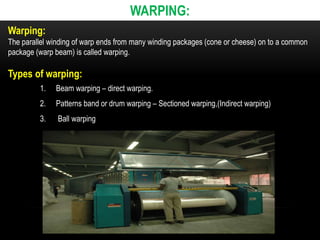

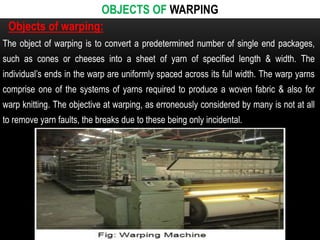

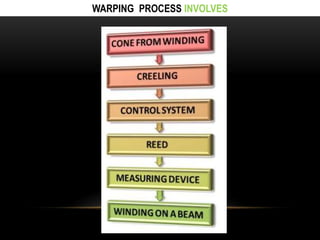

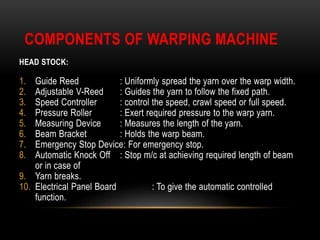

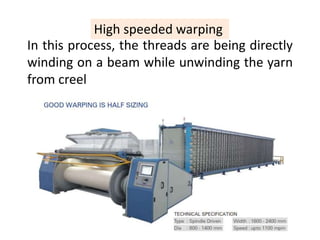

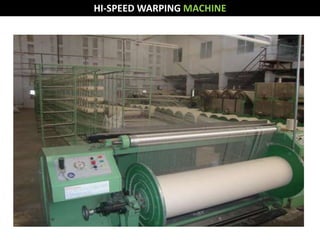

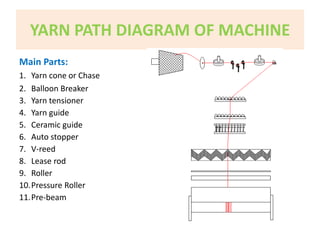

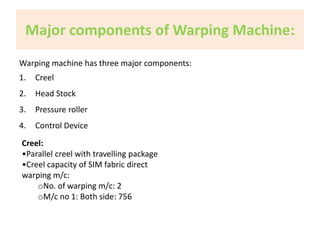

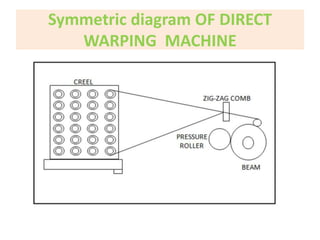

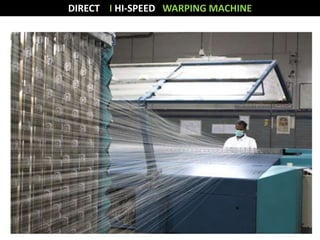

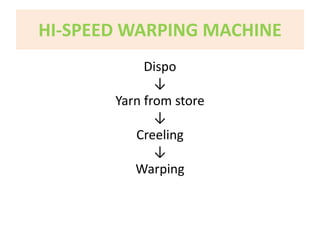

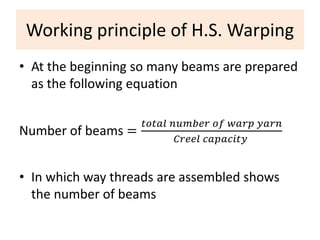

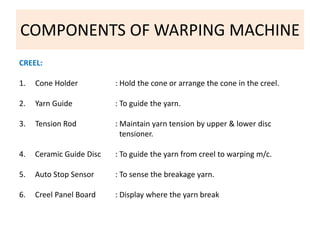

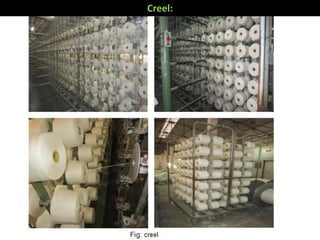

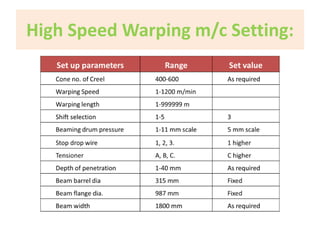

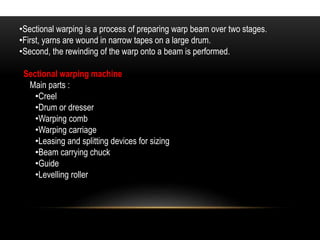

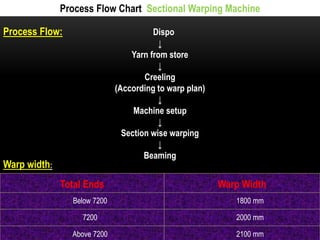

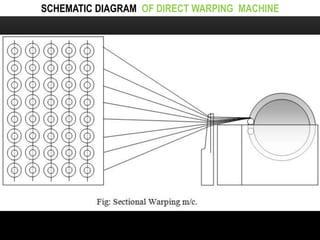

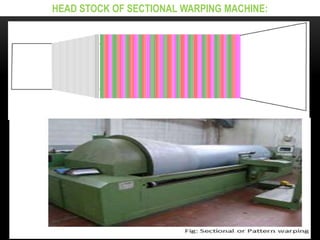

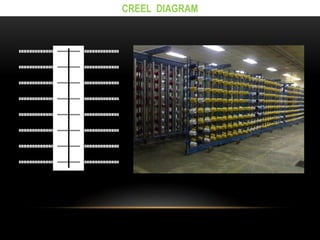

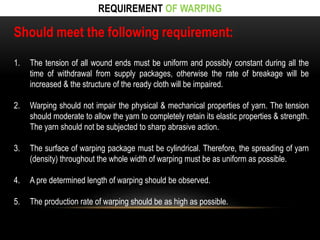

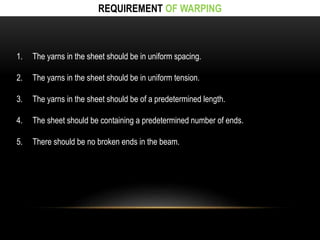

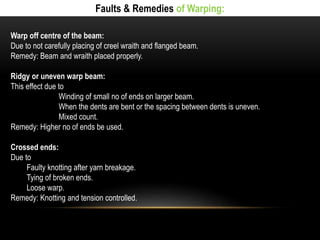

The document discusses different types of warping processes and machines. It describes beam warping, sectional or patterned warping, and ball warping. Beam warping is direct warping that produces beams with up to 1000 ends, while sectional warping is indirect and produces narrow tapes that are later rewound onto a beam, allowing for complex patterns. High-speed warping machines directly wind ends onto a beam from many packages at once. Sectional warping machines first wind yarns onto a drum before rewinding them onto a beam, enabling fancy multi-colored fabrics. Both processes aim to produce a warp beam with uniformly spaced, tensioned ends of a predetermined length.