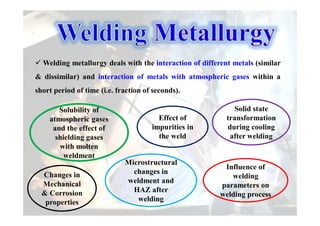

This document discusses various topics related to welding metallurgy including:

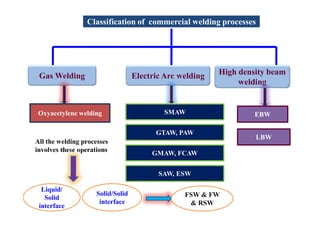

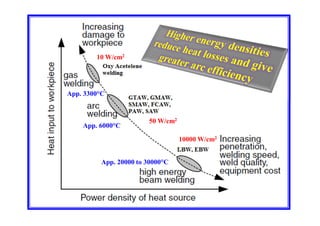

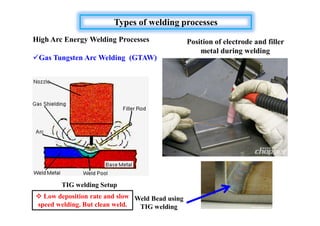

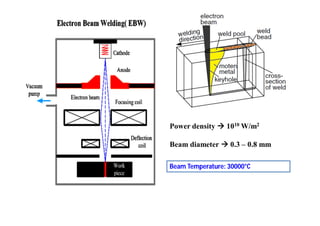

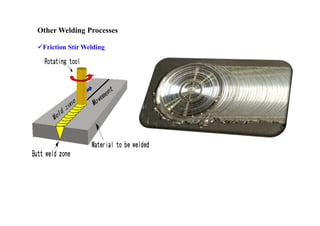

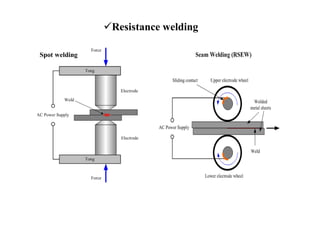

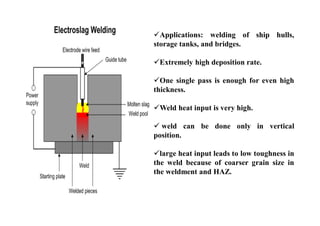

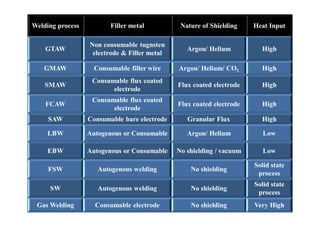

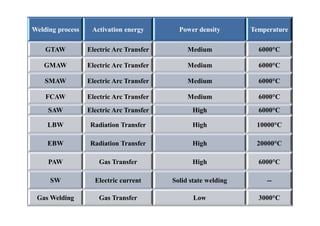

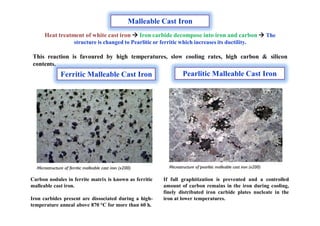

- The classification of commercial welding processes such as gas welding, arc welding, and high density beam welding.

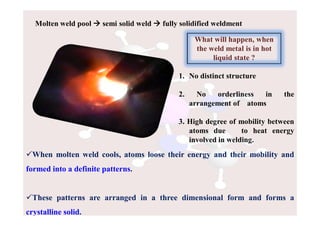

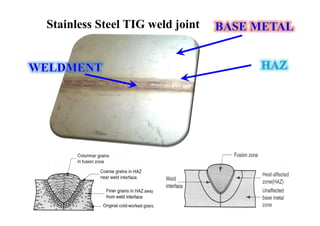

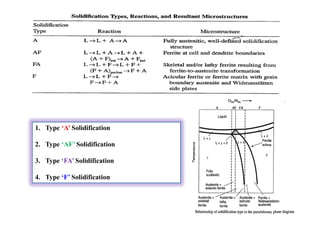

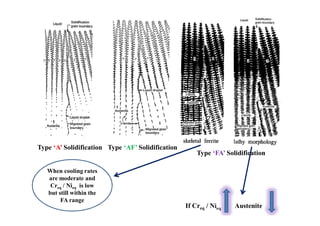

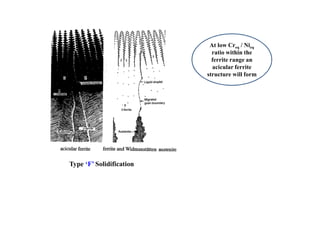

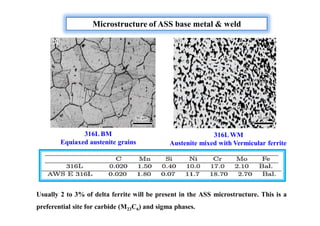

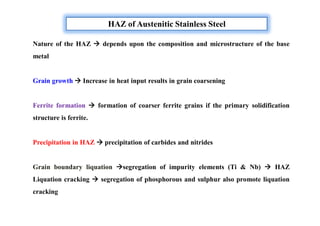

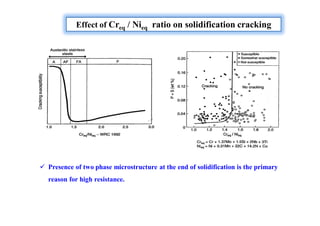

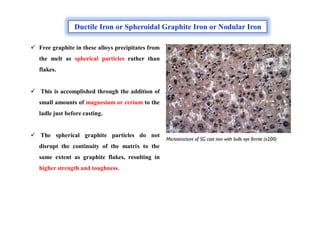

- How the microstructure of metals changes during the welding process as the weld metal transitions from liquid to solid states.

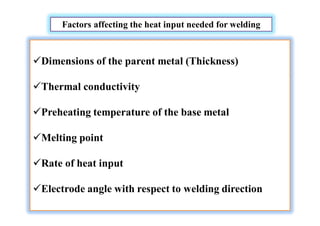

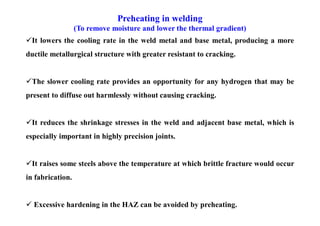

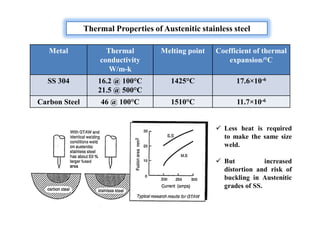

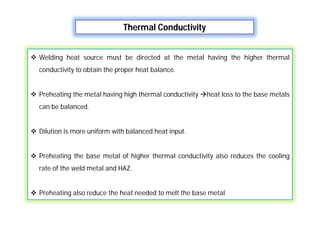

- Factors that influence the heat input required for welding like material thickness, thermal conductivity, and preheating temperature.

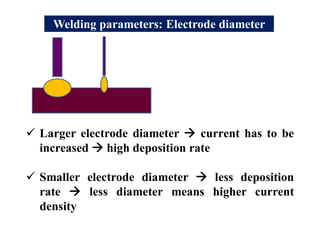

- Different welding parameters like current, voltage, speed, and electrode diameter and how they affect the weld bead.

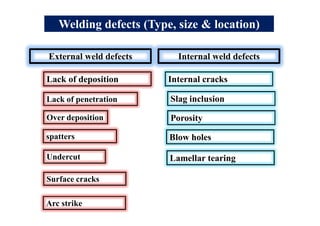

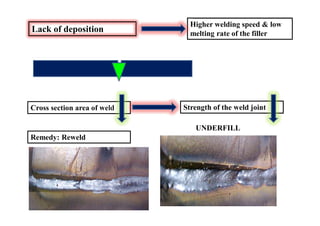

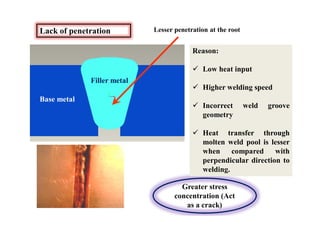

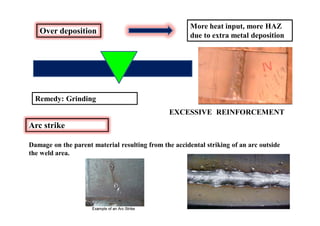

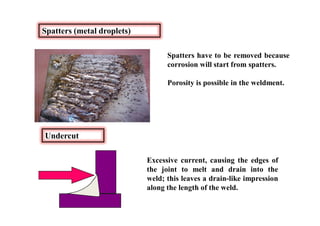

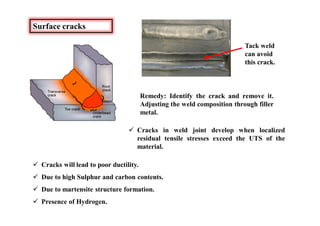

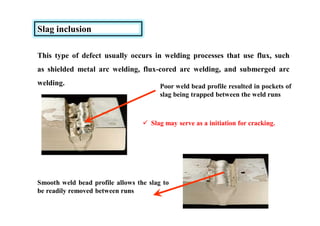

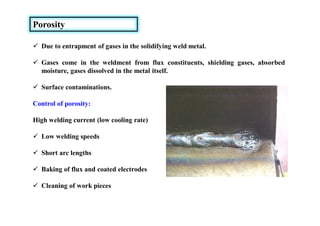

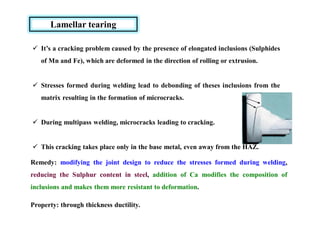

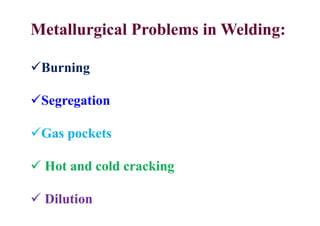

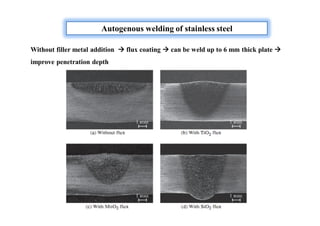

- Common weld defects such as lack of penetration, porosity, cracks and how to prevent them.

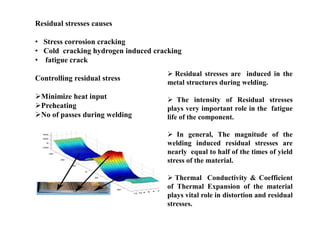

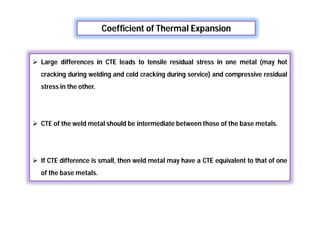

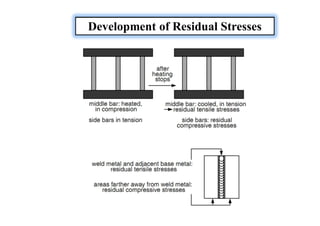

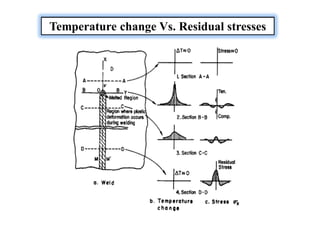

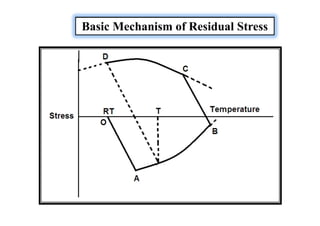

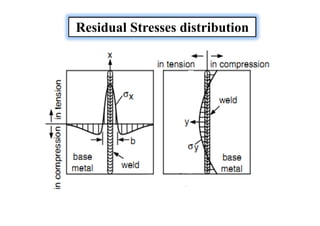

- How residual stresses are induced during welding

![Efficiency in welding and Heat input:

Where ,

Q = Heat transfer rate from the heat source to the work piece

Qnominal = Nominal power of the heat source

Always efficiency is less than one [η˂1] due to the lose of heat to the

surroundings during welding.

Where, E = Arc voltage; I = welding current and V = Welding speed

Heat input per unit length of the

weld

Q = EI/V](https://image.slidesharecdn.com/weldingtechnologybya-170922101945/85/Welding-technology-by-A-Vinoth-Jebaraj-25-320.jpg)

![Welding parameters: Welding Current [I]

Current heat Melting rate

Deposition rate

(Amount of filler

metal deposited)

Fusion zone

(Increasing the

penetrating power)

Increasing current will

lead to more effect on the

fusion zone penetration](https://image.slidesharecdn.com/weldingtechnologybya-170922101945/85/Welding-technology-by-A-Vinoth-Jebaraj-27-320.jpg)

![Welding parameters: Arc voltage [v]

Arc voltage α Arc length

Arc voltage

Arc length

Bead width

If arc length increases or decreases too much then arc becomes unstable.

L1

L2](https://image.slidesharecdn.com/weldingtechnologybya-170922101945/85/Welding-technology-by-A-Vinoth-Jebaraj-28-320.jpg)

![Welding parameters: Speed [s]

0.5 m/min

1.0 m/min

Welding speed

Decrease in penetration

Increase in bead width

Molten metal

has low

thermal

conductivity

High productivity,

less heat input, less

distortion and

residual stress](https://image.slidesharecdn.com/weldingtechnologybya-170922101945/85/Welding-technology-by-A-Vinoth-Jebaraj-29-320.jpg)

![Why Dissimilar welding is needed?

[For process system operate at different service conditions]

More resistible to

corrosion

More easy to process

and inexpensive

Wrought

structure

Wrought

structure

Cast structure](https://image.slidesharecdn.com/weldingtechnologybya-170922101945/85/Welding-technology-by-A-Vinoth-Jebaraj-113-320.jpg)

![Types of Residual Stresses

They are commonly classified into two groups:

Macro Residual stresses (Residual stresses of the first kind)

[Measured over a gauge length that encompasses several grains]

Micro Residual stresses (Residual stresses of the second kind)

[Measured within a single grain or a particular set of grains

Both types can contributing SCC or fatigue initiation depending upon the situation.](https://image.slidesharecdn.com/weldingtechnologybya-170922101945/85/Welding-technology-by-A-Vinoth-Jebaraj-136-320.jpg)

![Sources of Residual Stresses

Residual stresses owing to the shrinkage process of the Seam

and HAZ.

Residual stresses owing to the more rapid cooling of the surface

[quenching residual stresses]

Residual stresses owing to a phase transformation](https://image.slidesharecdn.com/weldingtechnologybya-170922101945/85/Welding-technology-by-A-Vinoth-Jebaraj-139-320.jpg)