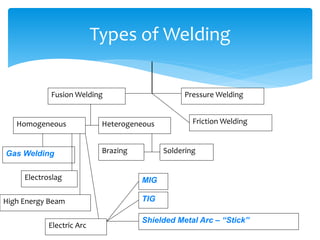

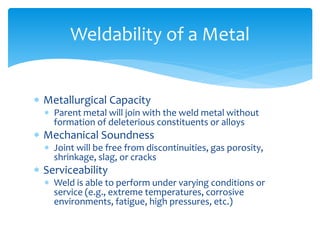

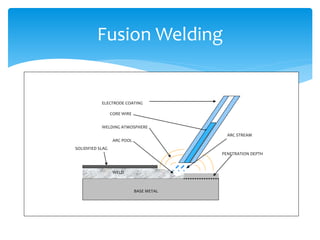

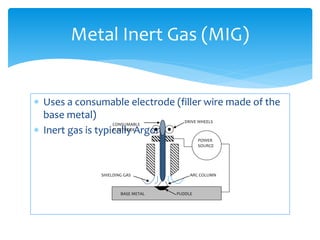

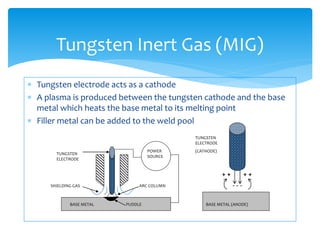

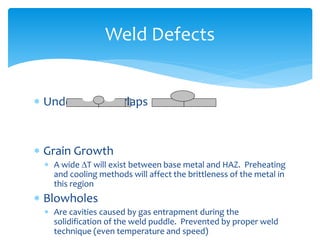

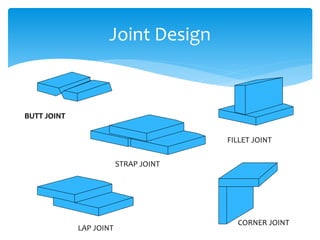

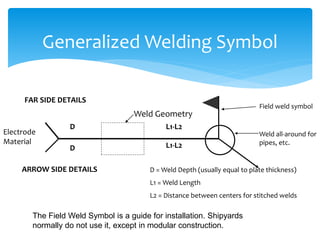

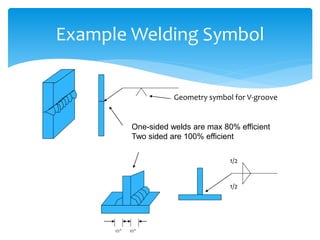

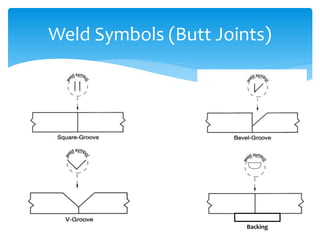

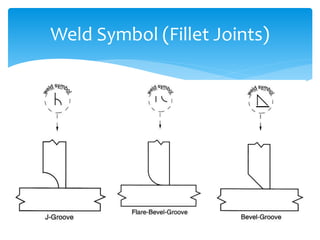

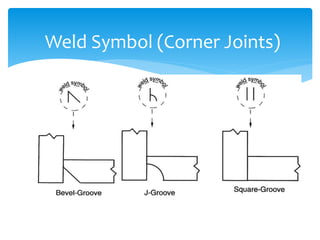

Welding has evolved significantly since the late 19th century when scientists first applied electricity to join metals. During World War II, welding gained widespread acceptance and was used extensively in shipbuilding and manufacturing. Modern welding brings various techniques from an art to a science, including fusion welding processes like shielded metal arc welding, gas metal arc welding, and gas tungsten arc welding. Proper joint design and welding technique are needed to minimize defects and residual stresses in welded joints. Standard welding symbols are used to specify weld sizes, locations, materials and other details.