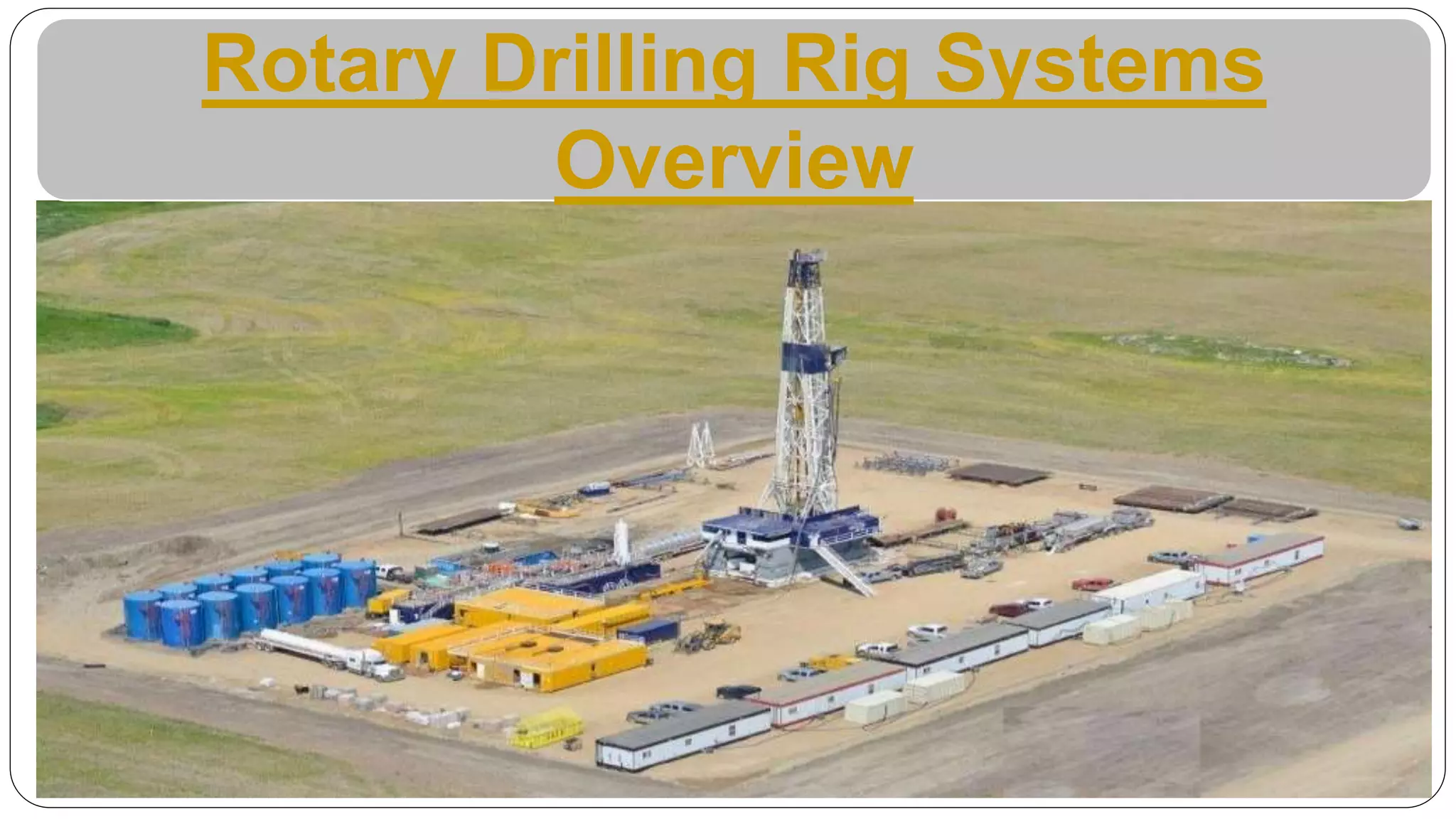

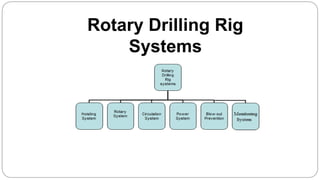

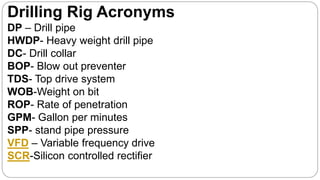

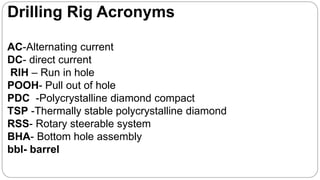

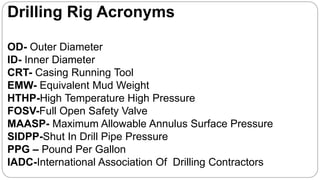

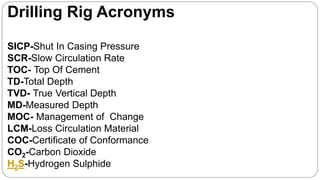

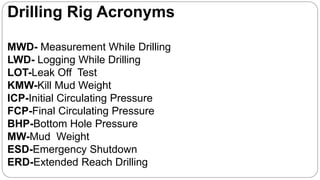

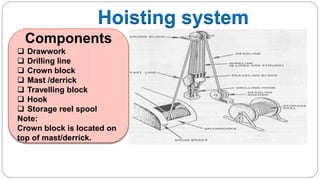

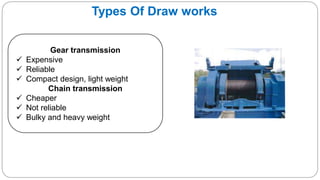

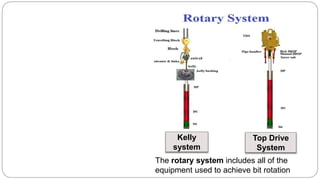

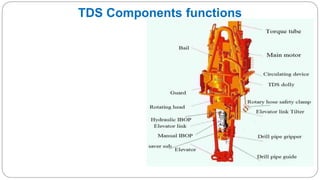

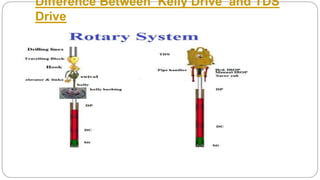

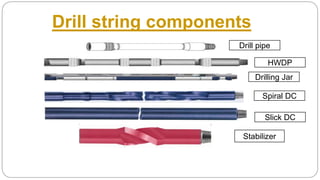

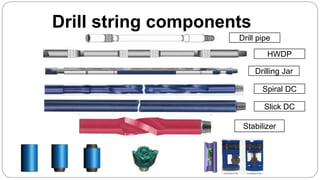

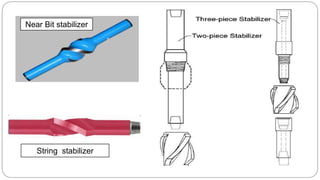

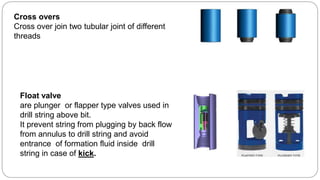

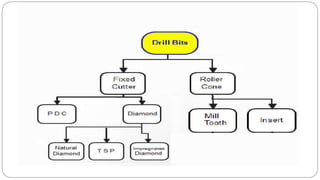

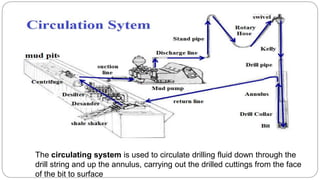

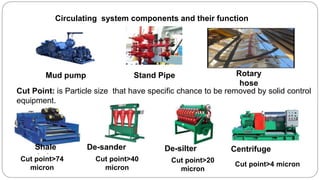

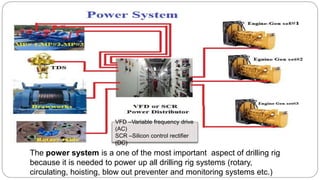

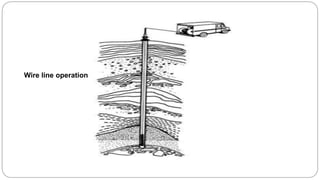

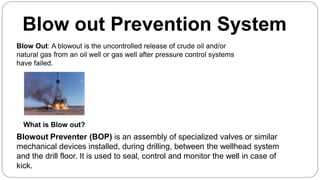

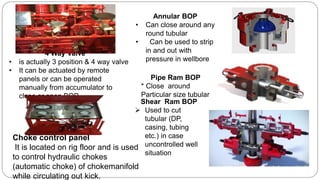

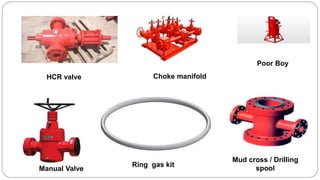

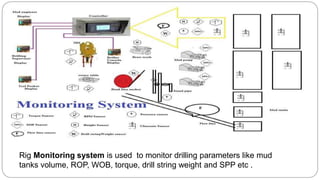

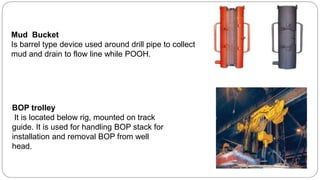

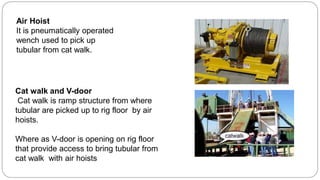

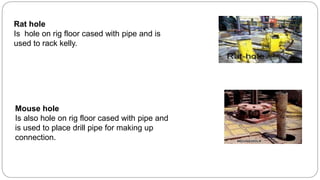

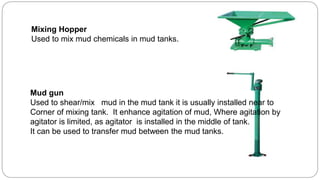

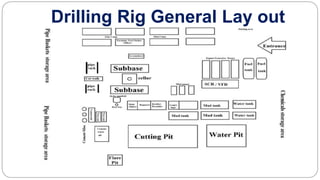

This document provides an overview of rotary drilling rig systems and components. It defines what a drilling rig is and lists various acronyms used in drilling operations. It describes the major systems on a drilling rig including the hoisting system, rotary system, circulating system, power system, blowout prevention system, and monitoring systems. It also summarizes key components that make up each system such as the drawworks, drill pipe, kelly, blowout preventers, mud pumps, shale shakers, and monitoring equipment. Miscellaneous rig equipment is outlined including the rig floor, pipe handling tools, mud tanks, and rig layout. Online courses for drilling rig training are mentioned at the end.