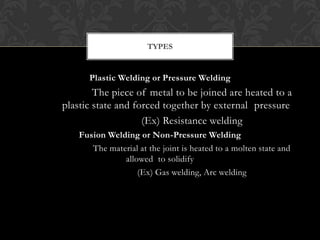

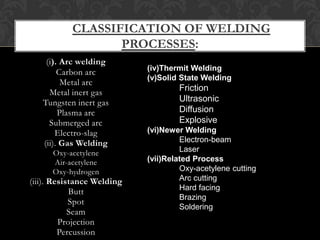

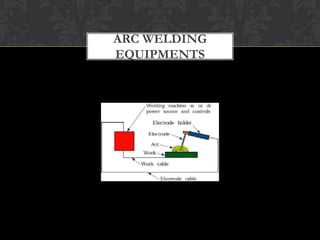

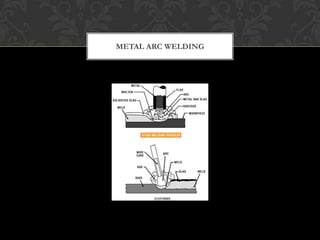

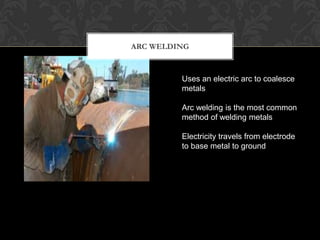

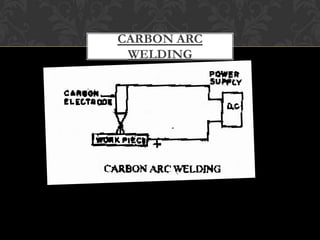

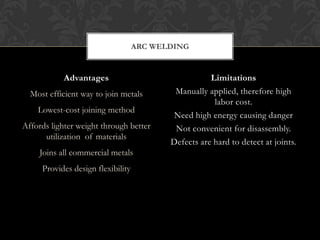

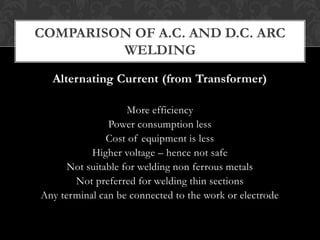

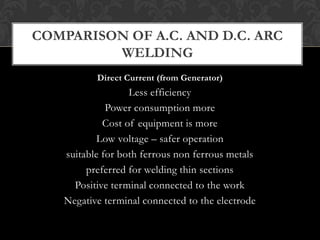

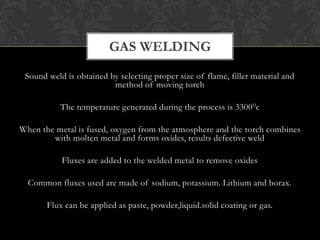

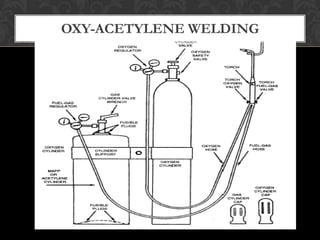

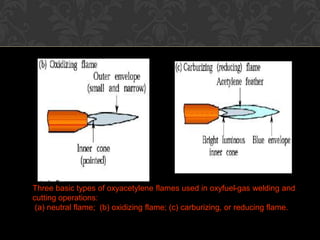

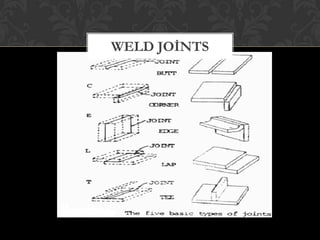

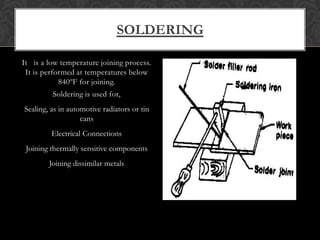

Welding is a process that joins materials by heating them to melt or soften them and allowing them to coalesce. It is used to join metal components in industries like automotive, aerospace, shipbuilding and more. There are several types of welding processes including arc welding, gas welding, resistance welding, and newer techniques like laser beam and electron beam welding. Arc welding uses an electric arc to generate heat and melt the metals, and is one of the most common welding methods. Gas welding uses a flame from oxygen and fuel gases to heat and join metals. Brazing and soldering are similar lower-temperature processes that join materials without fully melting them.