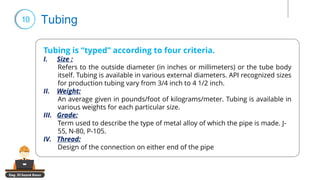

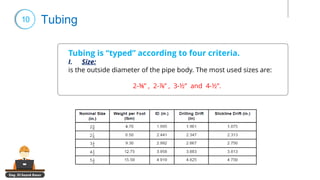

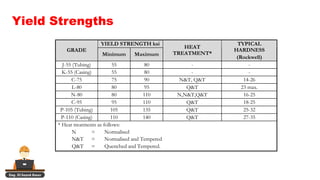

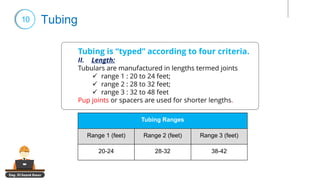

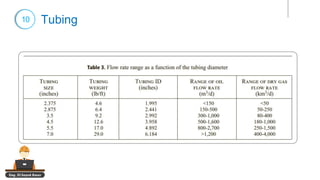

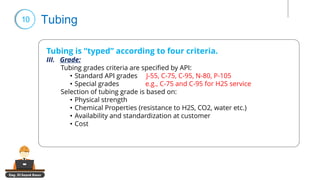

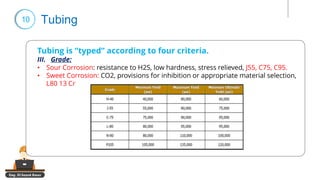

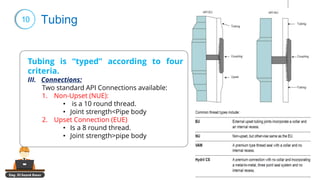

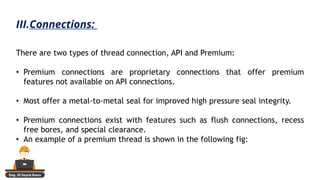

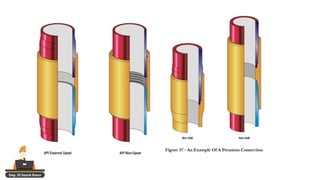

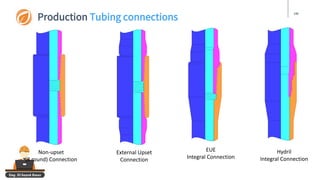

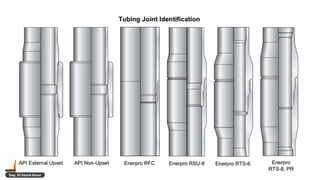

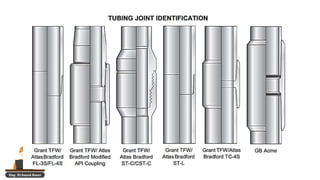

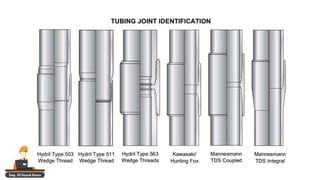

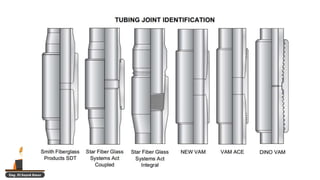

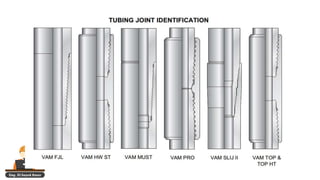

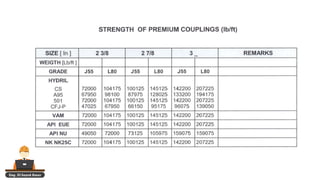

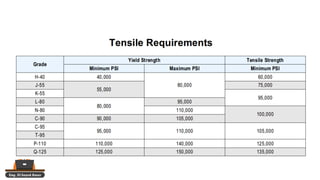

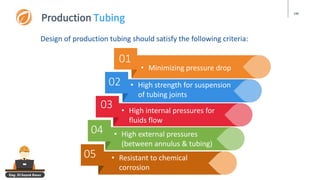

Production tubing is installed in oil and gas wells to allow hydrocarbons to flow from the reservoir to the surface while protecting the casing from reservoir fluids. Tubing is specified based on its size, length, grade, and connection type. Common tubing sizes range from 2-3/8" to 4-1/2" in diameter. Tubing joints are typically 20-48 feet in length. Tubing grade depends on the application and is chosen based on strength, corrosion resistance, and availability. Connections can be either upset or non-upset threaded types.