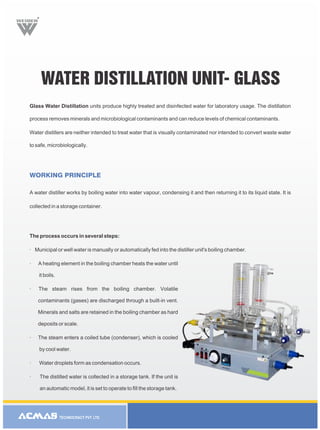

The r technocracy pvt. ltd. water distillation unit (glass model no. acm-54093-w) produces high-quality distilled water by boiling and condensing water, effectively removing contaminants. The unit operates on single-phase AC supply and is equipped with features like an automatic low water level cut-off device and various flask capacities. It adheres to quality standards like ISO 9001 and offers technical specifications such as conductivity and pH for distilled water output.