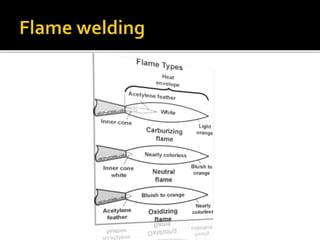

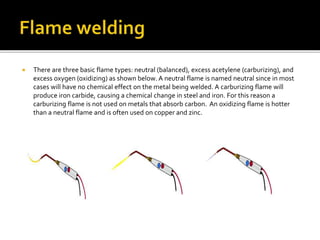

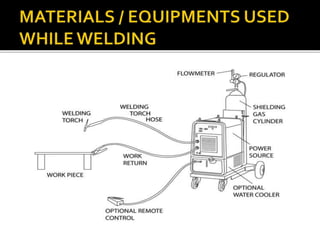

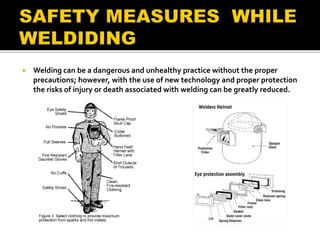

The document discusses various welding processes including arc welding, gas welding, plastic welding, and fusion welding. It provides details on common arc welding techniques like shielded metal arc welding, submerged arc welding, and gas metal arc welding. The document also covers gas welding processes using oxy-acetylene, oxy-hydrogen, and air-acetylene flames. It discusses the equipment, applications, advantages and disadvantages of different welding methods.

![ Ox hydrogen is a mixture of hydrogen (H2) and oxygen (O2) gases.This gaseous mixture is

used for torches to process refractory materials and was the first[1] gaseous mixture used

for welding. Theoretically, a ratio of 2:1 hydrogen: oxygen is enough to achieve maximum

efficiency; in practice a ratio 4:1 or 5:1 is needed to avoid an oxidizing flame.[2]](https://image.slidesharecdn.com/welding-160721175529/85/Welding-presentation-13-320.jpg)