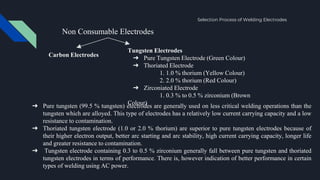

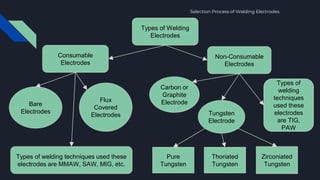

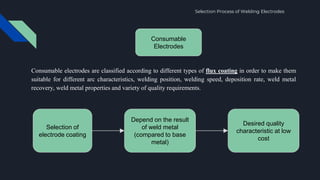

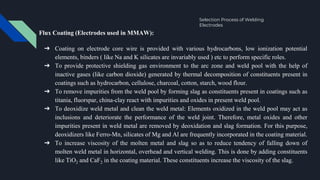

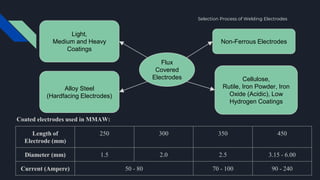

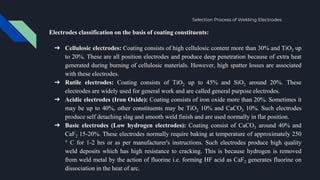

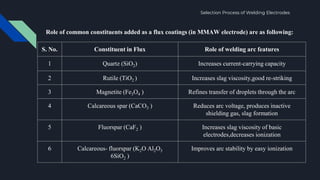

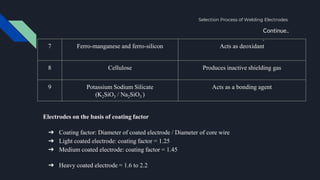

This document discusses the selection process for different types of welding electrodes. It describes consumable electrodes that are classified based on their flux coatings to suit different arc characteristics, welding positions, and quality requirements. The key types of flux coatings include cellulosic, rutile, iron oxide, and basic low-hydrogen coatings. Important constituents in flux coatings like TiO2, CaCO3, and CaF2 are outlined. Guidelines for selecting electrode size based on current and coating factor are also provided. Classification systems for coated electrodes and guidelines for selecting between pure, thoriated, and zirconiated tungsten electrodes are summarized.

![Selection Process of Welding Electrodes

Designation of Coated Electrodes:

First two digits of four digit numbers and the first three digits of five digit numbers indicate

minimum tensile strength:

➔ E60XX, 60,000 psi minimum tensile strength

➔ E70XX, 70,000 psi minimum tensile strength

➔ E110XX, 110,000 psi minimum tensile strength

Third digit indicates position:

➔ EXX1X, All position

➔ EXX2X, Flat positions and horizontal fillets

Last two digit (including third) indicates type of coating and current

Fig. 1. Designations [3]](https://image.slidesharecdn.com/selectionprocessofweldingelectrodes-fornet-180621093117/85/Selection-process-of-welding-electrodes-9-320.jpg)