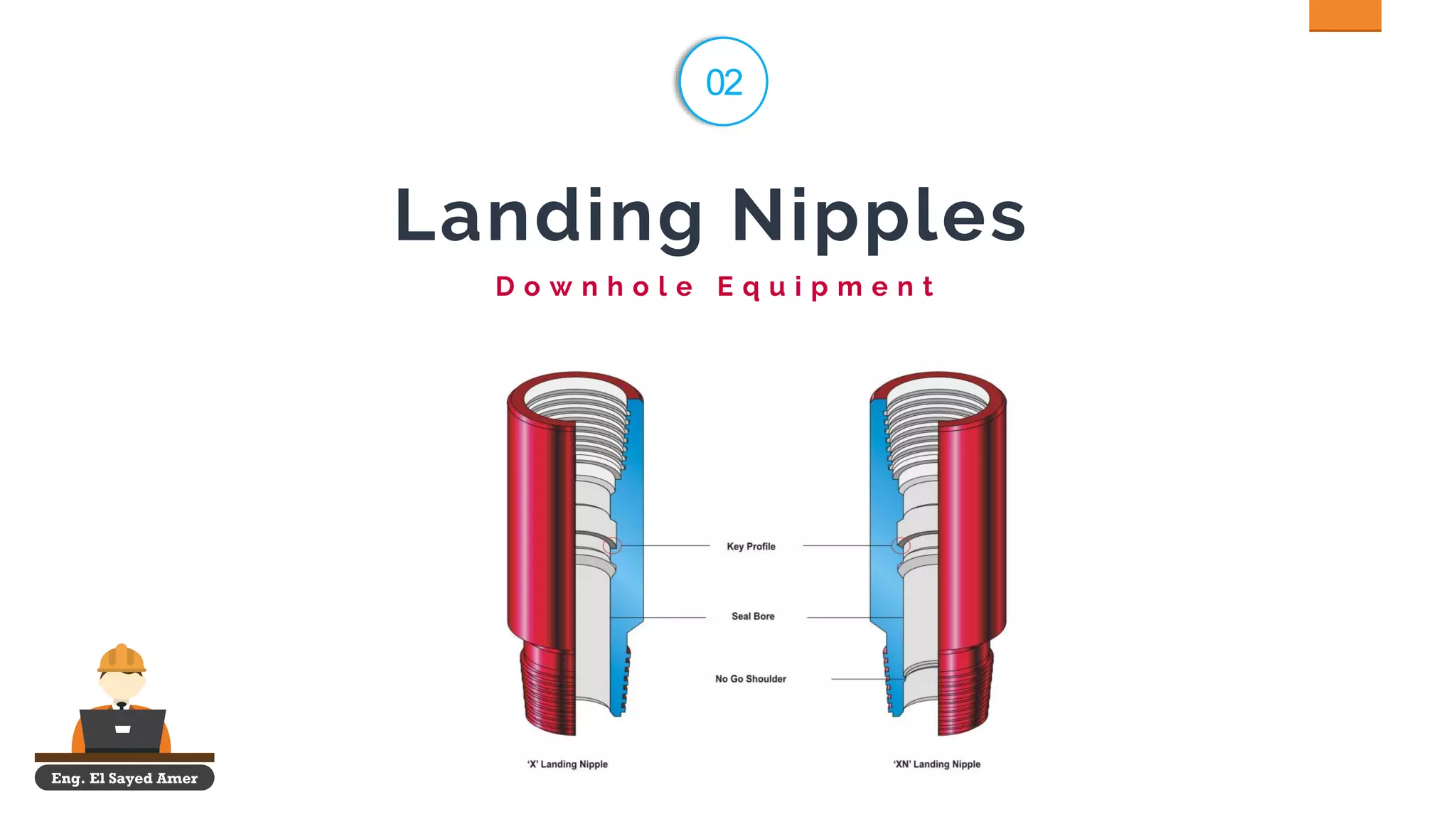

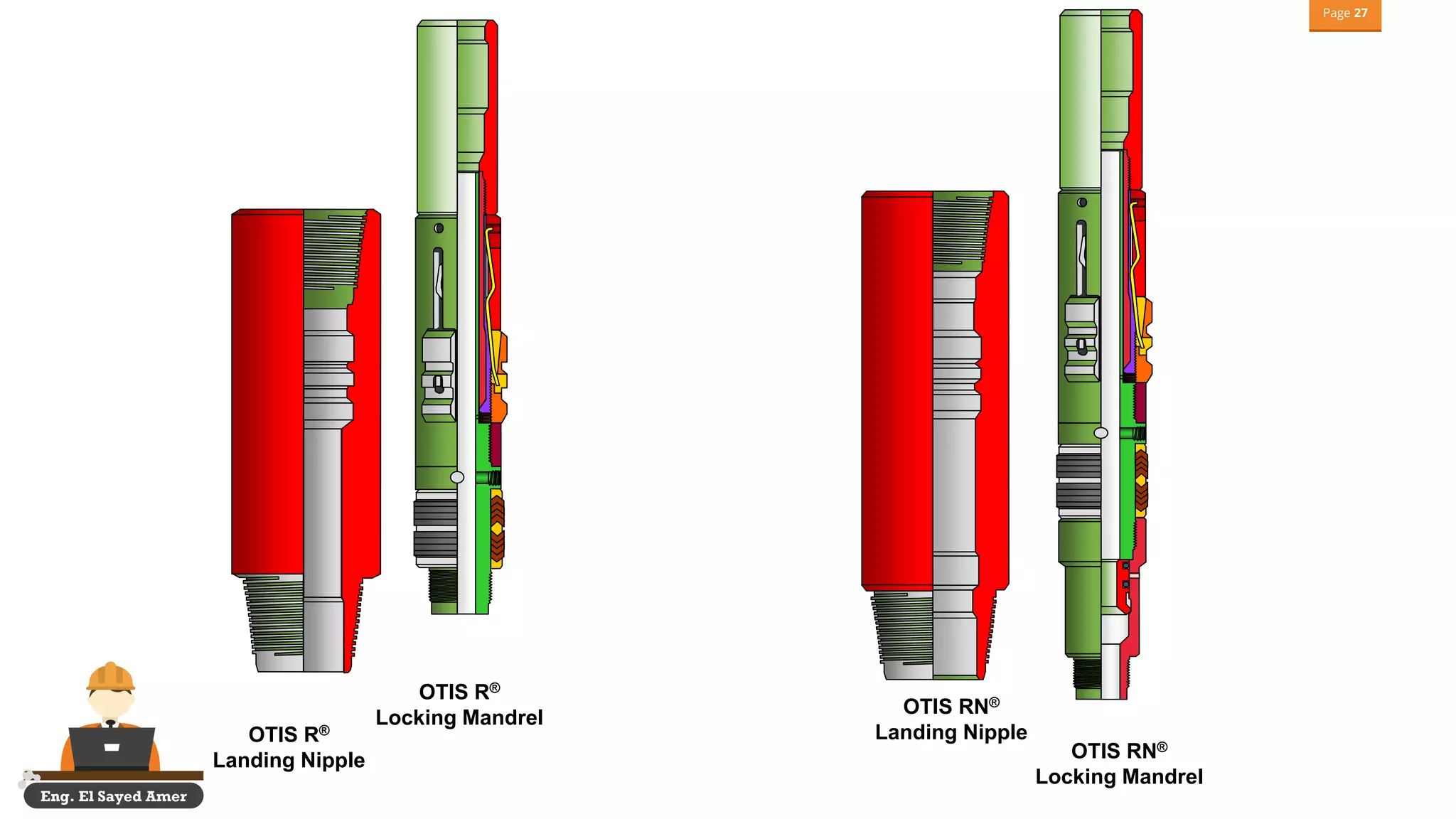

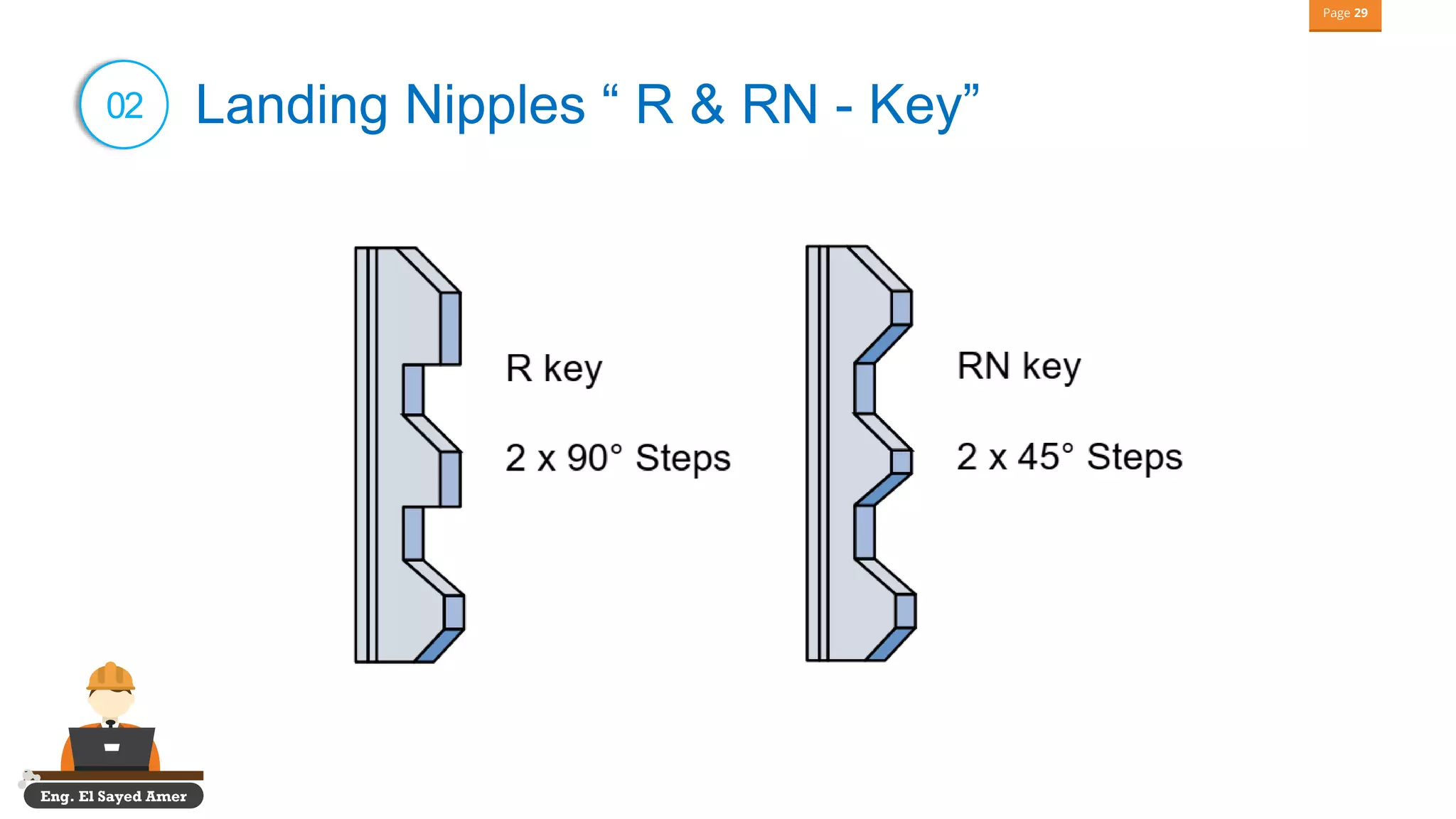

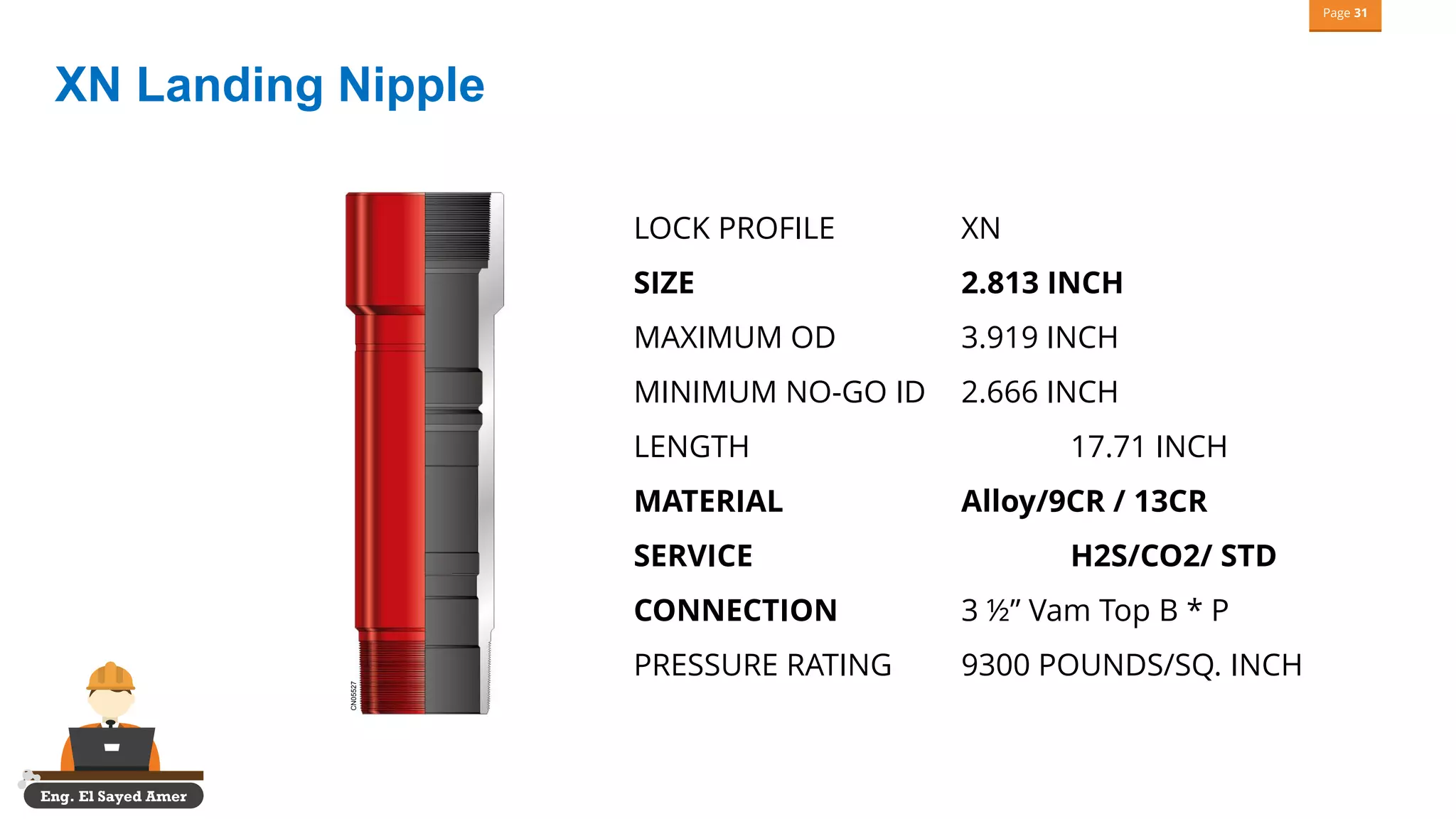

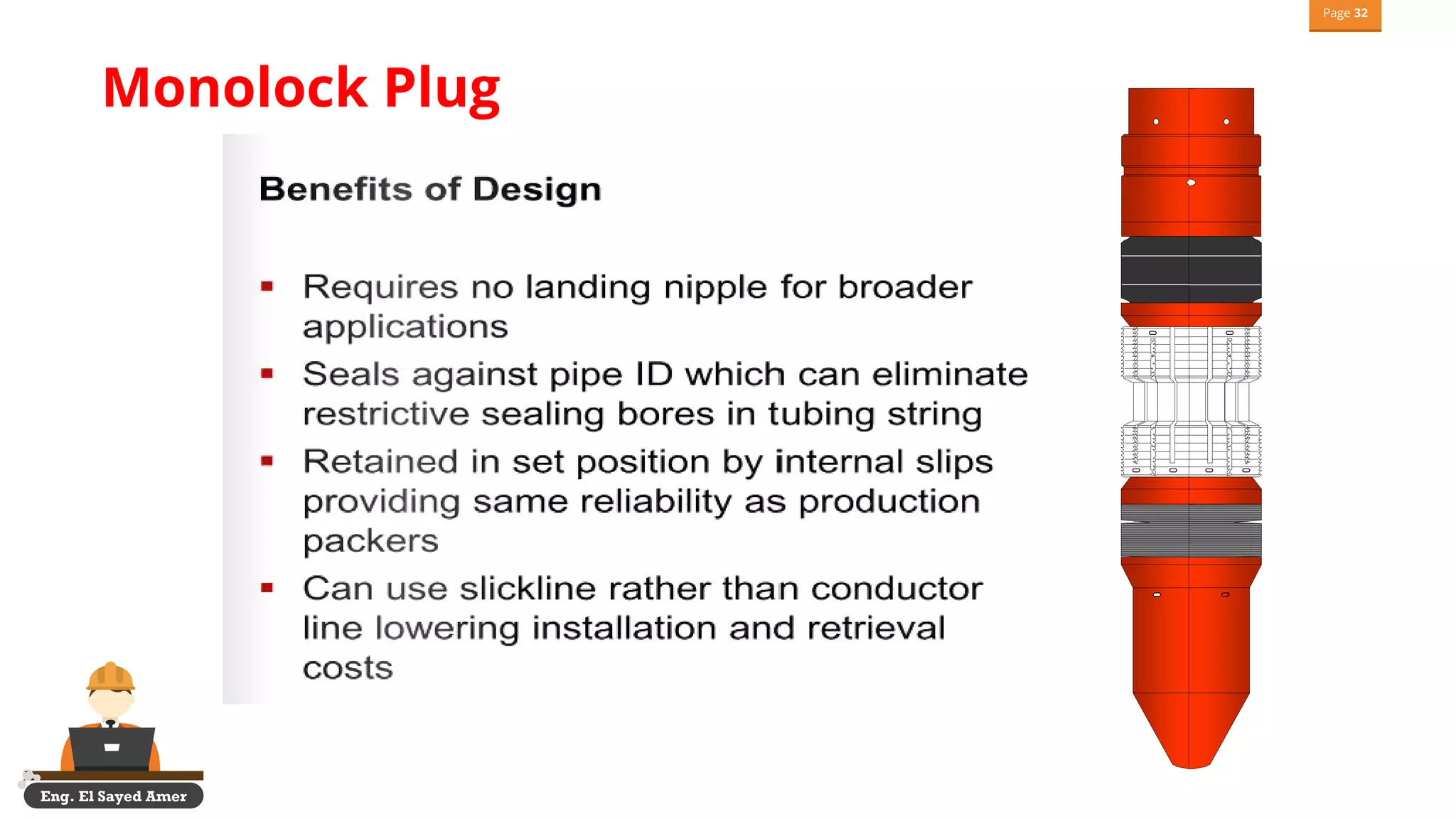

Landing nipples are short pieces of pipe with internal profiles that allow lock mandrels to locate and lock into them. They are used to plug tubing for various well operations like removing equipment, pressure testing, and setting packers. The main types are selective and no-go nipples. A typical slickline plug consists of a lock mandrel, equalizing sub, and flow control device. Major manufacturers include Baker, CAMCO, Halliburton/Otis, and Weatherford CPS/Petroline.