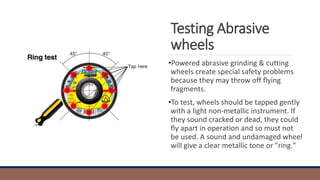

This document provides safety guidelines for using hand and power tools. It discusses regulations covering hand and power tools and lists general safety precautions. Hand tools are non-powered and pose hazards from misuse or improper maintenance. Power tools require more care as they offer more power and should only be operated according to manufacturer's instructions with proper protective equipment. The document also provides testing and safety procedures for abrasive wheels, power tools, and pneumatic tools.