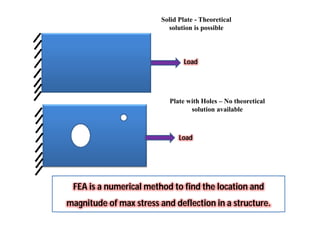

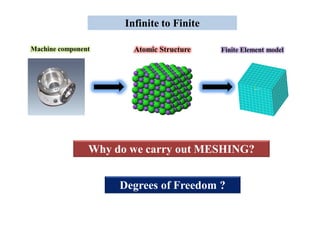

This document discusses finite element analysis (FEA) and its applications in engineering design. It covers topics such as:

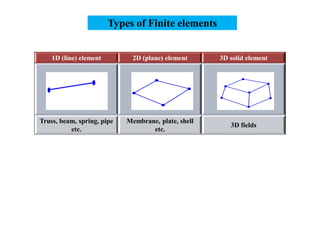

- The different types of analyses that can be done, including 1D, 2D, and 3D analysis

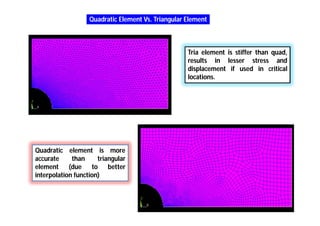

- The types of finite elements that can be used, such as beam, shell, and solid elements

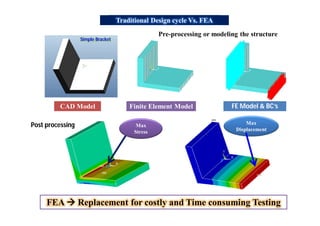

- How FEA can be used as a replacement for physical testing in the design process

- Key steps in pre-processing and post-processing FEA models

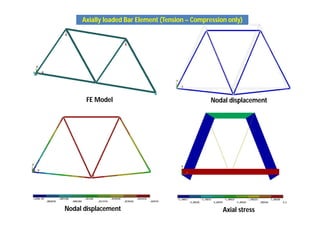

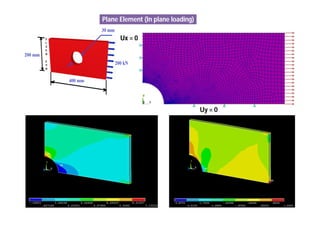

- Examples of how different elements model stresses, including axial, bending, torsional, and plane stresses