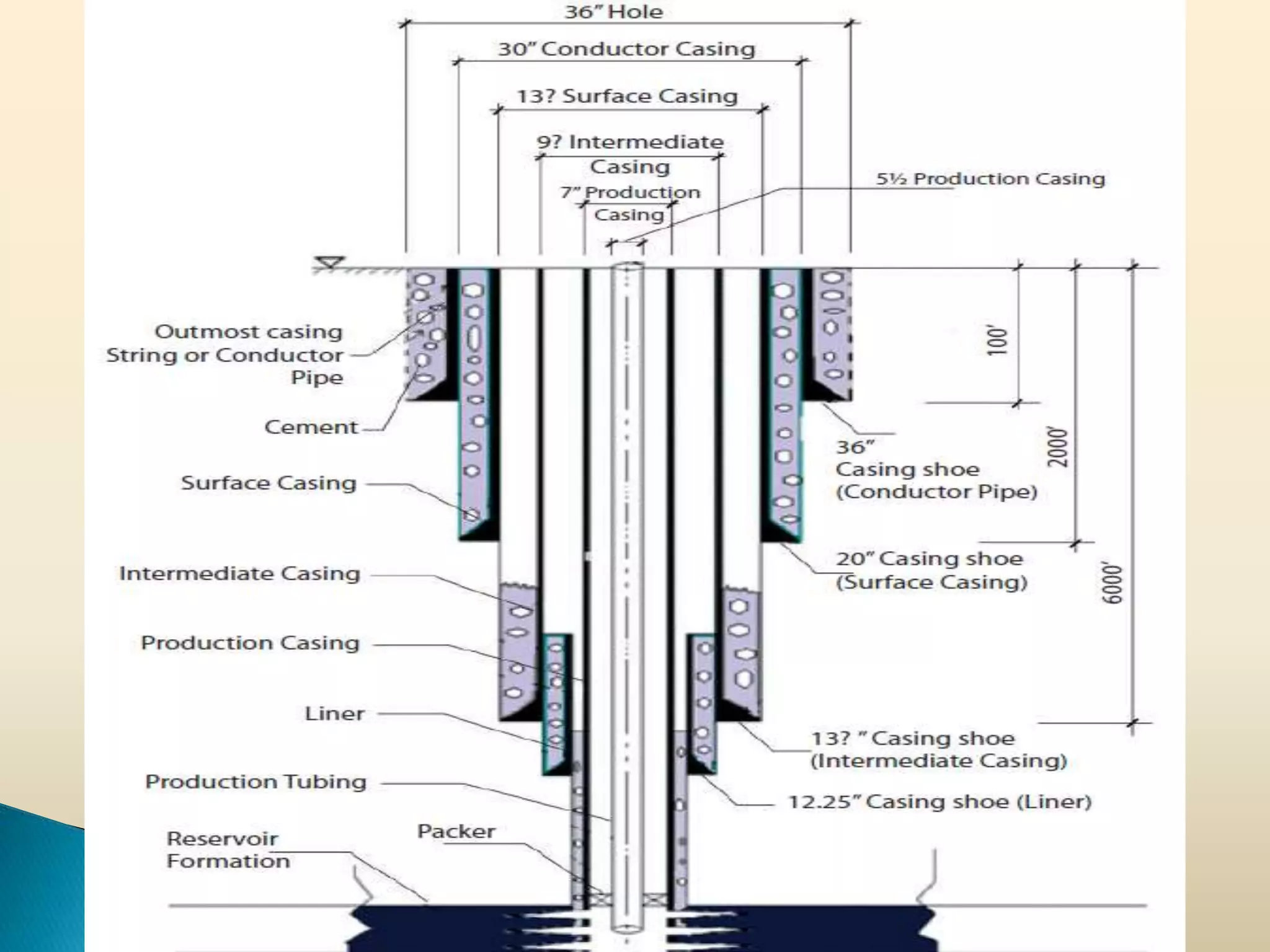

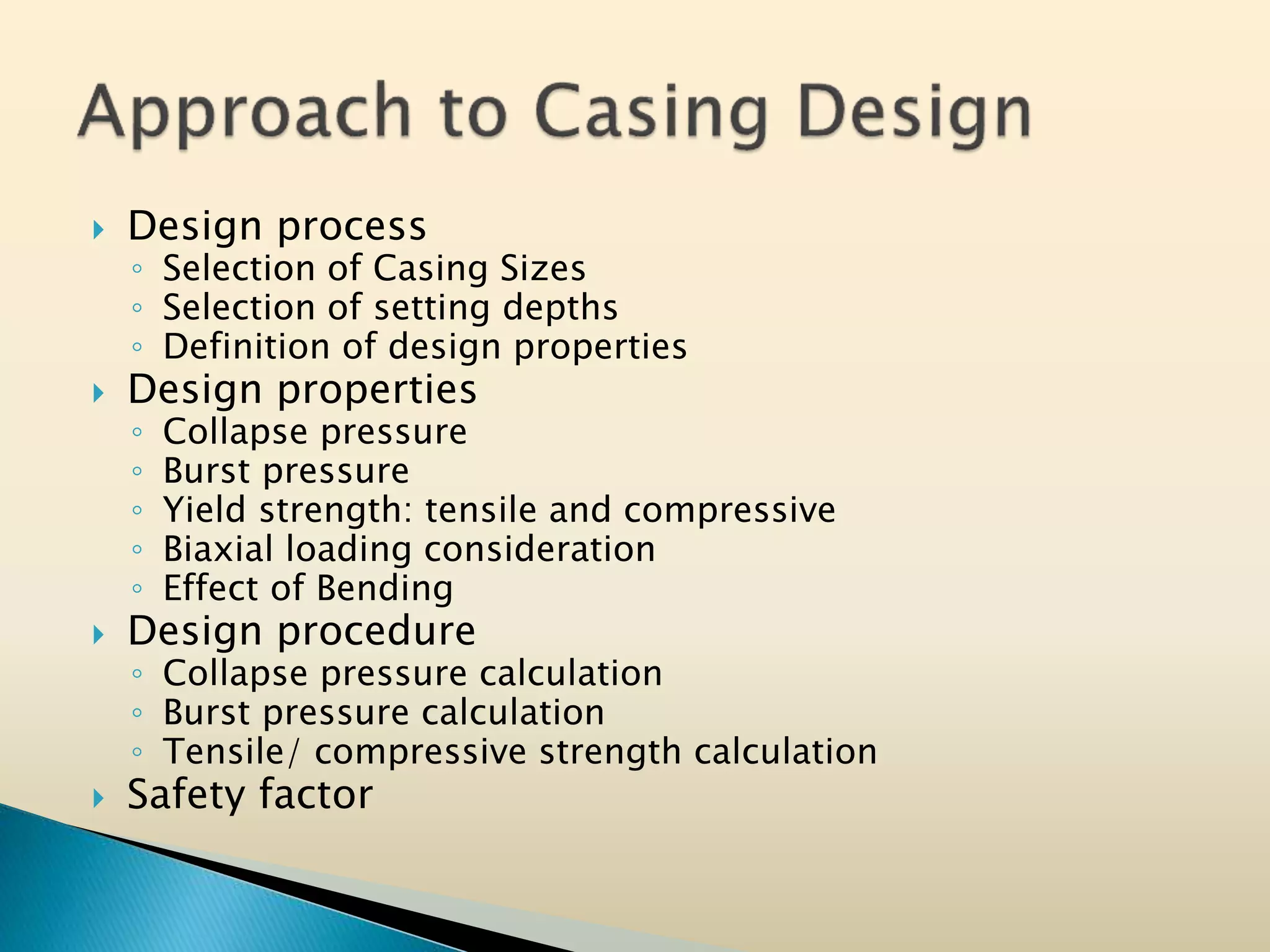

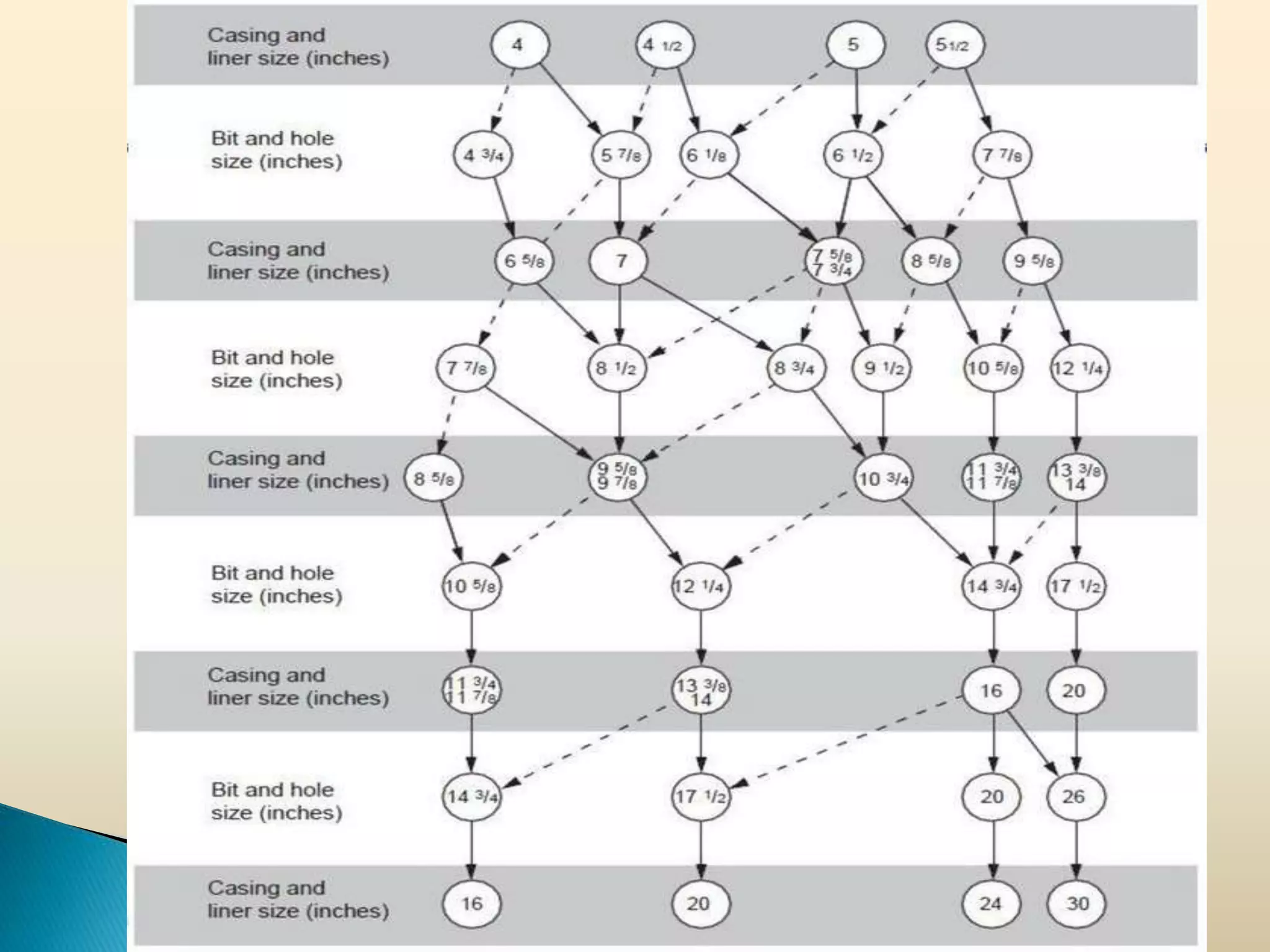

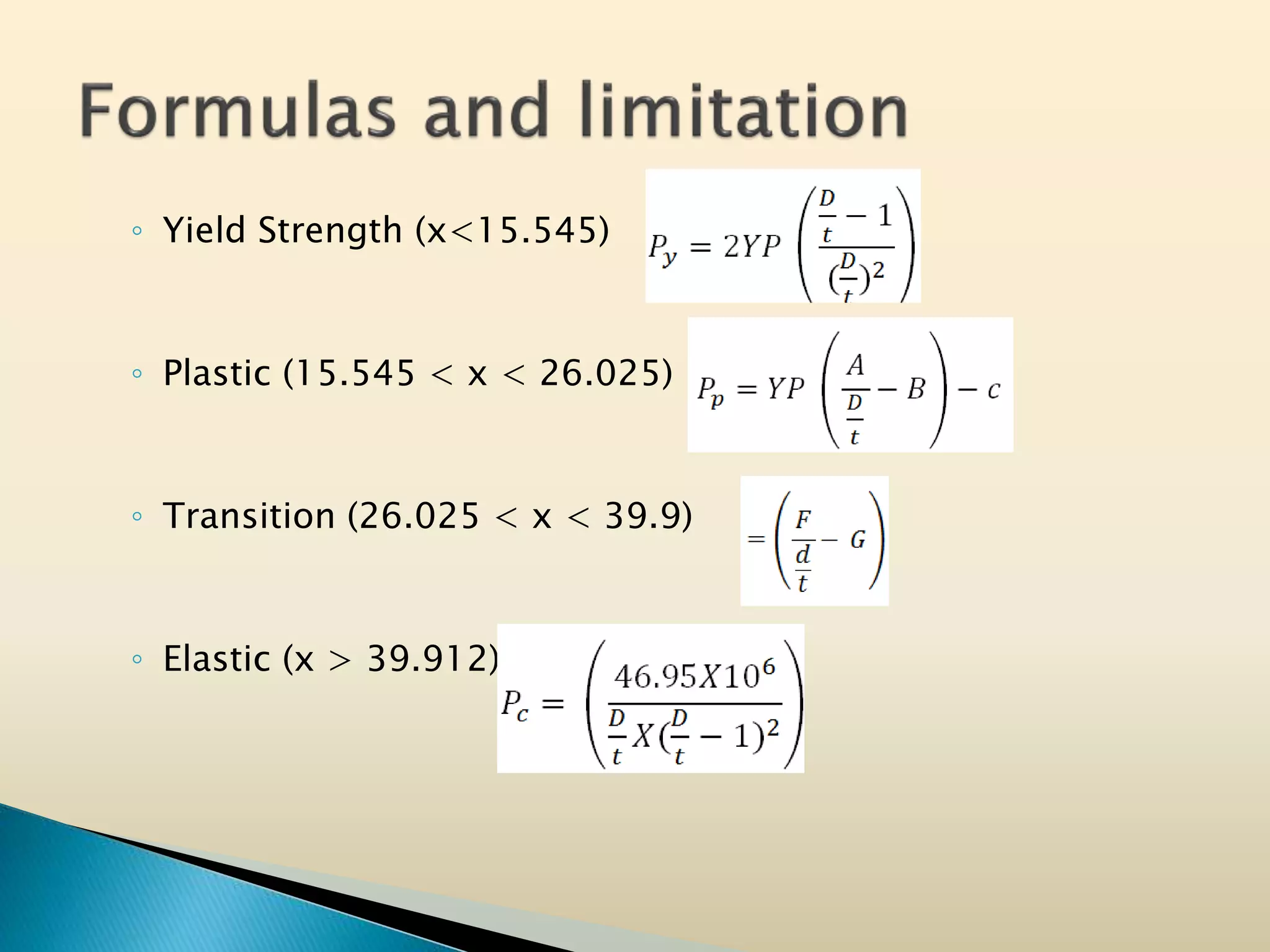

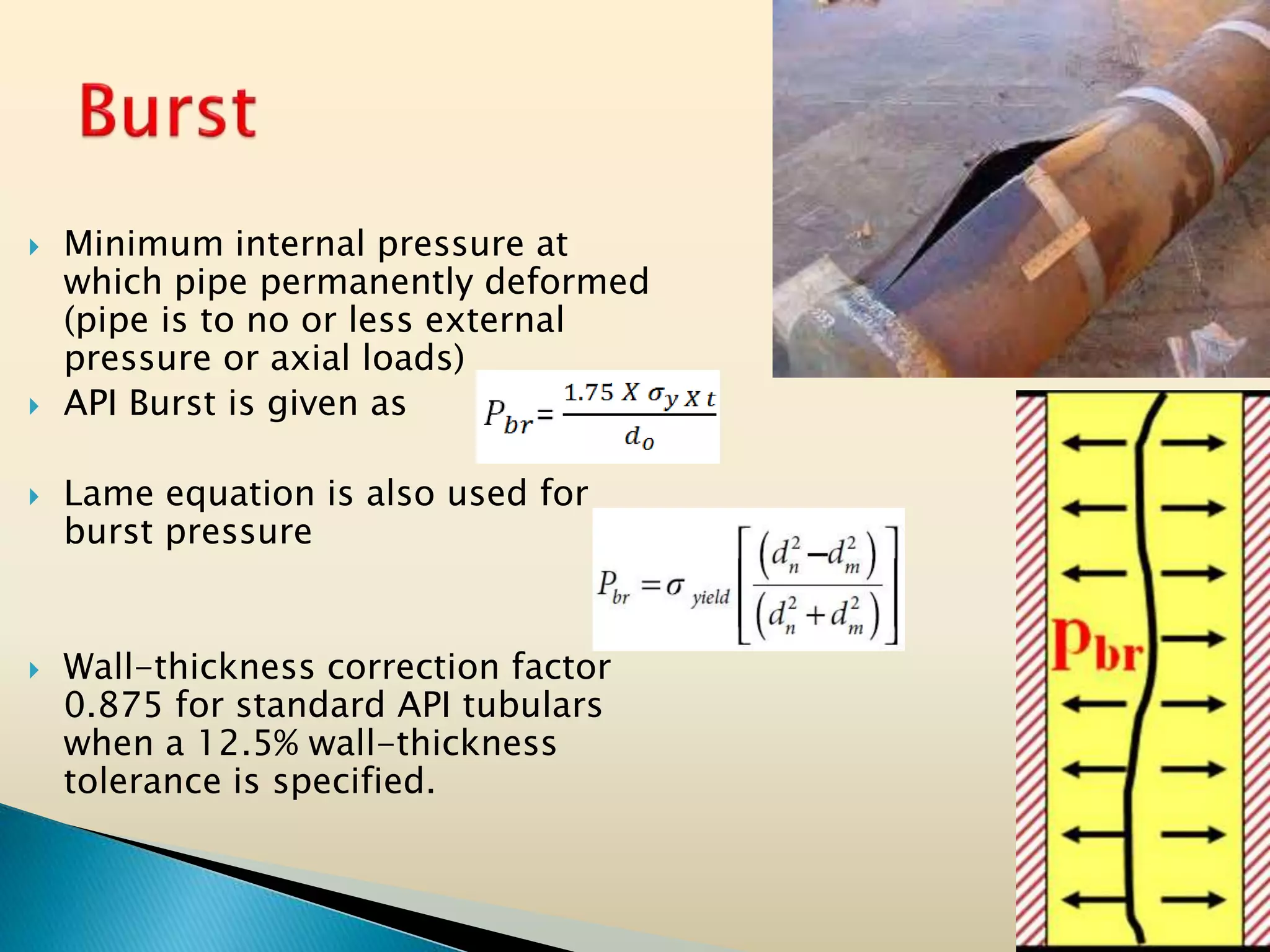

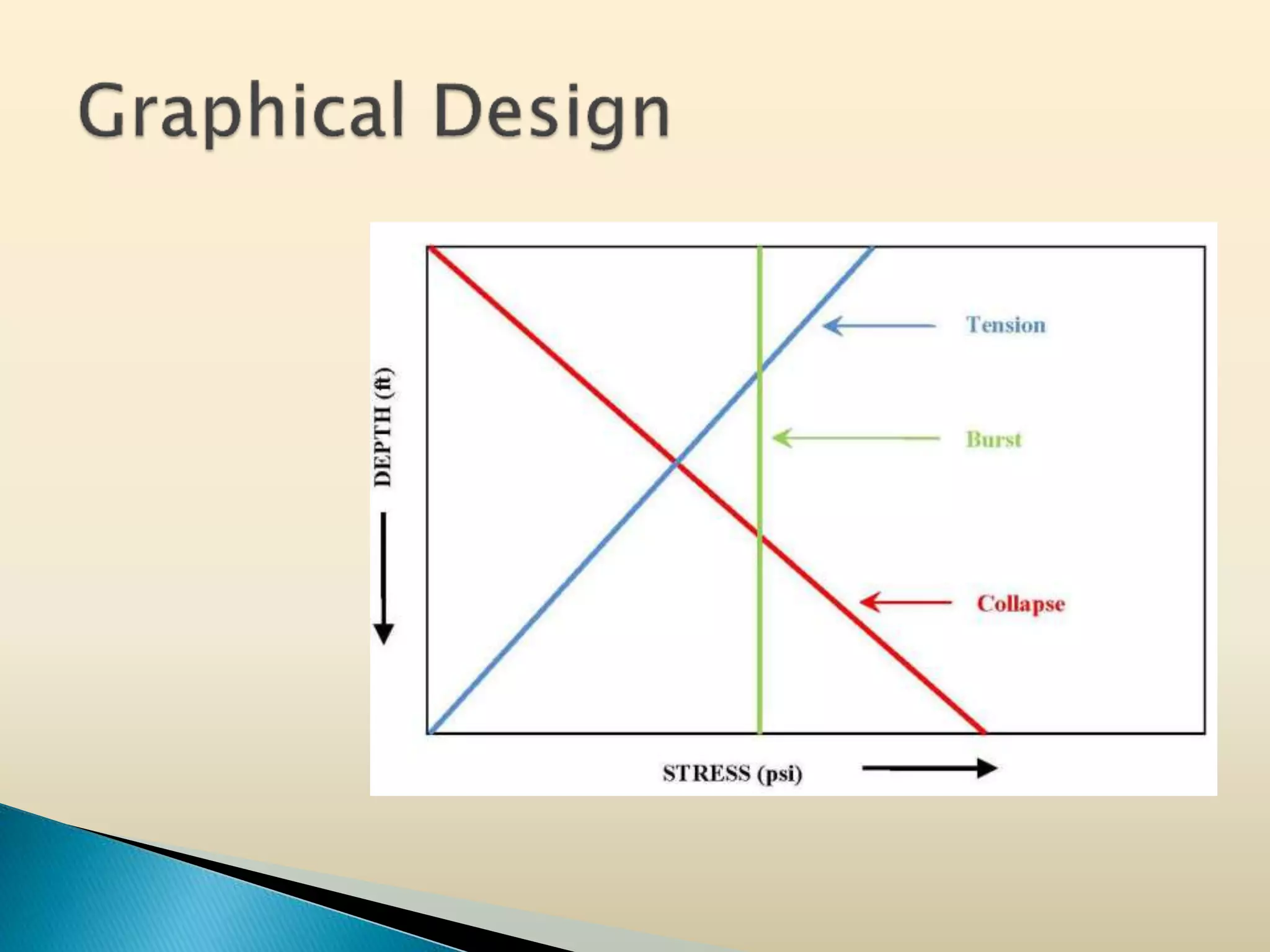

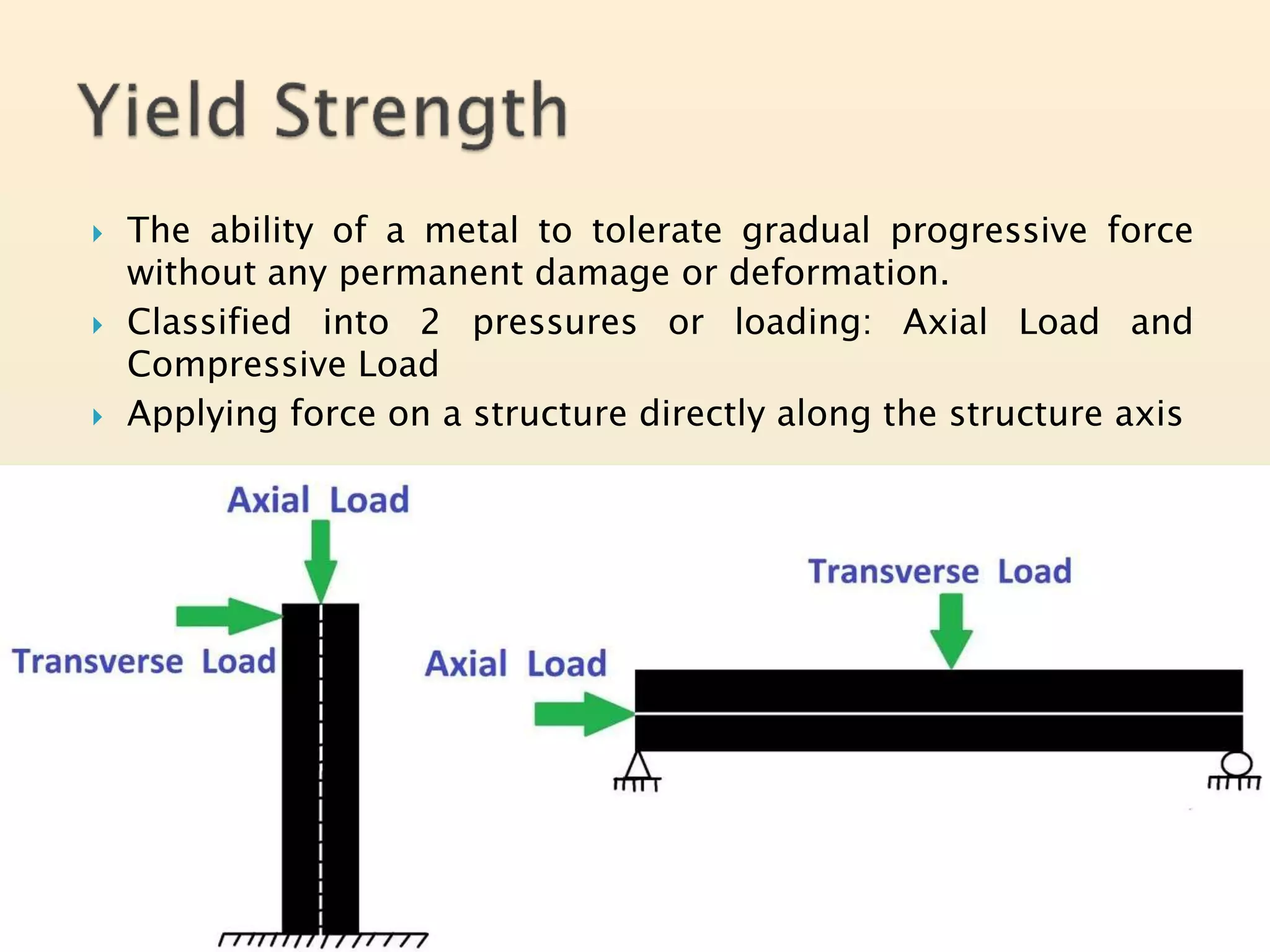

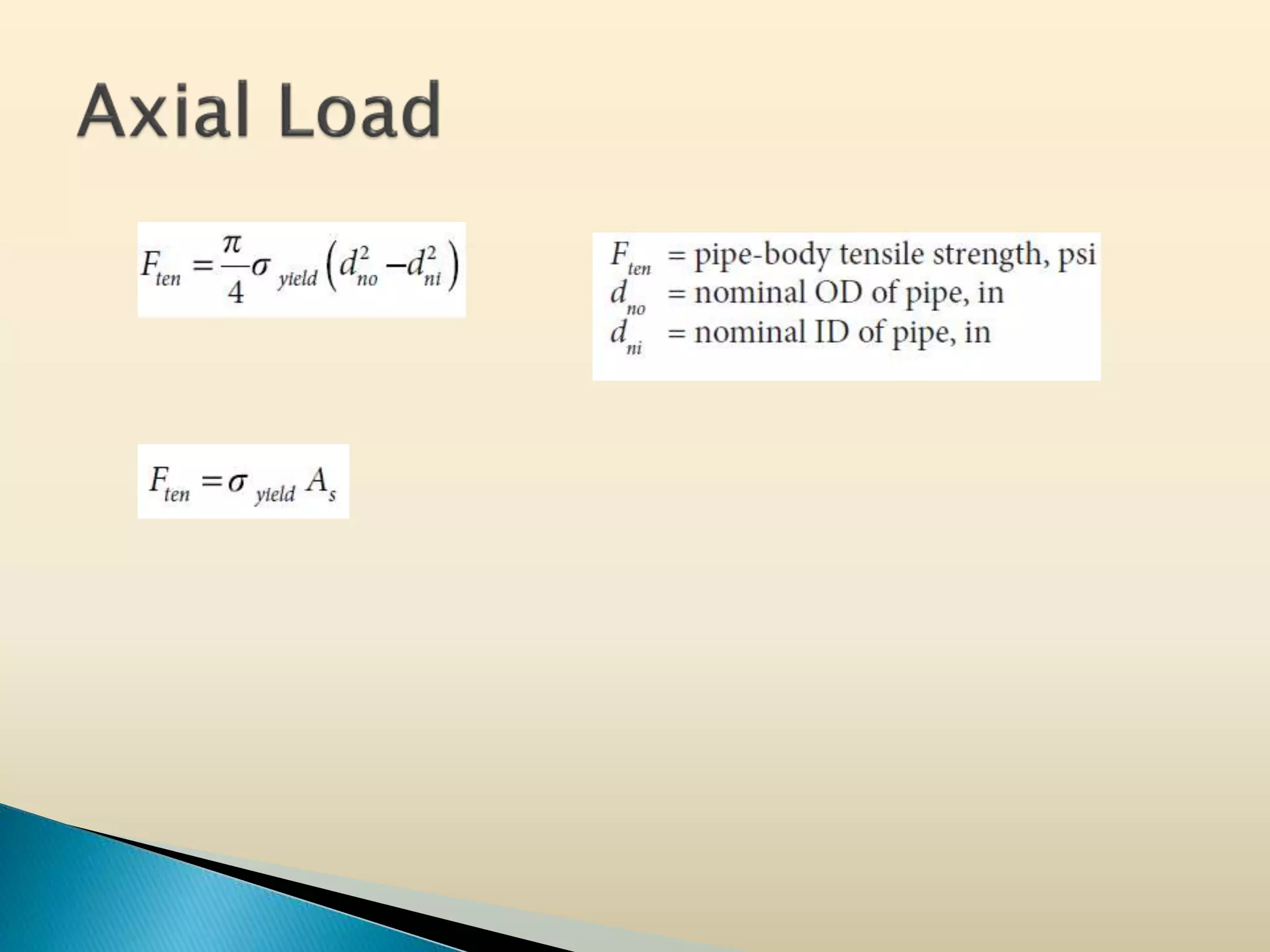

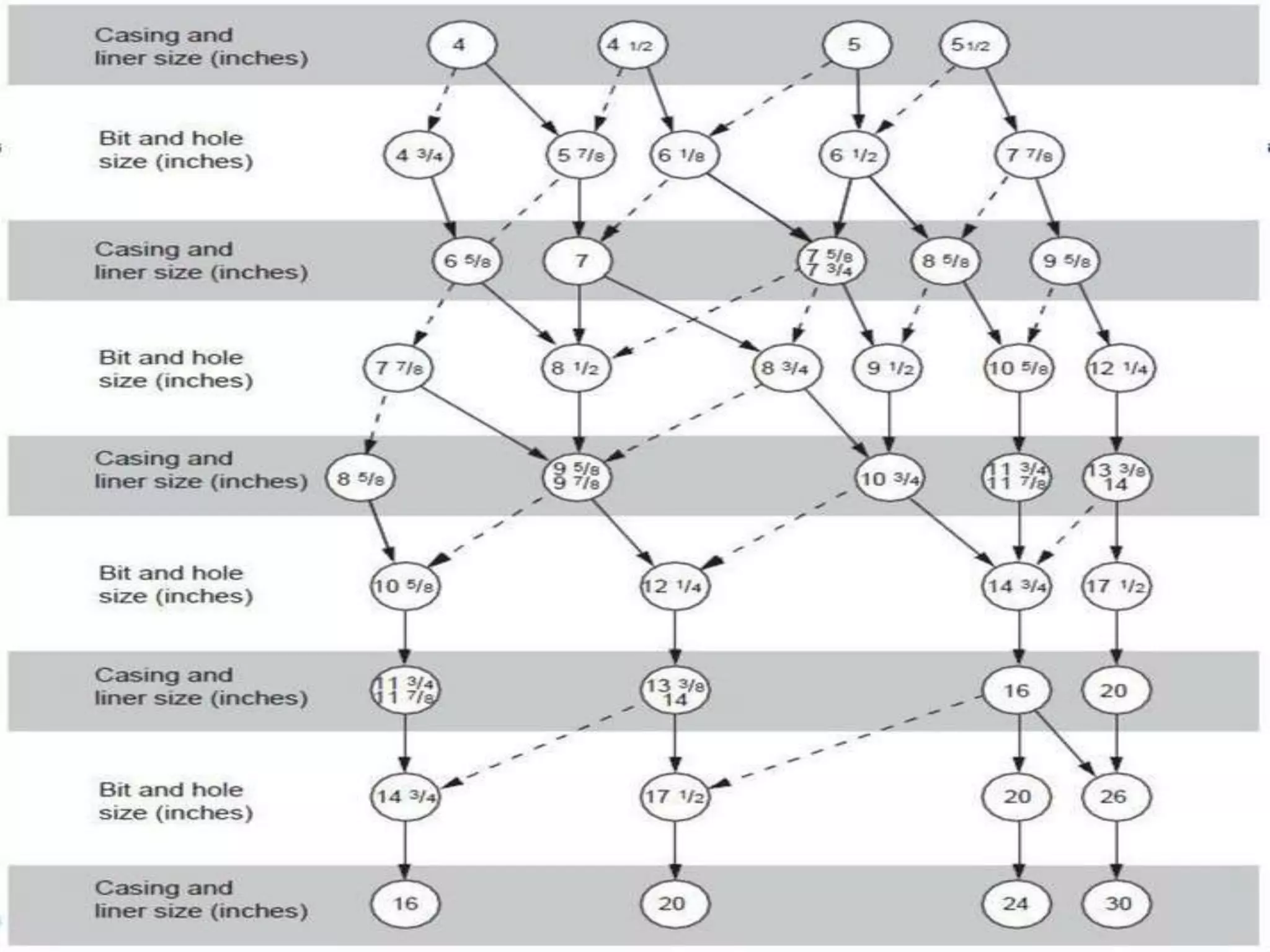

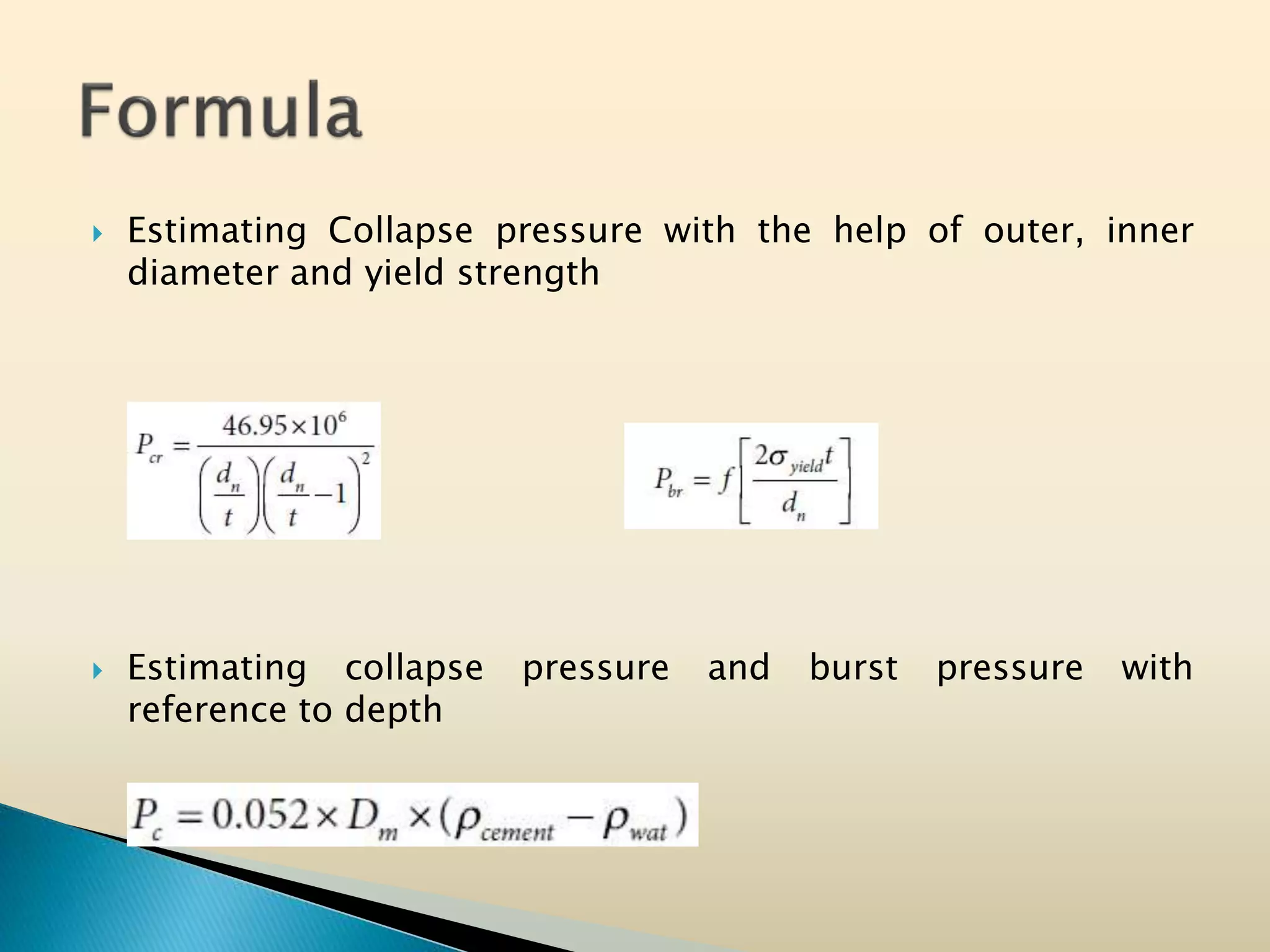

The document, authored by Syed Nawaz, discusses the essential functions, types, and design considerations of casing in well construction. It outlines specifications for different casing types, their installation purposes, and safety factors regarding collapse and burst pressure in drilling operations. The summary includes references to relevant literature and formulas critical for calculating casing performance under various conditions.