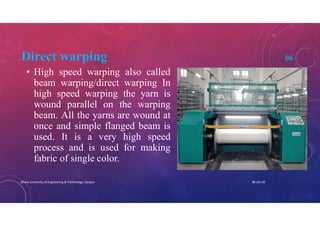

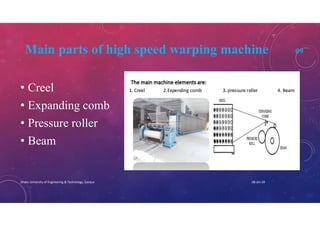

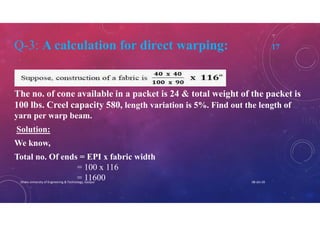

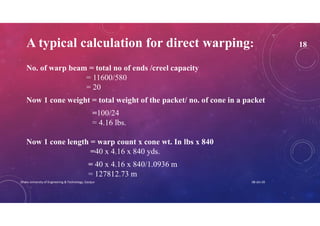

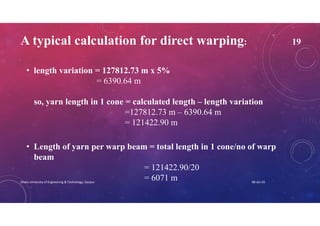

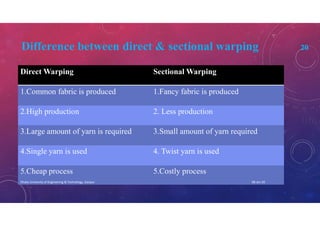

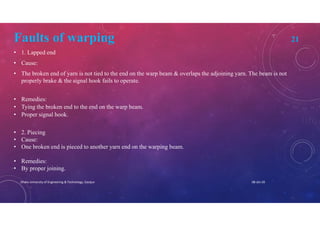

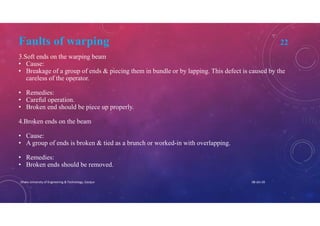

The document presents a comprehensive study on direct warping in textile engineering, detailing its definition, types, requirements, and the working principles of a high-speed warping machine. It covers the advantages and disadvantages of direct warping, along with typical calculations, components, and methods to improve the warping process. Furthermore, it discusses common faults in warping and their remedies.