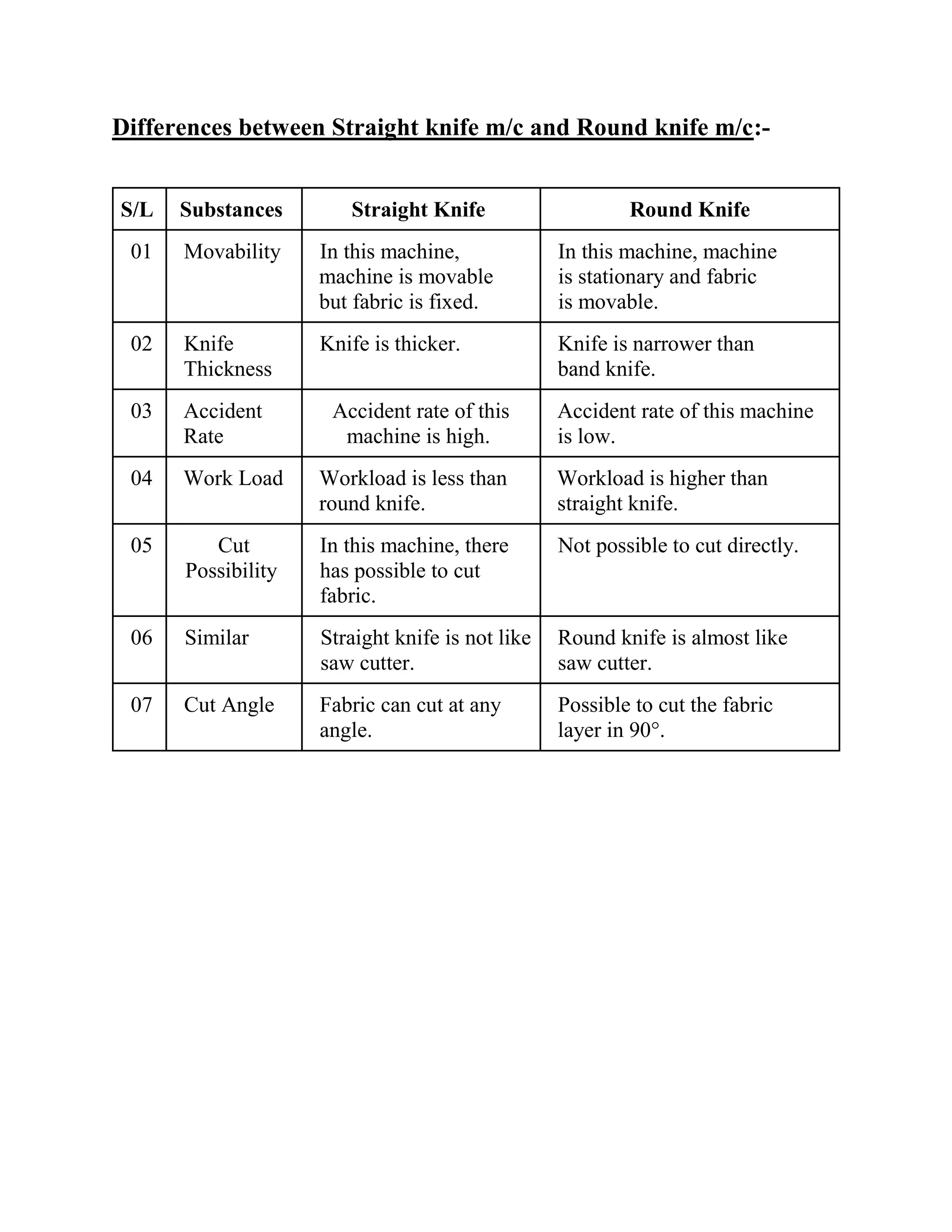

This lab report summarizes the student's study of straight knife and round knife cutting machines. The straight knife machine uses a straight blade to cut large pieces and curves, while the round knife machine uses a round blade and is better for small-scale cutting and gentle curves. Key differences are that the straight knife can cut fabrics from any angle, has higher productivity, but requires more skill, while the round knife is easier to use but can only cut at 90 degree angles. Both machines require regular blade sharpening and cleaning to maintain optimal performance.